Support arm and excavator

A swing frame and connecting arm technology, which is applied in the field of swing frames and excavators, can solve the problems of shaft sleeve detachment, fracture, low overall strength and bonding strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

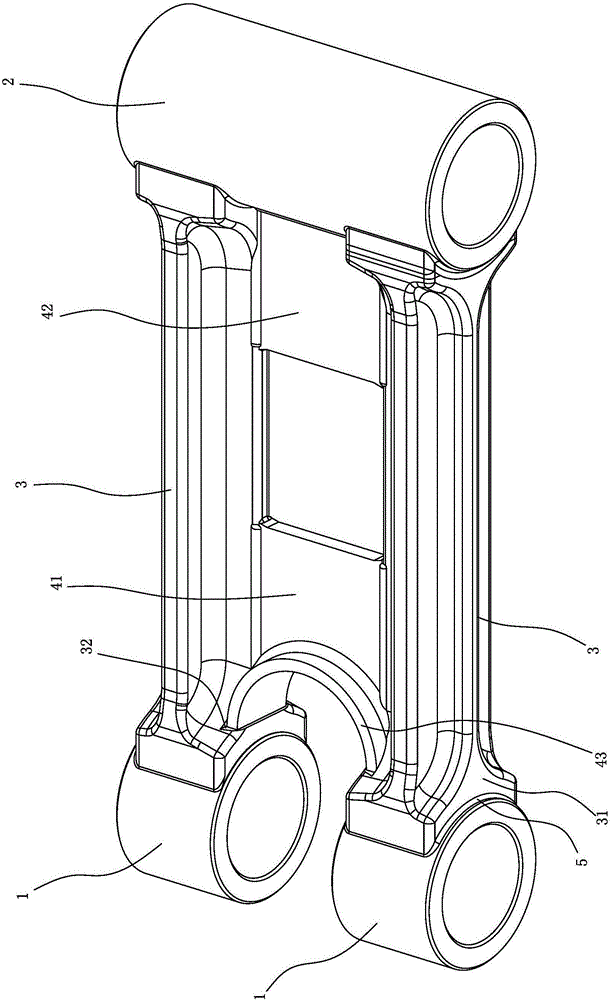

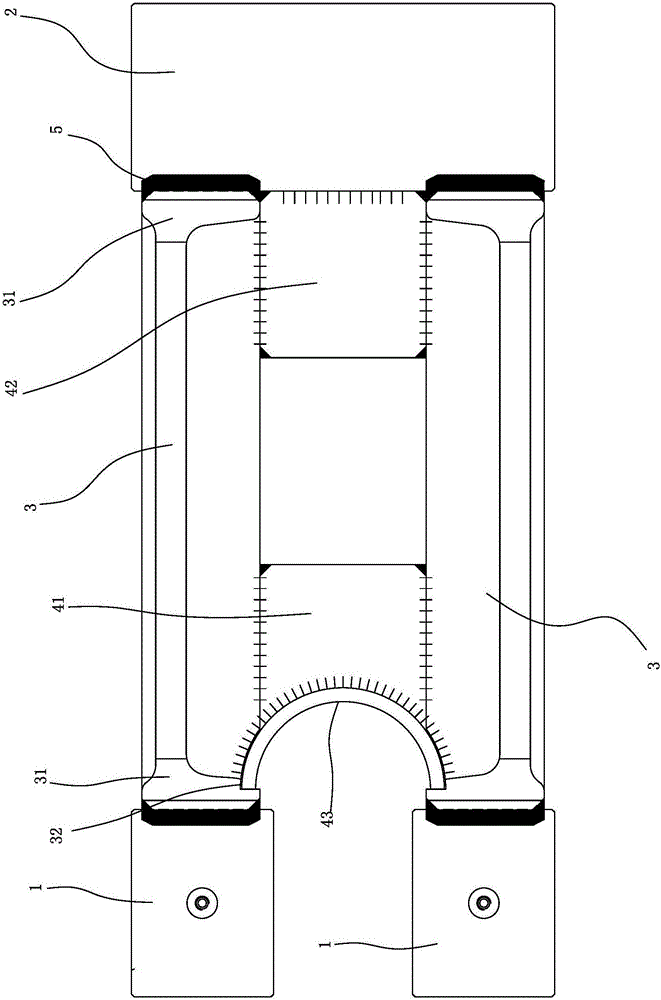

[0024] Embodiment one, with reference to figure 1 , figure 2 , Figure 4 and Figure 5 As shown, a swing frame includes two front bushings 1, a rear bushing 2, two connecting arms 3 and a support.

[0025] The two front bushings 1 are coaxially arranged at intervals, the rear bushing 2 is arranged parallel to the two front bushings 1, and the two connecting arms 3 are respectively welded between the two front bushings 1 and the rear bushing 2, and the supporting parts are welded between the two connecting arms. between arms 3.

[0026] The connecting arm 3 is a forging, and the two ends of the connecting arm 3 are formed with a joint portion 31 that increases and expands. The edge of joint surface 312 forms chamfer 311, and this chamfer 311 and front and rear end bushing 1,2 outer peripheral surfaces form solder filling groove, realizes connecting arm 3 and front and back through the solder 5 that fills in solder filling groove. Welding of end sleeves 1 and 2,

[0027] ...

Embodiment 2

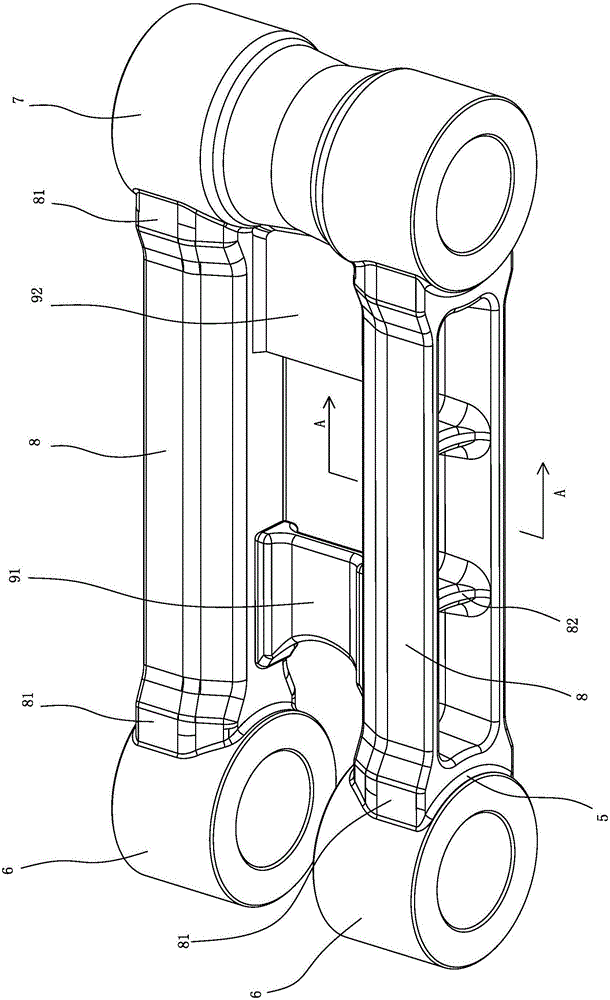

[0029] Embodiment two, refer to image 3 and Figure 6 As shown, a swing frame includes two front bushings 6, rear bushings 7, two connecting arms 8 and support members, the two front bushings 6 are coaxially spaced apart, and the rear bushings 7 are parallel to the two front bushings 6. Arrangement, the two connecting arms 8 are respectively welded between the two front bushings 6 and the rear bushing 7, and the support member is welded between the two connecting arms 8.

[0030] The connecting arm 8 is a forging, and the two ends of the connecting arm 8 are formed with a joint portion 81 that increases and expands. The edge of the surface forms a chamfer 811, and the chamfer 811 and the outer peripheral surfaces of the front and rear end shaft sleeves 6, 7 form a solder filling groove, and the connecting arm 8 and the front and rear end shafts are realized by filling the solder 5 in the solder filling groove. Welding of sets 6 and 7,

[0031] The support includes front an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com