Device for improving internal flow stability of diagonal flow pump

A technology of internal flow and stability, applied to parts, pumps, pump components, etc. of pumping devices used for elastic fluids, can solve the problem of affecting the safety and reliability of the operation of inclined flow pumps, reducing the blade's ability to work on the fluid, and stalling And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

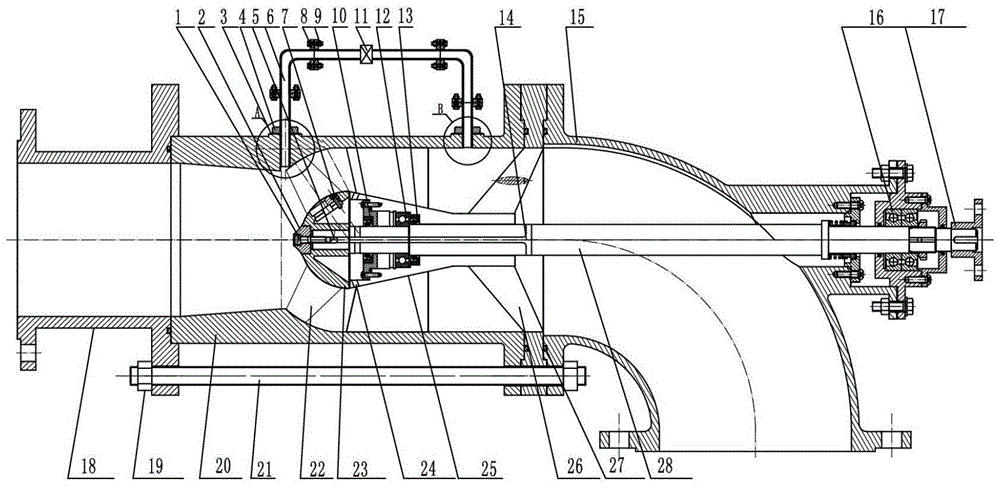

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

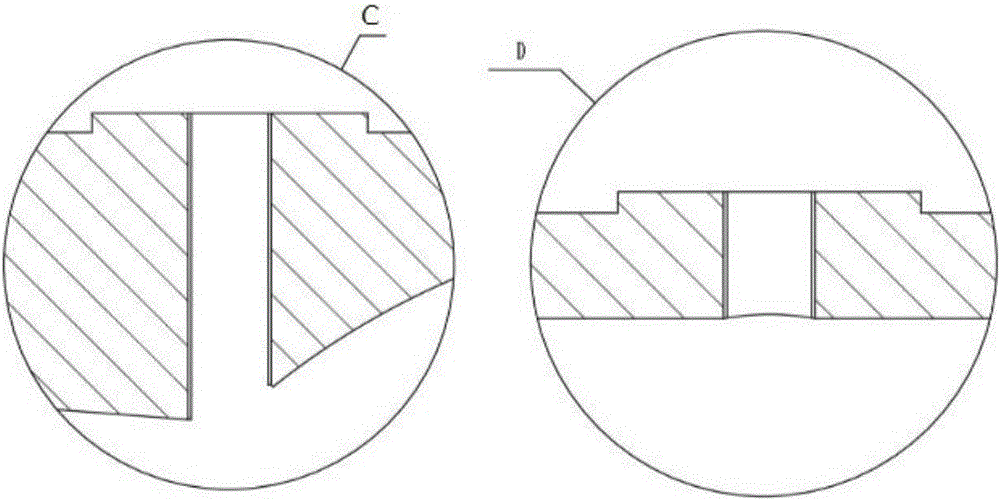

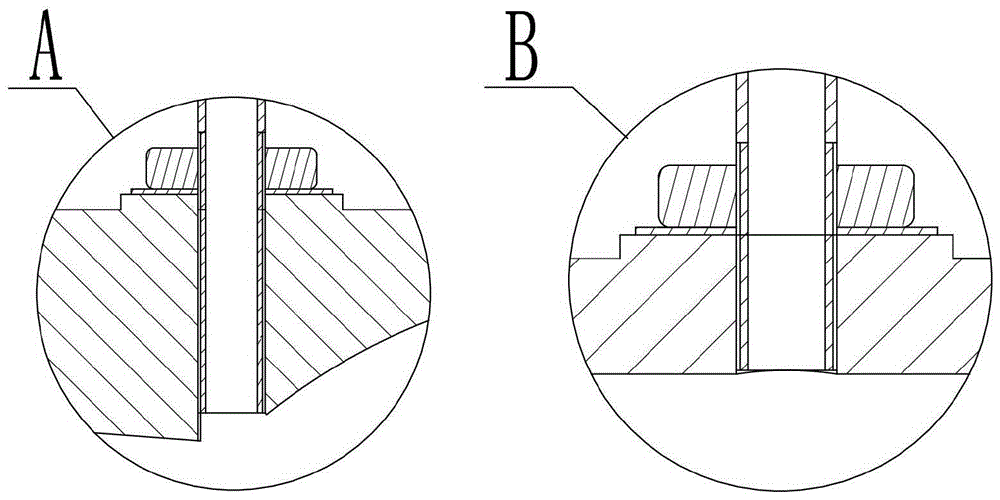

[0029] Depend on figure 1 It can be seen that the diagonal flow pump is composed of (1) hexagon socket head screw, (2) water guide cone, (3) sealing washer, (4) nut, (5) ordinary flat key, (6) conduit (7) cylinder head Screw, (8) flange, (9) bolt, (10) left oil seal of bearing, (11) valve, (12) bearing, (13) right oil seal of bearing, (14) hole, (15) elbow section, ( 16) Rear sealing end cover, (17) Coupling, (18) Inlet section, (19) Hexagonal thick nut, (20) Circular outer cylinder, (21) Pull rod, (22) Blade, (23) Runner Wheel hub, (24) hole, (25) guide vane body, (26) streamlined rib, (27) O-ring, (28) pump shaft. The inlet section (18) is connected and fixed with the circular outer cylinder (20) through the tie rod (21), and the inlet section (18) and the circular outer cylinder (20) are positioned and ensure concentricity throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com