Pressurized-water nuclear reactor structure

A nuclear reactor, pressurized water type technology, applied in nuclear reactors, nuclear reactor monitoring, reactors, etc., can solve the problems of poor cooling effect of pressure vessels, increased number of measuring tube sockets, unreasonable design, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

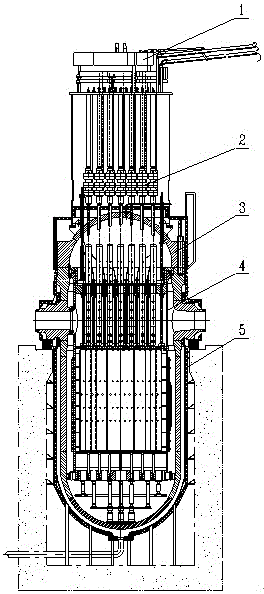

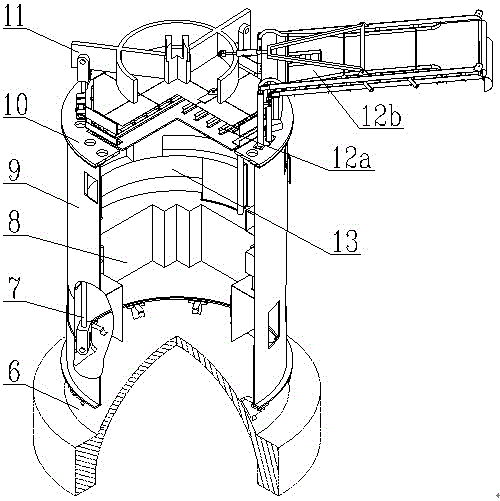

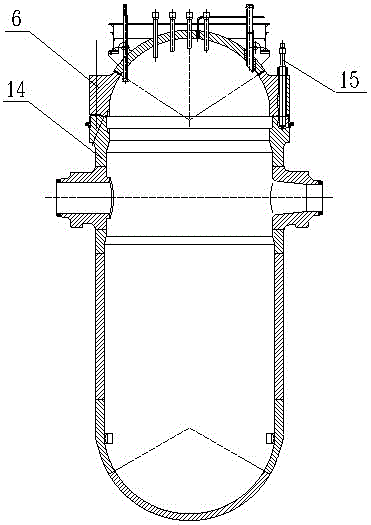

[0028] In embodiment one, a pressurized water nuclear reactor structure is provided, please refer to Figure 1-Figure 7 , the structure includes:

[0029] Integrated stack top 1, drive mechanism 2, pressure vessel 3, stack internal components 4, heat preservation components 5, the integrated stack top is connected to the pressure vessel top cover 6, and the heat preservation components are arranged outside the pressure vessel On the surface, the internal components of the pile are hung on the support steps of the pressure vessel, and the driving mechanism is installed on the top cover of the pressure vessel, wherein the integrated pile top specifically includes: a lower boom 7, a cooling shroud 8. Shroud 9, anti-seismic component 10, top cover hanger 11, cable bracket 12a, cable bridge assembly 12b, cooling air duct 13, wherein, the lower boom and the cooling air duct are installed on the enclosure Inside the cylinder, the lower suspender is connected to the lifting lug on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com