Metering module for metering AdBlue

A technology of metering device and injection valve, which is applied in exhaust gas treatment, mechanical equipment, engine components, etc., and can solve problems such as the maximum allowable temperature limit of metering module

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

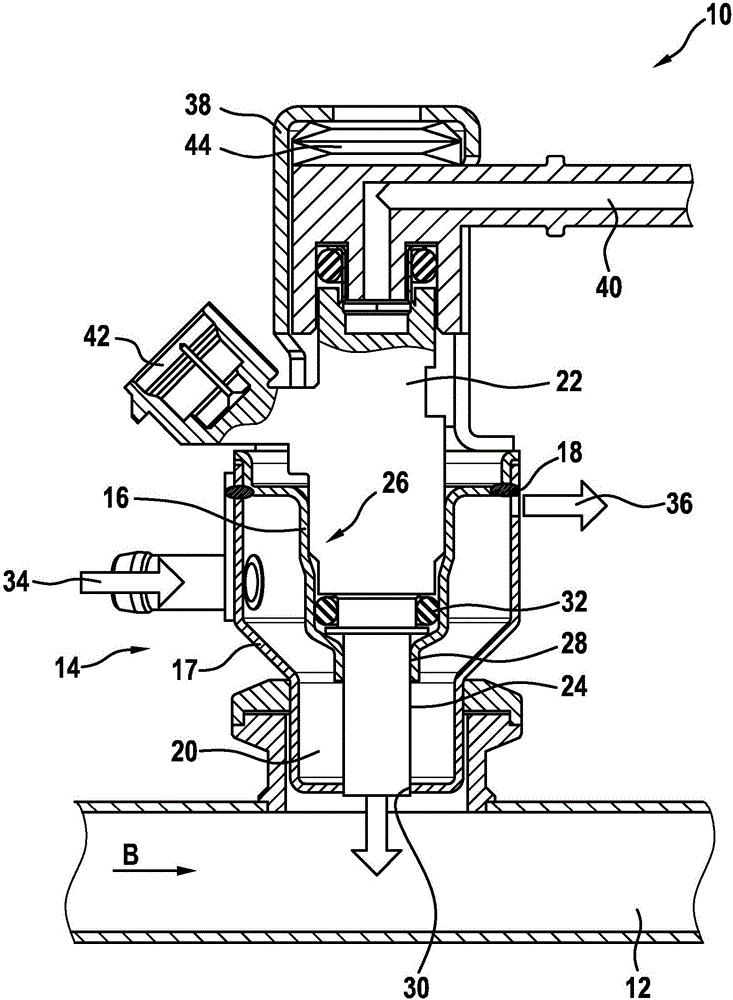

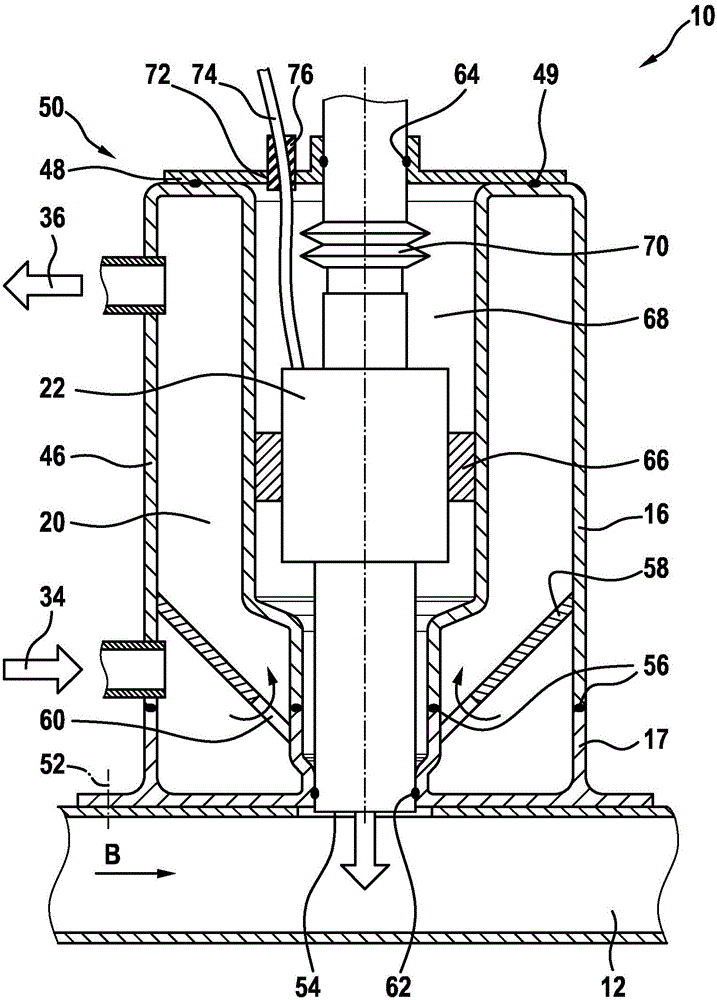

[0024] figure 1 Shown is a metering device 10 which is used in an SCR system for metering reducing agent into an exhaust line 12 , wherein the exhaust gas flow flows in a flow direction B through the exhaust line 12 . The exhaust stream comes from figure 1In an internal combustion engine, not shown, the exhaust pipe 12 adjoins the internal combustion engine on its discharge side. The metering device 10 comprises a base body 14 , which is formed from a first sheet metal 16 and a second sheet metal 17 , which are connected to one another in an abutment region or overlapping region by a soldered connection 18 . The plates 16 and 17 are spaced apart from each other and form an annular cavity 20 . Furthermore, an injection valve 22 , the housing of which is designated 24 , is accommodated in the base body 14 . The contour of the first metal sheet 16 is selected such that an adaptive receptacle 26 for the injection valve 22 is formed. The injection valve 22 forms an abutment reg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com