Garbage environmental protection and high efficiency pyrolysis device

A waste, high-efficiency technology, applied in the field of waste environmental protection and high-efficiency pyrolysis device, can solve the problems of high waste incineration cost, increase one-time investment and operation cost, and occupy a long period of capital, and achieve the effect of preventing dioxin-like substances.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

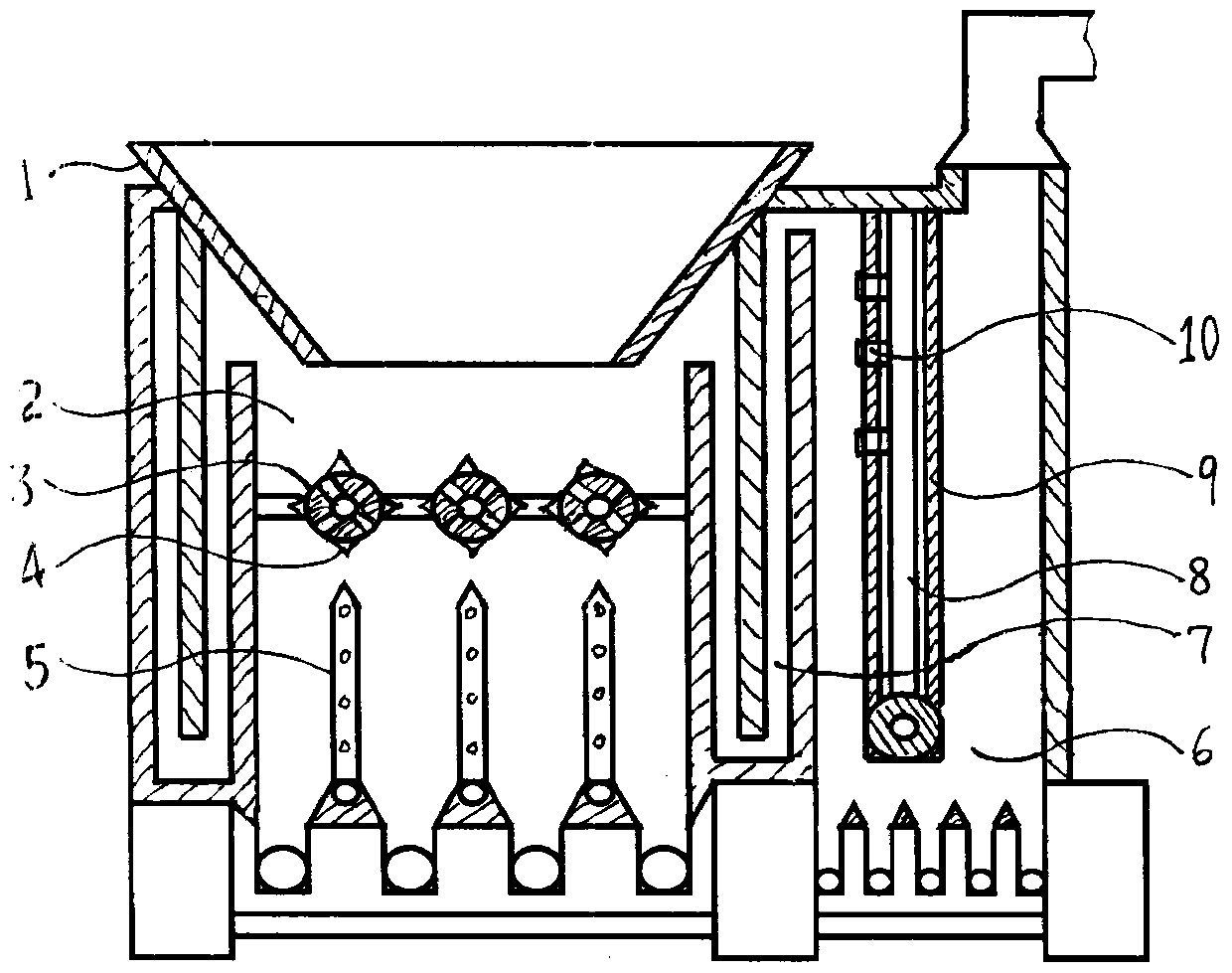

[0029] As shown in the drawing, the garbage environmental protection and high-efficiency pyrolysis device of the present invention includes a garbage input mechanism 1 with a garbage inlet, and the garbage input mechanism communicates with the primary pyrolysis chamber 2, and the primary pyrolysis chamber 2 passes through the curved flue gas channel 7 Connected with the secondary pyrolysis chamber 6, the primary pyrolysis chamber 2 is provided with a primary pyrolysis air conveying mechanism, and the primary pyrolysis air conveying mechanism has a number of horizontal hot air pipes 3 arranged at intervals and vertical hot air pipes 5 below them , the horizontally placed hot air pipe 3 forms a rotatable connection with the power mechanism, the horizontally placed hot air pipe 3 is provided with convex spines 4, and the secondary pyrolysis chamber 6 is provided with a secondary pyrolysis air conveying mechanism, and the secondary pyrolysis air conveying mechanism has several The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com