Silicon resin environment-friendly waterborne high temperature-resistant coating material as well as preparation and application thereof

A technology of high temperature resistant coatings and silicone resins, applied in fire-resistant coatings, coatings, etc., can solve the problems of easy gelation of the reaction system, accelerated spontaneous condensation reaction, etc., and achieve the effects of good water resistance, good comprehensive performance and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

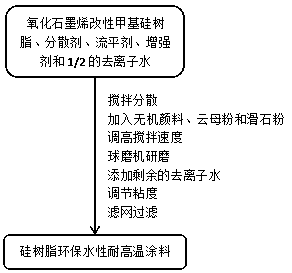

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 Preparation of silicone resin environmental protection water-based high temperature resistant coating

[0031] Raw material composition:

[0032] 55 parts of graphene oxide modified methyl silicone resin, 20 parts of mica powder, 20 parts of talc powder, 1 part of copper stearate, 1 part of polydimethylsiloxane, 0.01 part of polyvinylamine, 0.1 part of iron oxide yellow and 250 parts of deionized water;

[0033] Preparation of graphene oxide modified methyl silicone resin:

[0034] Raw material composition: 30 parts of graphene, 80 parts of methyltrimethoxysilane, 10 parts of alumina, 5 parts of silane coupling agent, 40 parts of absolute ethanol, and 100 parts of deionized water.

[0035] Preparation:

[0036] Step 1, preparation of graphene oxide: adopt improved Hummers method to prepare graphene oxide;

[0037] Step 2. Preparation of graphene oxide-modified methyl silicone resin: Weigh methyltrimethoxysilane and absolute ethanol according to the form...

Embodiment 2

[0040] Embodiment 2 Preparation of silicone resin environmental protection water-based high temperature resistant coating

[0041] Raw material composition:

[0042] 75 parts of graphene oxide modified methyl silicone resin, 35 parts of mica powder, 40 parts of talc powder, 40010 parts of polyethylene glycol, 5 parts of alkyl modified organosiloxane, 3-chloro-2-hydroxypropyl tris 3 parts of methyl ammonium chloride, 5 parts of lithopone and 270 parts of deionized water.

[0043] Preparation of graphene oxide modified methyl silicone resin:

[0044]Raw material composition: 40 parts of graphene, 120 parts of methyltrimethoxysilane, 15 parts of alumina, 15 parts of silane coupling agent, 60 parts of absolute ethanol, and 150 parts of deionized water.

[0045] Preparation:

[0046] Step 1, preparation of graphene oxide: adopt improved Hummers method to prepare graphene oxide;

[0047] Step 2. Preparation of graphene oxide-modified methyl silicone resin: Weigh methyltrimethoxy...

Embodiment 3

[0050] Example 3 Preparation of silicone resin environmental protection water-based high temperature resistant coating

[0051] Raw material composition:

[0052] 65 parts of graphene oxide modified methyl silicone resin, 27 parts of mica powder, 30 parts of talc powder, 5 parts of liquid paraffin, 2 parts of polyether polyester modified organosiloxane, 0.5 parts of nano titanium carbide, 1 part of iron blue , 1 part of cadmium red and 260 parts of deionized water.

[0053] Preparation of graphene oxide modified methyl silicone resin:

[0054] Raw material composition: 35 parts of graphene, 100 parts of methyltrimethoxysilane, 12 parts of alumina, 7 parts of silane coupling agent, 50 parts of absolute ethanol, 120 parts of deionized water;

[0055] Preparation:

[0056] Step 1, preparation of graphene oxide: adopt improved Hummers method to prepare graphene oxide;

[0057] Step 2. Preparation of graphene oxide-modified methyl silicone resin: Weigh methyltrimethoxysilane an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com