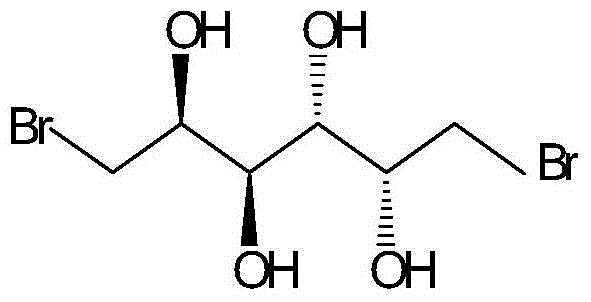

Synthetic method of brominated alkylating agent

A synthesis method and an alkylating agent technology, applied in the field of chemical medicine, can solve the problems of low crystallization purity and unstable yield of dibromodunglitol, and achieve the effects of safe and reasonable process, easy acquisition, difficult cleaning and filtration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

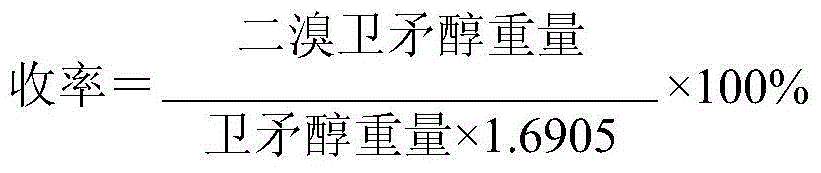

Method used

Image

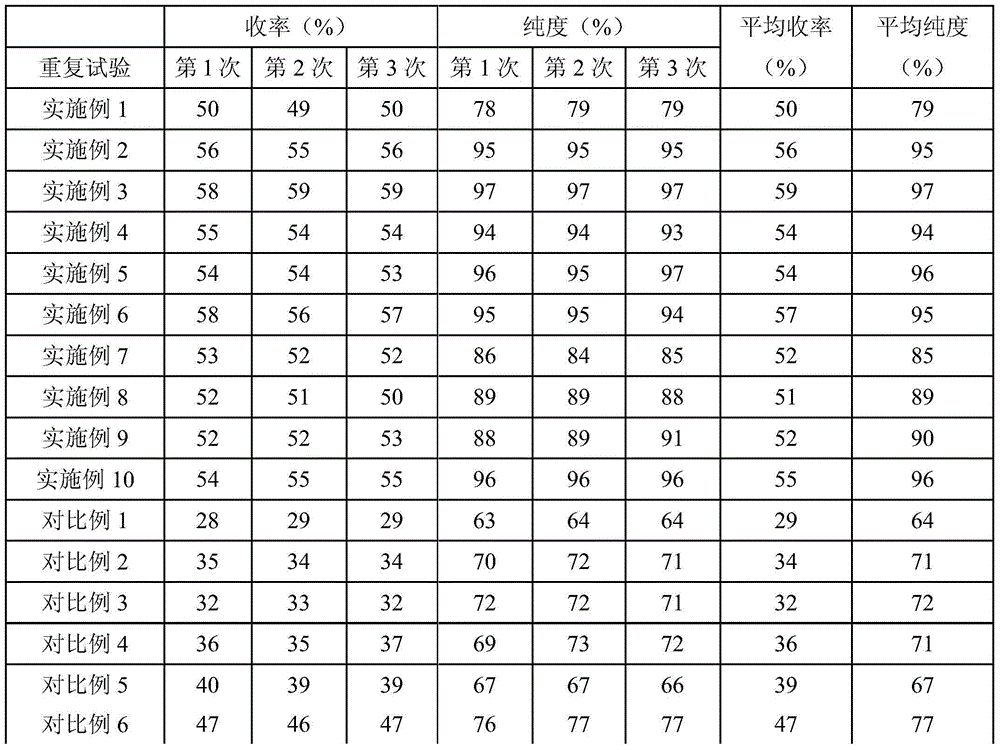

Examples

Embodiment 1

[0067] (a) 10kg dulcitol is dropped into the reactor, add 40% hydrobromic acid aqueous solution: the mixed solution of formic acid=1:2 (weight ratio), add-on is 20 times of dulcitol weight;

[0068] (b) Heating to 65°C in a water bath and stirring continuously until crystallization occurs;

[0069] (c) In a closed state, under constant stirring at 65°C, add formic acid that is 5 times the weight of dulcitol, pressurize to 0.001MPa with nitrogen, continue to react for 2 hours, let cool to room temperature, and let stand for 5 hours;

[0070] (d) Dilute the reaction solution with 1 times the amount of water, filter, wash the filter cake with water until neutral, drain it, add 0.5 times the volume percentage of ethanol with a concentration of 60%, soak it for 0.1 hour, drain it, and reduce the pressure at 25°C to -0.01 Dry at mPa to obtain crude crystals of dibromodulcitol; add methanol 100 times the weight of the crude crystals to the crude crystals of dibromodulcitol, and recry...

Embodiment 2

[0073] (a) 10kg dulcitol is dropped into the reactor, add 45% hydrobromic acid aqueous solution: the mixed solution of acetic acid=1:0.001 (weight ratio), add-on is 5 times of dulcitol weight;

[0074] (b) Heating to 40°C in a water bath and stirring continuously until crystallization occurs;

[0075] (c) In a closed state, under constant stirring at 40°C, add acetic acid 20 times the weight of dulcitol, pressurize to 0.01MPa with argon, continue to react for 12 hours, let cool to room temperature, and let stand for 8 hours;

[0076] (d) Dilute the reaction solution with 2 times the amount of water, filter, wash the filter cake with water until neutral, drain it, add 1 times the volume percentage concentration of 50% ethanol to soak for 0.2 hours, drain it, and reduce the pressure to -0.02 at 30 ° C. Dry at mPa to obtain crude crystals of dibromodulcitol; add methanol 70 times the weight of the crude crystals to the crude crystals of dibromodulcitol, and recrystallize at 6°C t...

Embodiment 3

[0079] (a) 10kg dulcitol is dropped into the reactor, add 50% hydrobromic acid aqueous solution: the mixed solution of acetic acid=1:0.01 (weight ratio), add-on is 10 times of dulcitol weight;

[0080] (b) Heating to 50°C in a water bath and stirring continuously until crystallization occurs;

[0081] (c) In an airtight state and kept at 50°C under constant stirring, add acetic acid containing 33% hydrogen bromide 1 times the weight of dulcitol, feed helium to pressurize to 0.1MPa, continue to react for 18 hours, let cool to room temperature, let stand for 8 hours;

[0082] (d) Dilute the reaction solution with 3 times the amount of water, filter, wash the filter cake with water until neutral, drain it, add 5 times the volume percentage concentration of 65% ethanol to soak for 0.5 hours, drain it, and reduce the pressure at 50 ° C to -0.05 Dry at mPa to obtain crude crystals of dibromodulcitol; add methanol 80 times the weight of the crude crystals to the crude crystals of di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com