Fixing pressing piece for solar cell module

A solar cell and module technology, applied in electrical components, photovoltaic power generation, photovoltaic modules, etc., can solve the problems of increased maintenance time and labor, inability to install, large labor and time, etc., to shorten installation time, improve installation applicability, The effect of simplifying on-site installation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

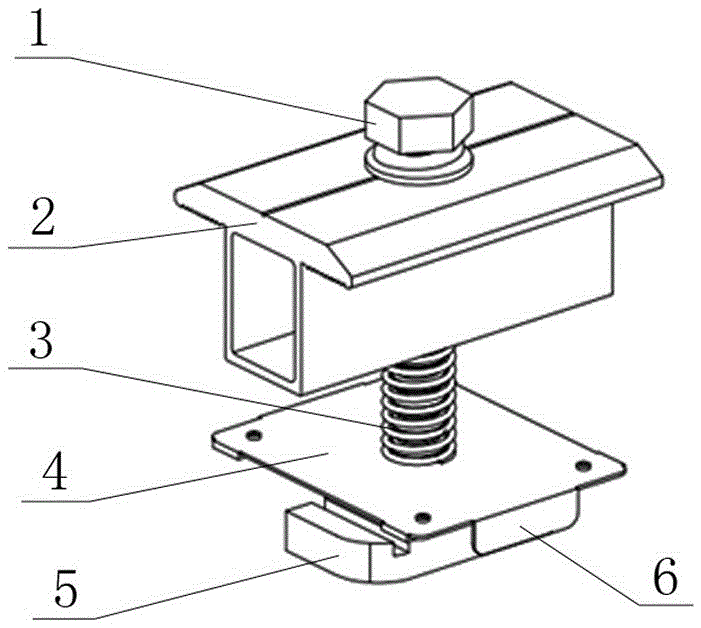

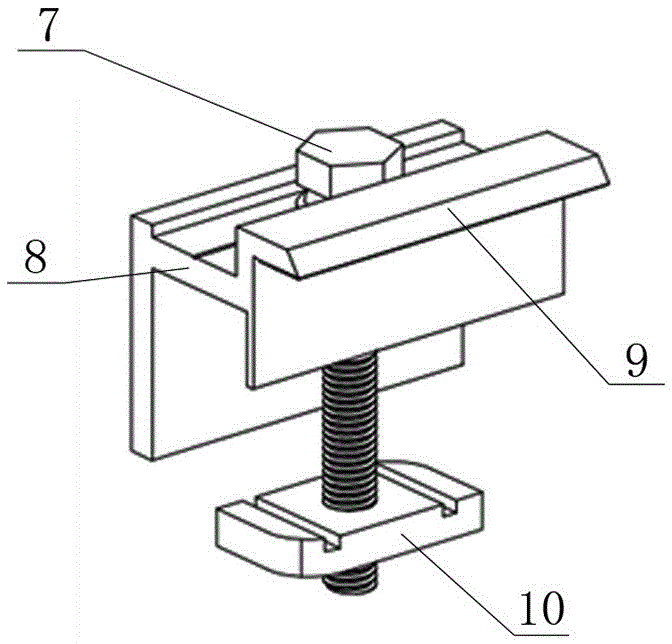

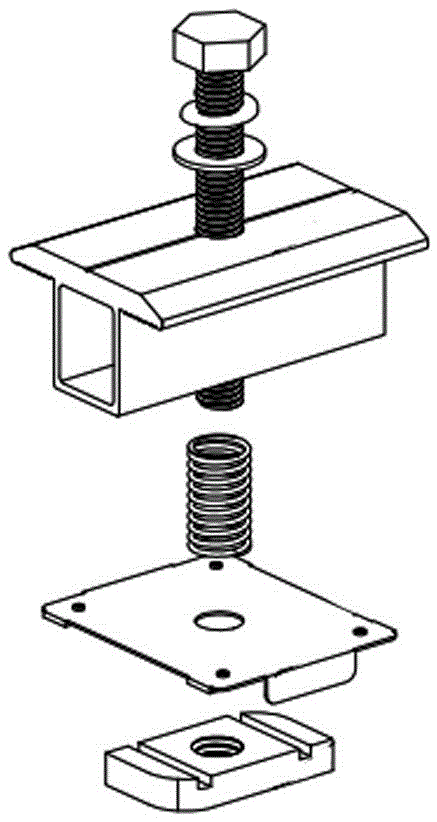

[0018] As shown in the accompanying drawings, a fixed pressing block for a solar cell module includes a middle pressing block 11 and an edge pressing block 14, and the middle pressing block 11 is used for fixed connection of two adjacent solar battery modules 12 (such as Figure 7 shown), the side pressure block 14 is used for the fixed connection of the solar battery modules 15 on both sides (such as Figure 8 shown), the middle pressure block 11 (such as figure 1 shown) includes bolt 1, T-shaped pressing block main body 2, spring 3, grounding plate 4 and slider nut 5, and the two adjacent solar cell modules 12 are stuck on both sides of T-shaped pressing block main body 2 and connected to the grounding plate 4, one side of the ground sheet 4 is provided with a spike 6; the side pressing block 14 (such as figure 2 (shown) includes a bolt 7 , a briquetting body 8 and a slider nut 10 , the briquetting body 8 is provided with a folded edge 9 on one side, and the folded edge 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com