A fully automatic crane control system, method and a fully automatic crane

A control method and fully automatic technology, which is applied to load hanging components, cranes, traveling bridge cranes, etc., can solve problems such as unsmooth operation, low construction efficiency, and long working hours, so as to improve compatibility and applicability range, increase production or construction efficiency, and reduce the effect of switching steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, so they are only examples, and should not be used to limit the protection scope of the present invention.

[0067] It should be noted that, unless otherwise specified, the technical terms or scientific terms used in this application shall have the usual meanings understood by those skilled in the art to which the present invention belongs.

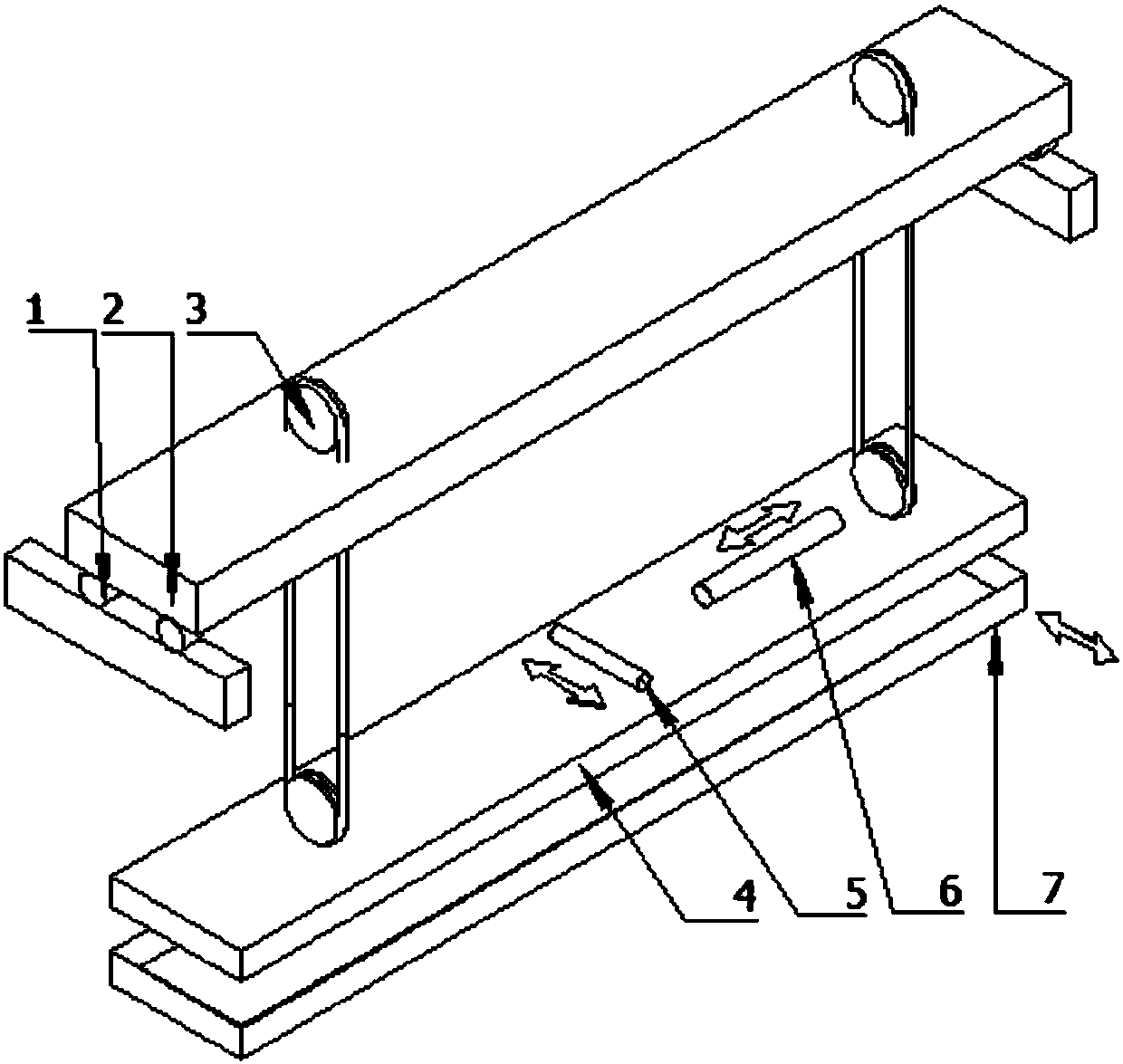

[0068] For easy understanding, this part briefly introduces the structure of the crane, please refer to figure 1 , which is a structural schematic diagram of a crane provided in the first embodiment of the present invention. The crane includes: a cart 1, a beam 2, a main lifting mechanism 3, a spreader 4, a plate lock 5, a slot Push rod 6 and liquid receiving tray 7;

[0069] W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com