Copper-clad laminate

A copper-clad layer and laminated board technology, which is applied in the field of copper-clad laminated boards, can solve problems such as the deterioration of dry film resist adhesion, and achieve a smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

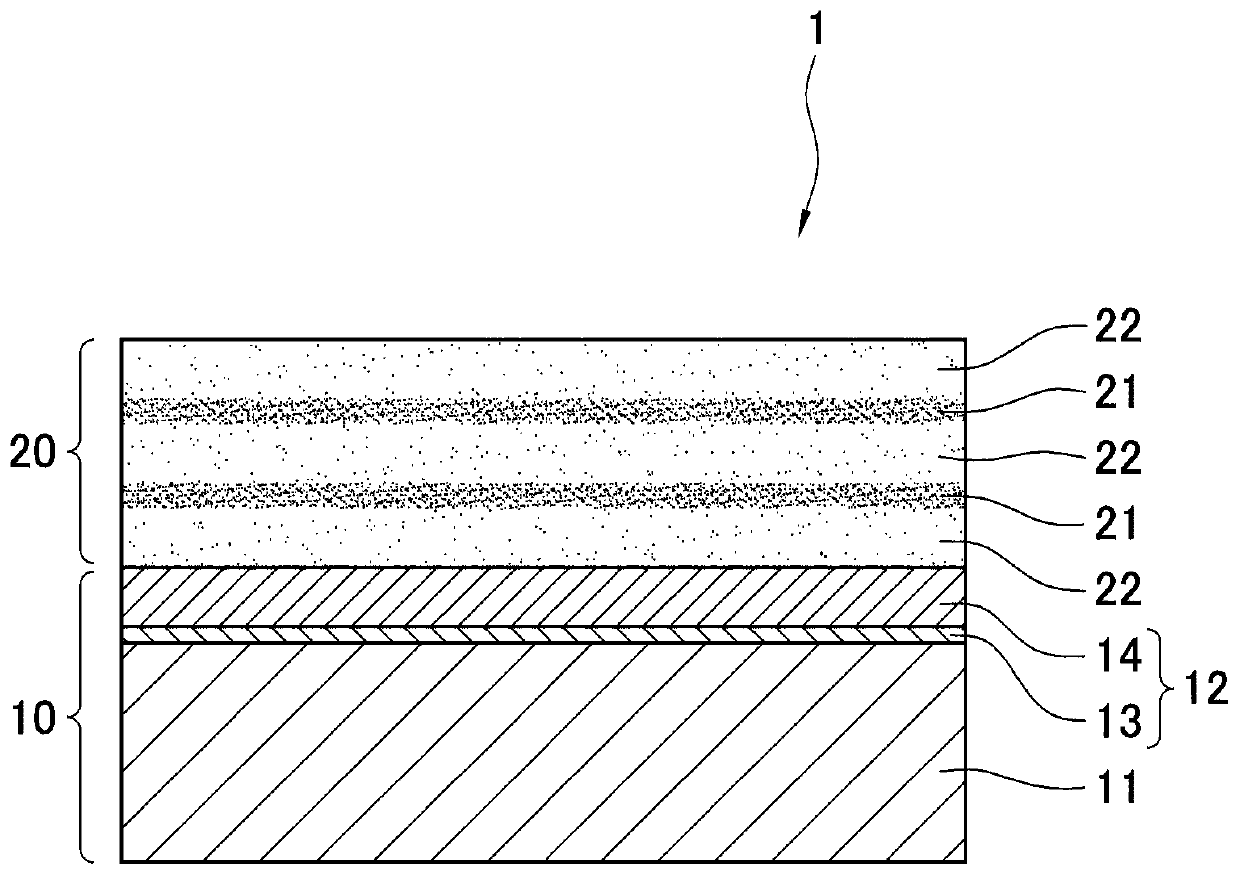

[0060] Follow the steps below to prepare the substrate. As a base film, a polyimide film (manufactured by Ube Industries, Ltd., Upilex-35SGAV1) having a thickness of 35 μm was prepared. Place the base film in a magnetron sputtering device. A nickel-chromium alloy target and a copper target are set in a magnetron sputtering device. The composition of the nickel-chromium alloy target was 20% by mass of Cr and 80% by mass of Ni. In a vacuum environment, a base metal layer made of nickel-chromium alloy with a thickness of 25 nm was formed on one surface of the base film, and a copper thin film layer with a thickness of 100 nm was formed thereon.

[0061] Next, a copper plating solution was prepared. The copper plating solution contains 120g / L copper sulfate, 70g / L sulfuric acid, 20mg / L leveler component, 1100mg / L polymer component, 16mg / L brightener component, and 50mg / L chlorine component. As a leveler component, a diallyldimethylammonium chloride-sulfur dioxide copolymer (ma...

Embodiment 2

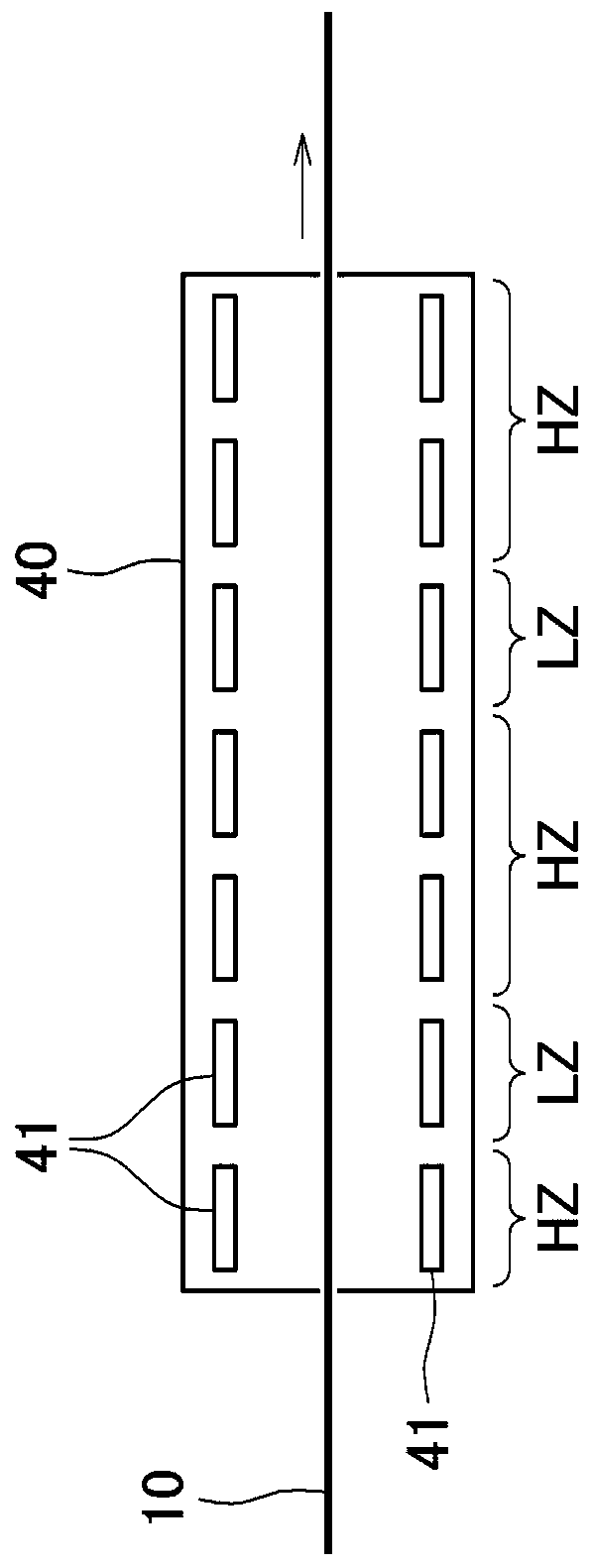

[0065] A copper-clad laminate was obtained in the same manner as in Example 1. However, in the electrolytic plating, the current density was changed so as to include seven jump periods. Other conditions are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com