A recovery and treatment device for oily sewage after cleaning aluminum profile extrusion dies

A technology for extrusion dies and sewage recycling, applied in water/sewage treatment, multi-stage water/sewage treatment, heating water/sewage treatment, etc., can solve problems such as shortages, achieve low cost, increase contact time, and enhance adsorption effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

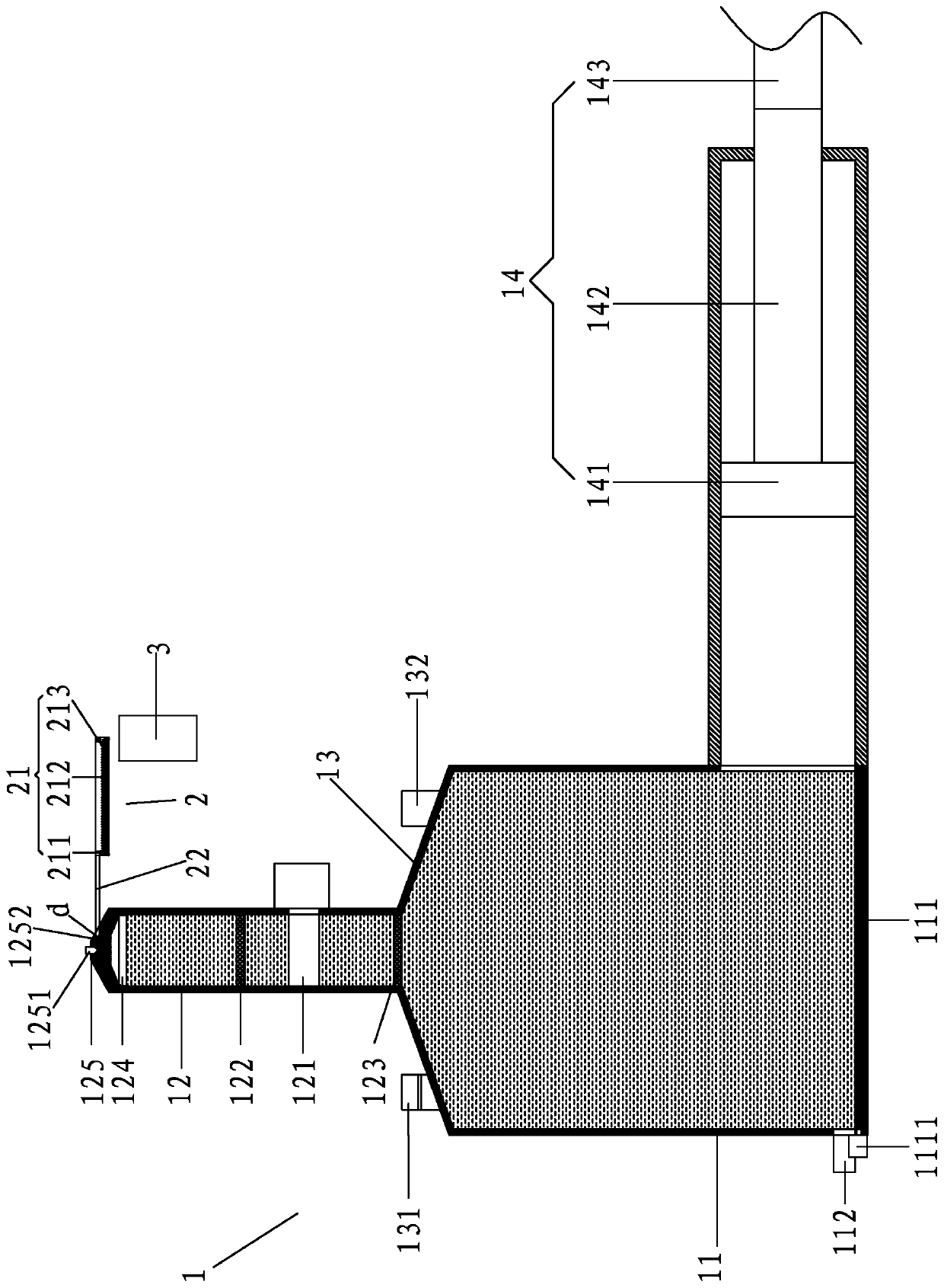

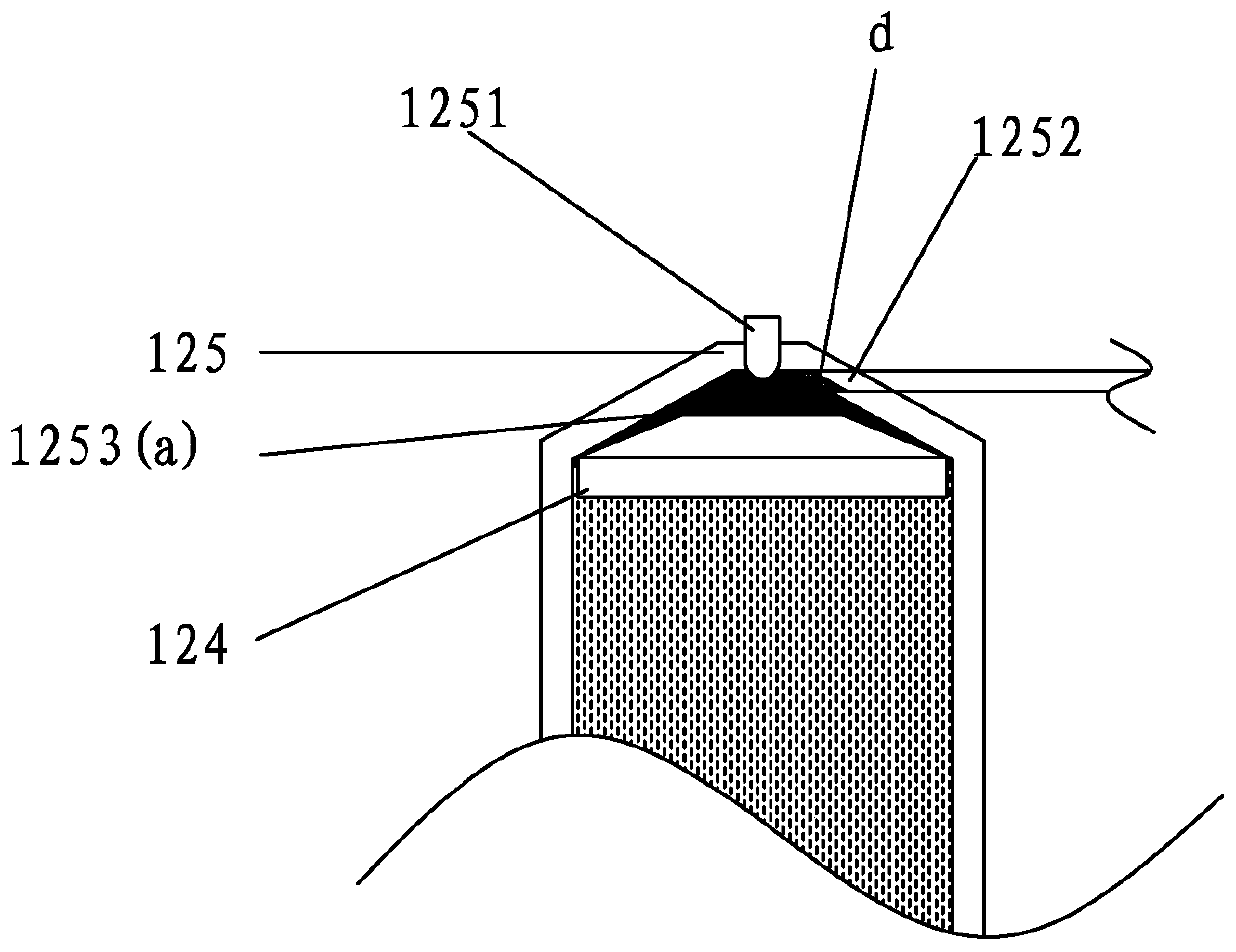

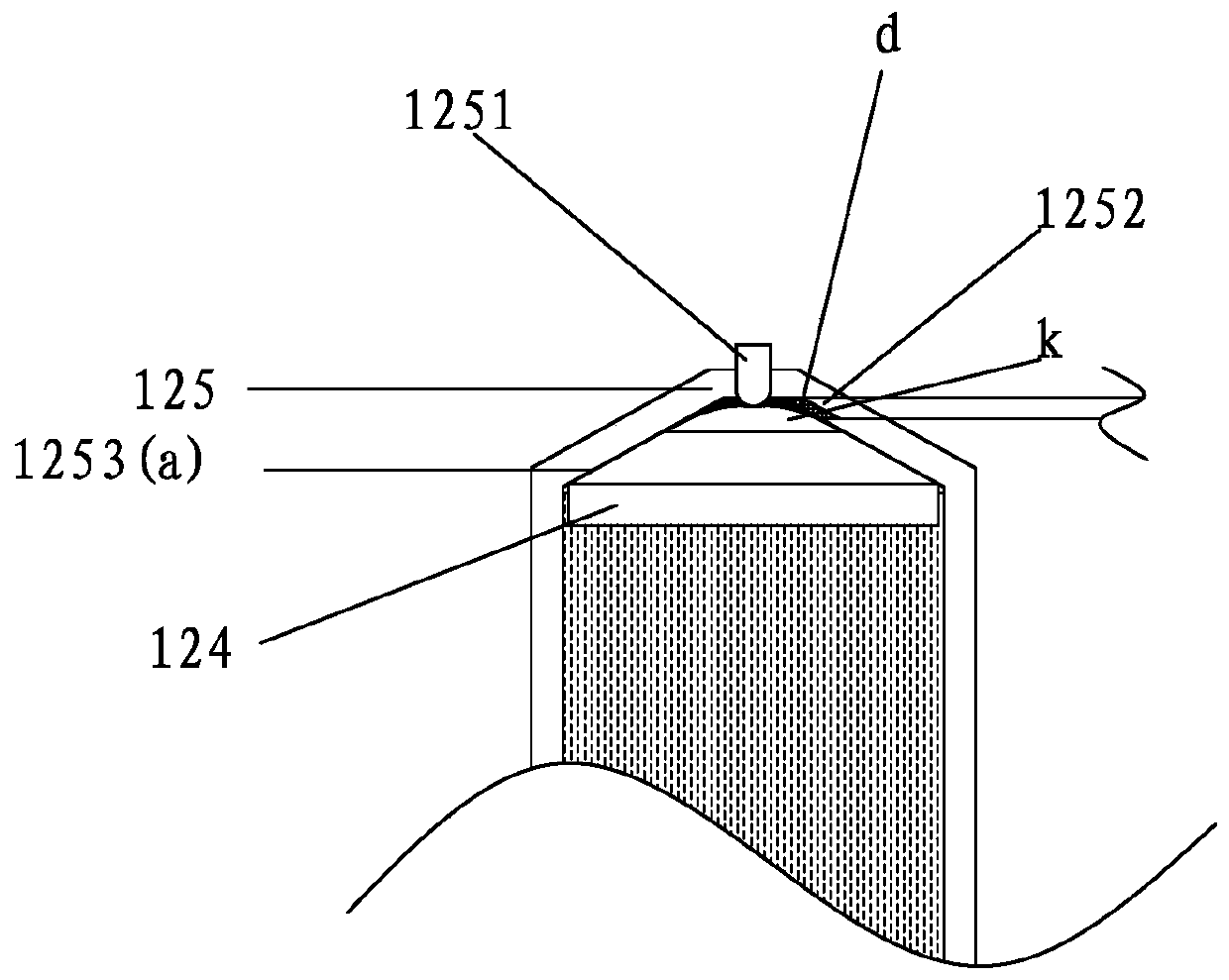

[0053] A device for recovering and treating oily sewage after the aluminum profile extrusion die is cleaned, such as Figure 1-7 As shown, along the oily sewage treatment line, the gravity separation mechanism 1, the slow flow sedimentation mechanism and the oil collection tank are sequentially included.

[0054] The gravity separation mechanism 1 comprises a barrel body 11 containing oily sewage and having a relatively thick diameter, an oil-collecting thin-diameter tube 12 with a thinner diameter arranged on the upper end of the barrel body 11, connected between the barrel body 11 and the oil-collecting thin-diameter tube 12 and A tapered transition section 13 that gradually becomes thicker from top to bottom, and a pressurizing device 14 provided at the lower part of the barrel body 11 to pressurize the barrel body 11;

[0055] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com