A waste recovery tail water treatment device

A water treatment device and waste technology, which is applied in multi-stage water treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., to achieve the effect of complete separation, high efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

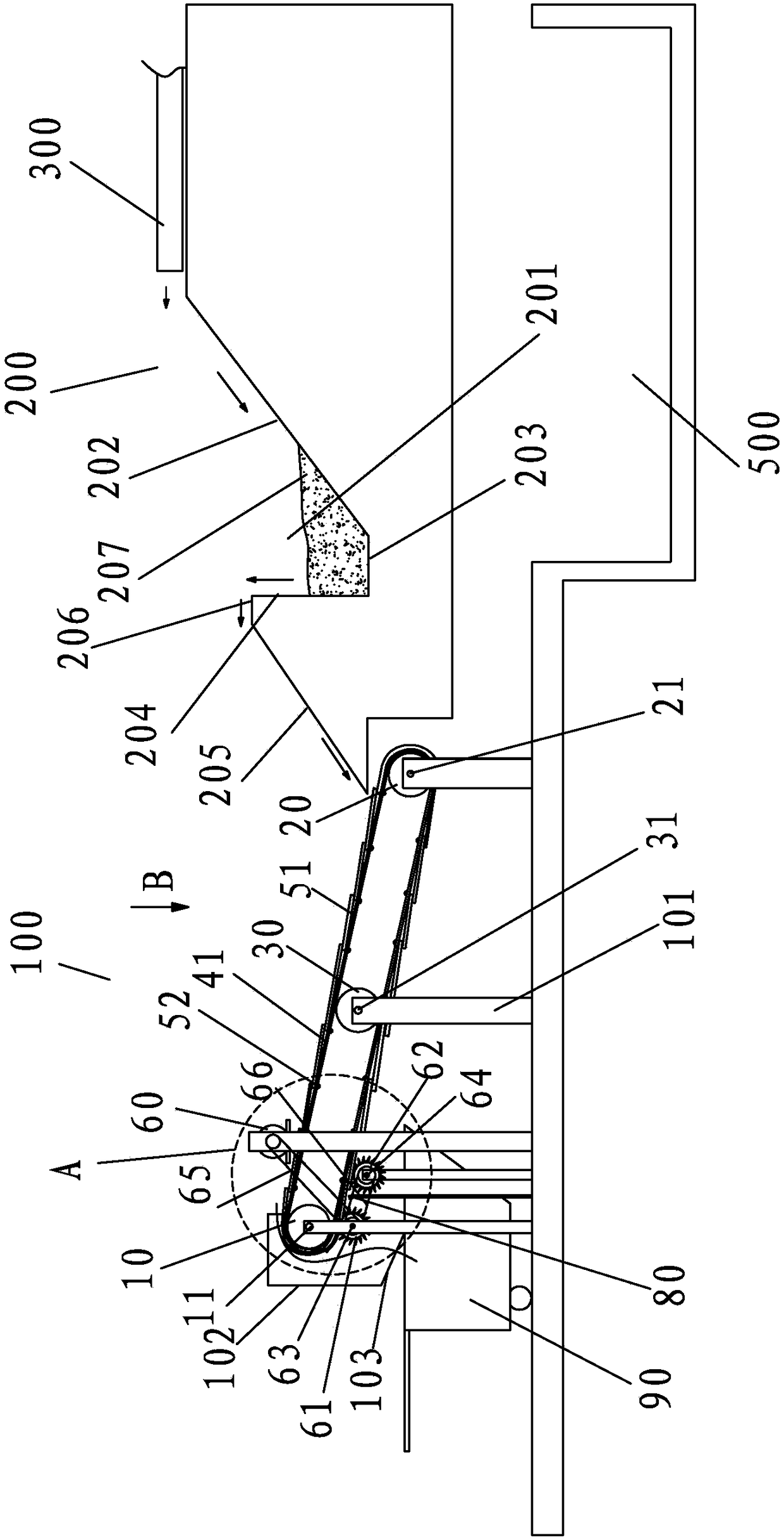

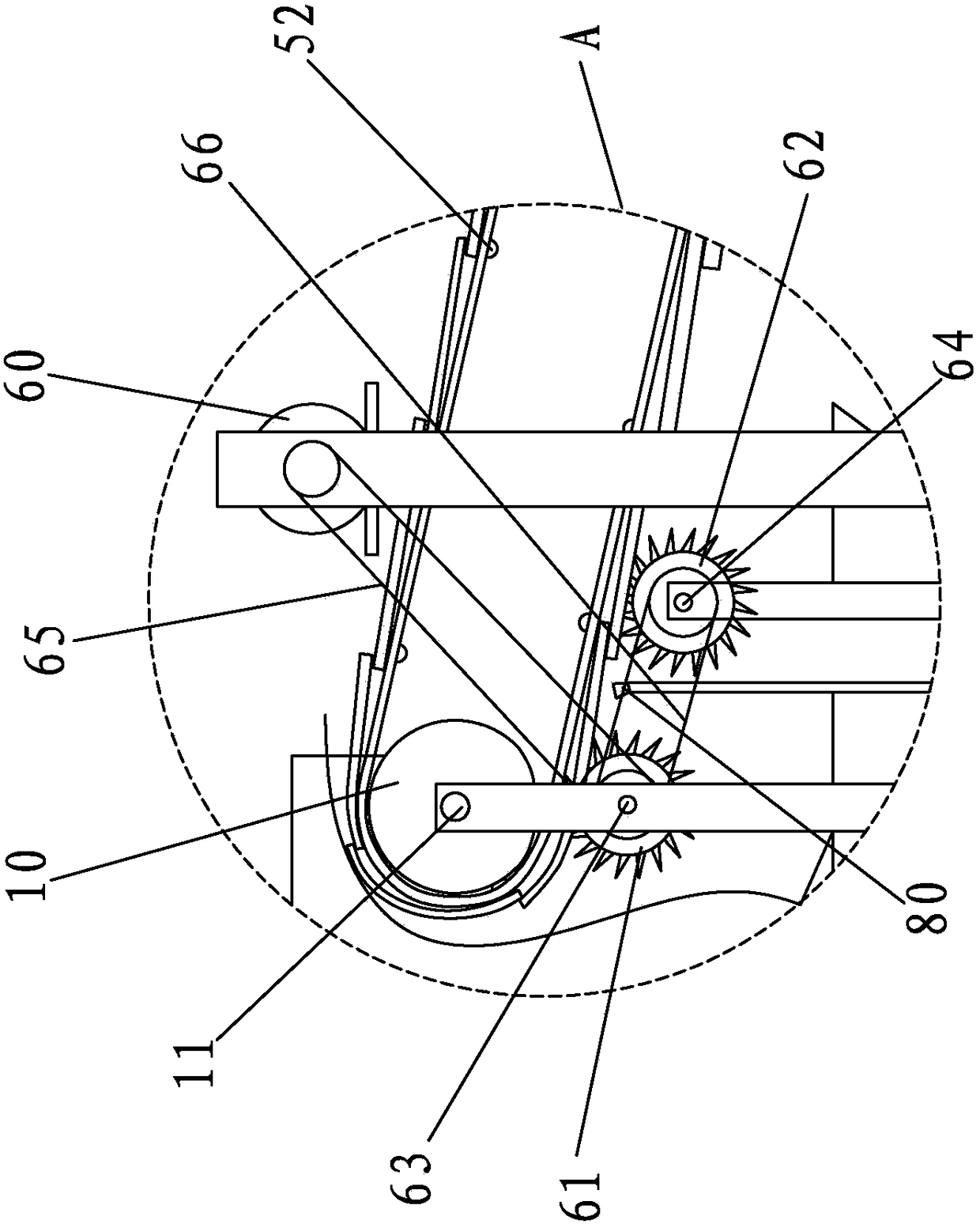

[0055] In order to further explain the technical solution of the present invention, it will be described in detail below in conjunction with the accompanying drawings.

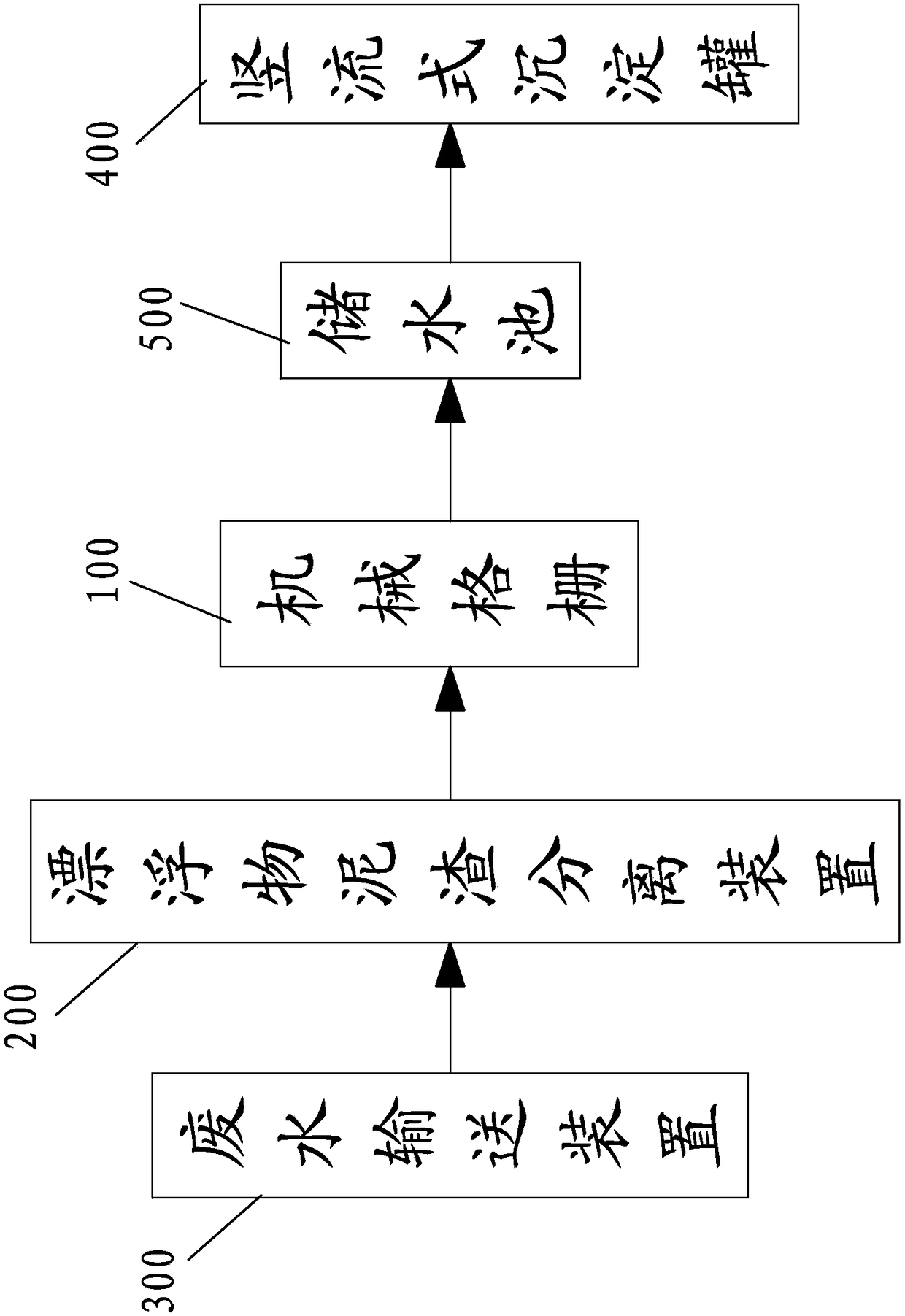

[0056] refer to Figures 1 to 6 , a tail water treatment device for waste recovery, a waste water conveying device 300, a floating matter and slag separating device 200, a mechanical grid 100 and a vertical flow sedimentation tank 400, the outlet end of the waste water conveying device 300 and the floating and slag separating device 200 The water inlet is connected, the water outlet of the floating debris and slag separation device 200 is connected with the water inlet of the mechanical grille 100, and the water outlet of the mechanical grille 100 is connected with the water inlet of the vertical flow sedimentation tank 400. In the embodiment, the water outlet end of the mechanical grill 100 is connected to the water storage tank 500, and the water storage tank 500 is connected to the vertical flow sedimentati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com