Construction method of compound formwork for special-shaped hyperboloid wood-grain fair-faced concrete wall

A technology of fair-faced concrete and construction methods, which is applied to the preparation of formwork/formwork/work frames, building components on site, and construction. It can solve problems such as inaccurate geometric dimensions, unclear wood grains, and pitted surfaces, and achieve savings Resources, clear lines, smooth walls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

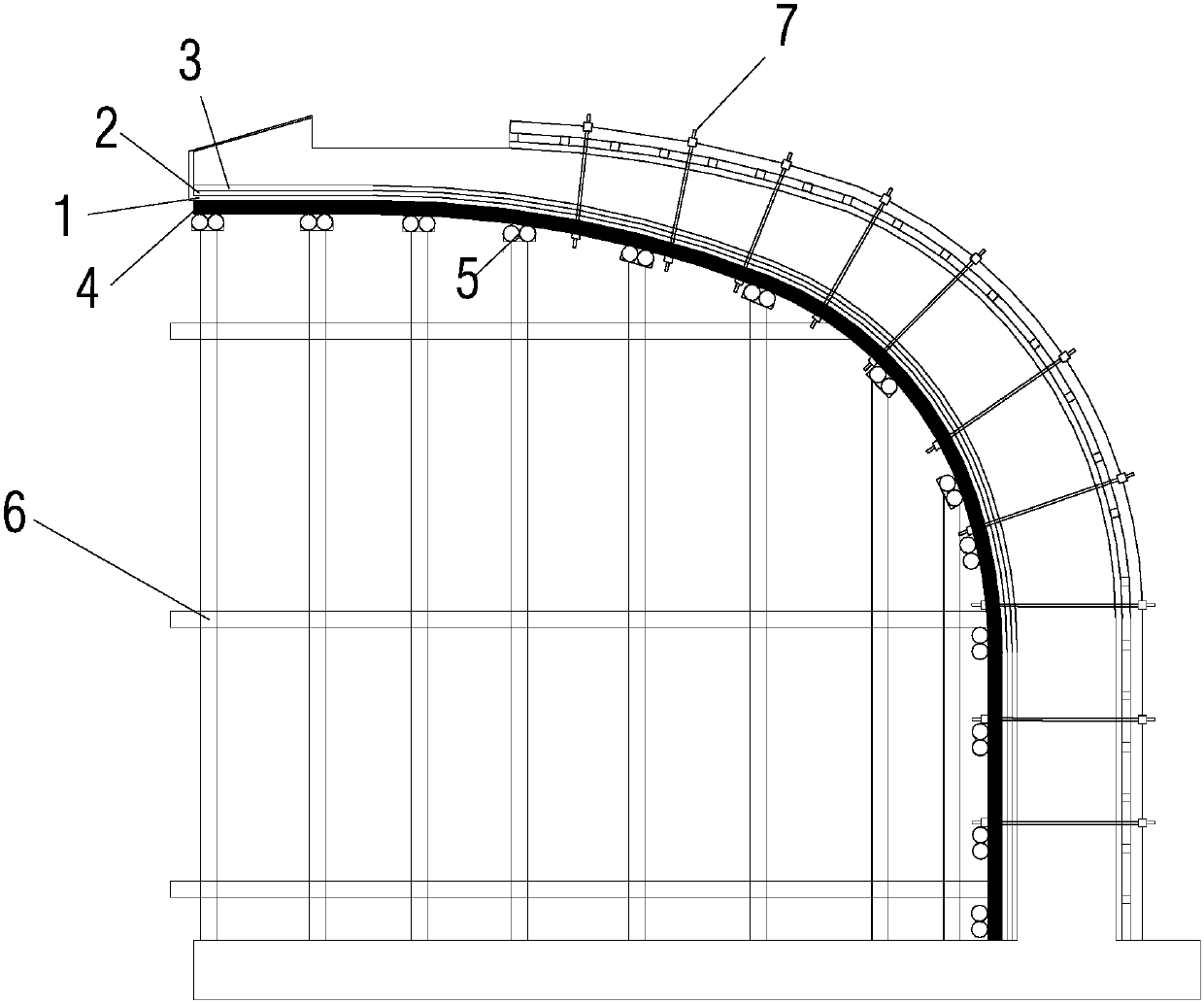

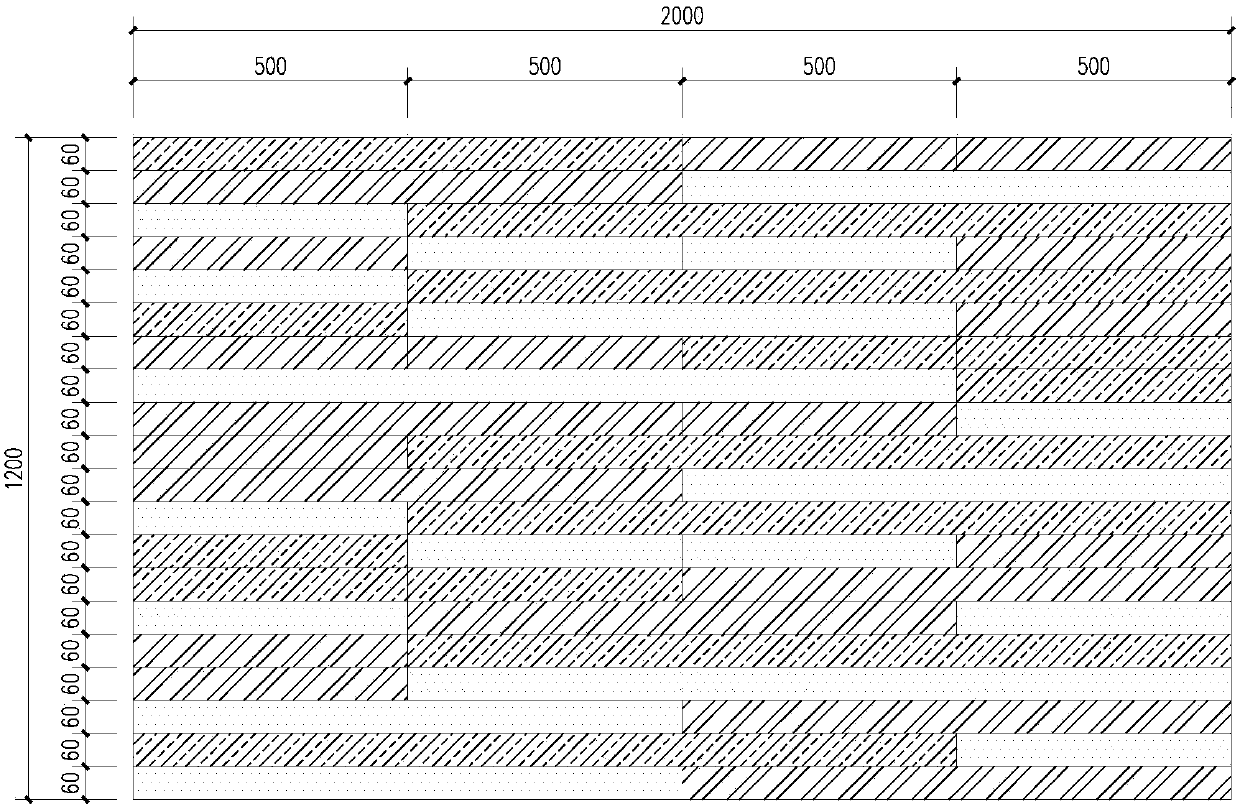

[0026] Such as figure 2 As shown, the special-shaped hyperboloid wood-grain fair-faced concrete wall composite template of the present invention is composed of a template system and a template skeleton; the template system is composed of three layers of curved surface templates superimposed on a backboard 1, a lining board 2 and a panel 3; the template skeleton is composed of vertical corrugations 4 Composed of horizontal flute 5, the formwork skeleton is connected to the formwork system through tension bolts; vertical flute 4 is spliced into an arc-shaped keel by two layers of 12mm thick nine-plywood, and horizontal flute 5 is made of arc-shaped steel pipes, which are connected by jacking brackets and right-angle fasteners and buckl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com