Insulator cleaning robot mechanism

A technology for cleaning robots and cleaning mechanisms, applied to chemical instruments and methods, cleaning methods and utensils, cleaning methods using tools, etc., can solve problems such as low cleaning efficiency and complicated cleaning mechanisms, and achieve flexible and reliable operations and stable movement Reliable, adaptable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

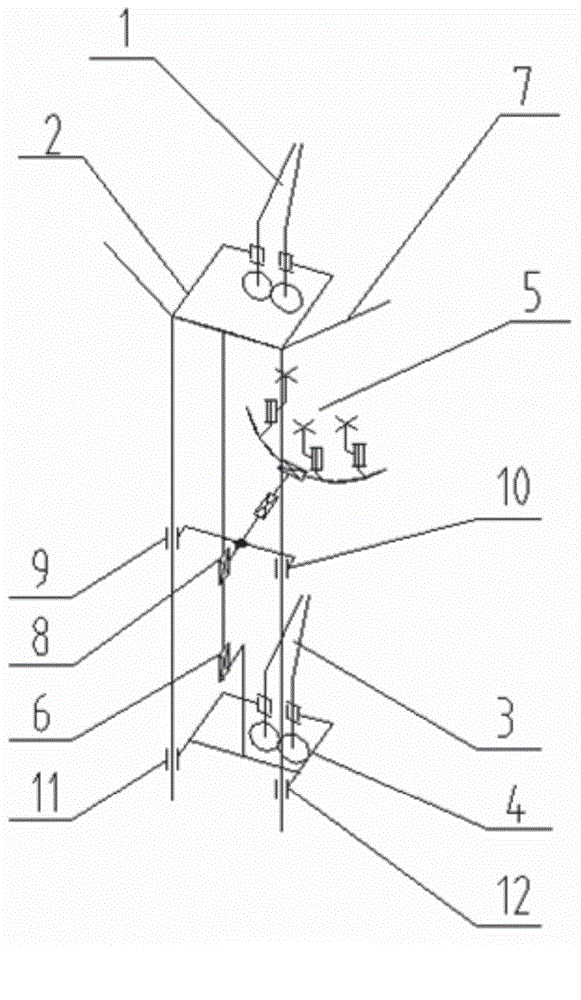

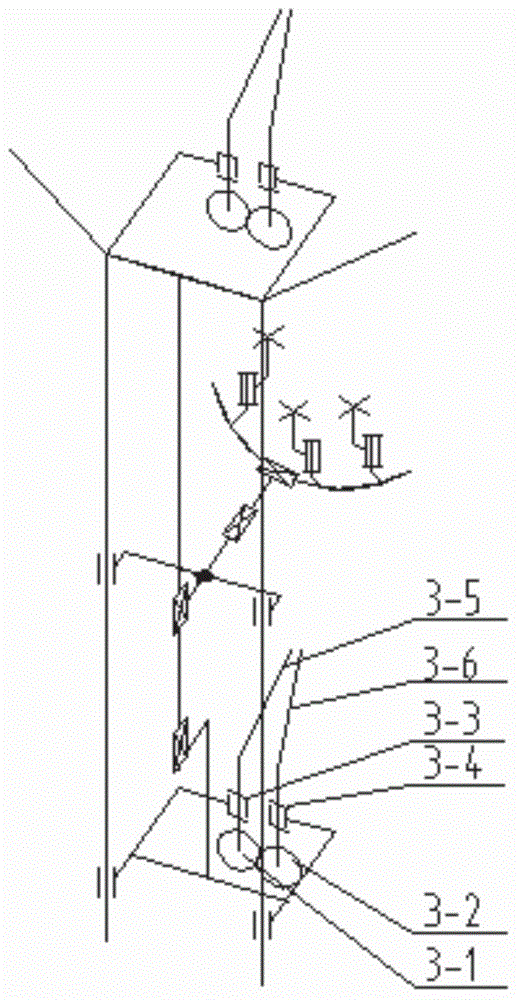

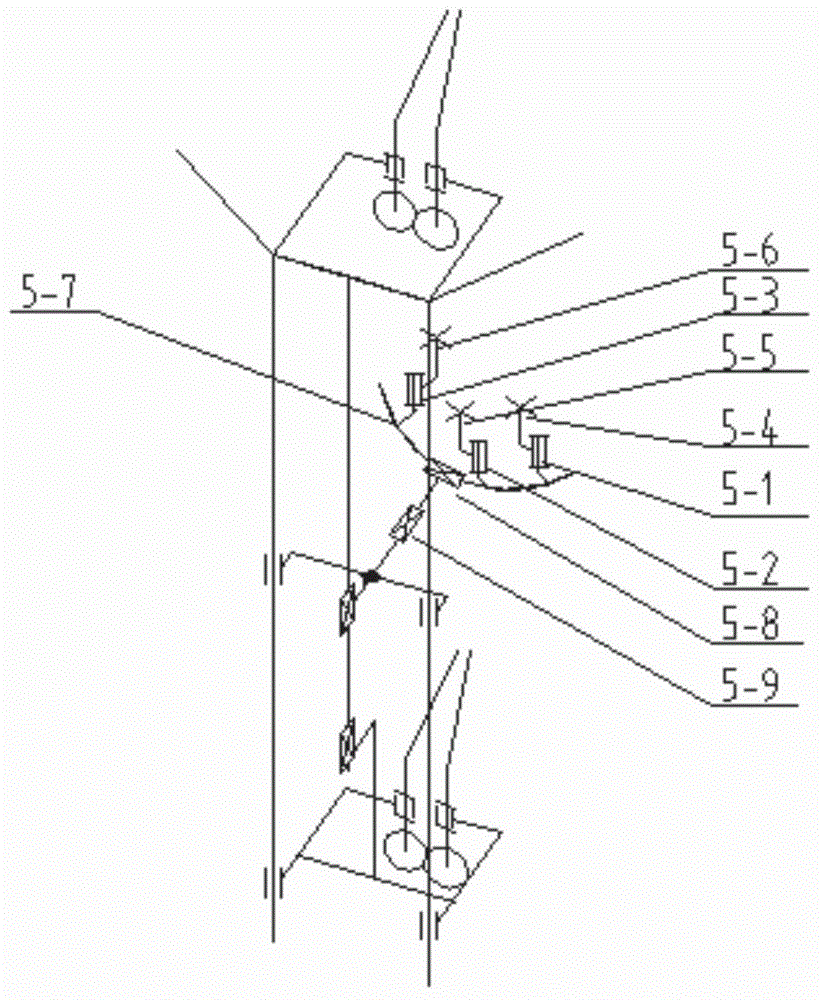

[0027] Such as figure 1 Shown, the present invention comprises upper jaw 1, upper frame 2, lower jaw 3, lower frame 4, cleaning mechanism 5, first movable joint 6, frame 7 and second movable joint 8, wherein upper frame 2 and machine The frame 7 is fixedly connected, and the lower frame 4 is slidably connected with the frame 7 through the seventh moving joint 11 and the eighth moving joint 12 (the way that the slide block cooperates with the guide rail), and the seventh moving joint 11 and the eighth moving joint 12 are placed vertically and are joints for passive movement. The lower frame 4 is connected to the upper frame 2 through the first vertical moving joint 6 , and the upper jaw 1 and the lower jaw 3 are respectively arranged on the upper frame 2 and the lower frame 4 . The cleaning mechanism 5 is connected with the upper frame 2 through the second m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com