Plastic liquid coloring agent and preparation technology thereof

A preparation process and colorant technology, applied in the direction of organic dyes, etc., can solve the problems of waste of raw materials, low versatility of color masterbatch, high production cost, reduce toner spots and spots, save space and labor, and reduce raw material loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1-2

[0067] In the experiments in Table 4 below, five different embodiments of the present invention were prepared by using a laboratory-scale multifunctional agitated grinder through dispersive grinding. Various resins are used in injection molding experiments, mainly in injection molding machines. ABS is injection molded at about 230°C-250°C, PC is injection molded at about 280°C-300°C, PET is injection molded at about 260°C-280°C, PP is about 180°C- Injection molding is performed at a temperature of 220°C, and PE is blown at about 200°C. In all the embodiments, the color distribution is balanced, the surface gloss and fullness are high, and there is no toner point in the finished product, and the color is bright and stable. Table 4: The components in the table are weight ratios

[0068]

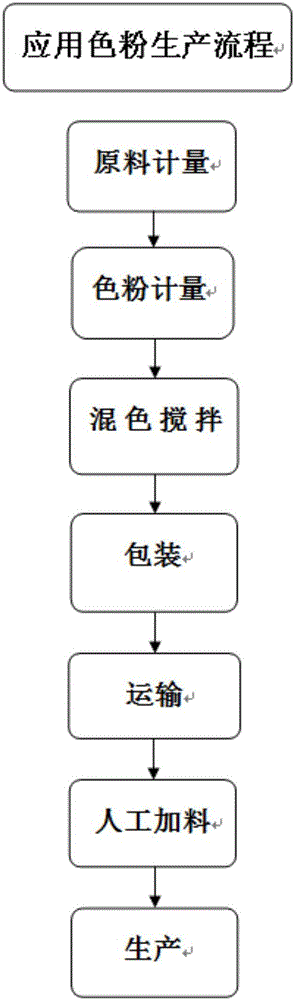

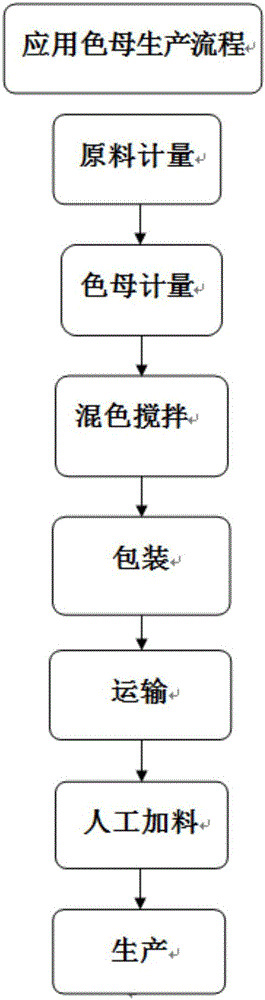

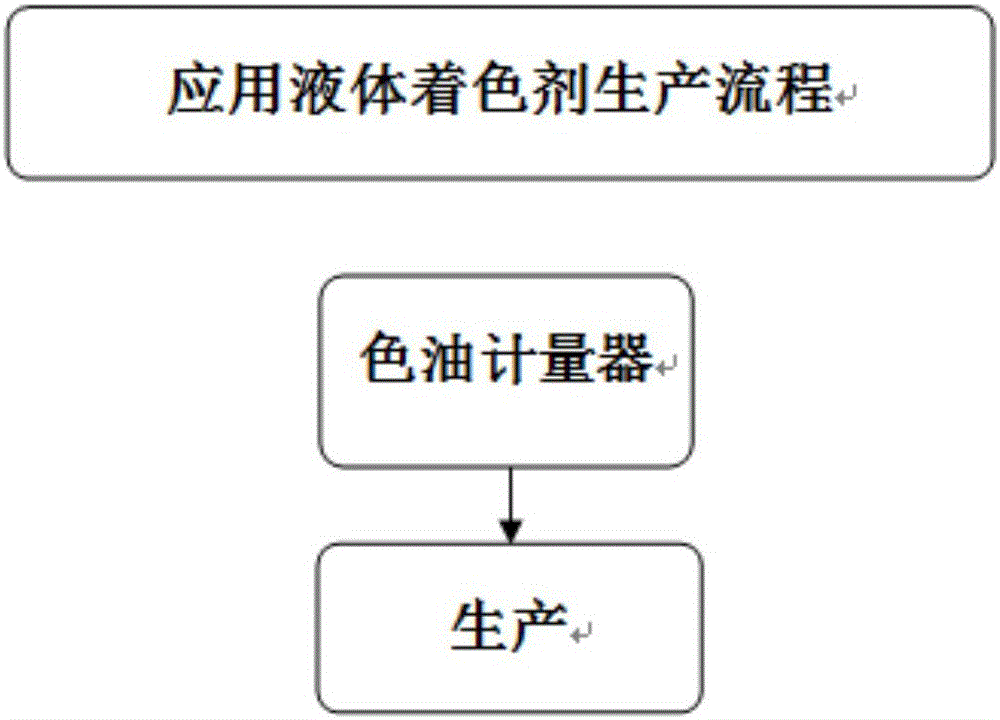

[0069] It can be seen from Table 4 that the use of the liquid color masterbatch of the present invention can significantly improve the performance of plastics. refer to figure 1 , figu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com