Efficient recrystallization method of tetraacetylethylenediamine

A technology of tetraacetylethylenediamine and recrystallization, which is applied in the separation/purification of carboxylic acid amides, organic chemistry and other directions, can solve the problems of reducing the yield of TAED, large solvent loss, and high energy consumption, and achieves excellent adsorption capacity and recrystallization. High efficiency, avoids the effect of hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

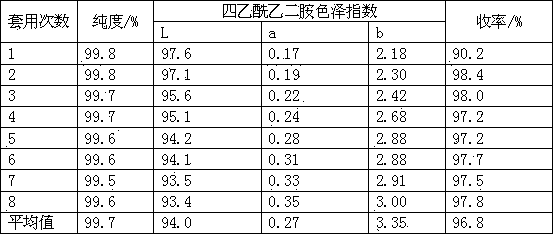

[0017] 700g of tetraacetylethylenediamine, the Lab values are 85.3, 0.38, 8.86 respectively, and the purity is 99.2%. 1000g of acetic acid was used as solvent. Acetic anhydride is used as a hydrolysis inhibitor, and the dosage of acetic anhydride is 50g, which is equivalent to 5% of the mass of acetic acid. The mixture of activated carbon and activated clay with a mass ratio of 1:1 is used as a decolorizing agent, and the dosage is 35g, which is equivalent to 5% of the mass of tetraacetylethylenediamine.

[0018] The above-mentioned substances were placed in a container, heated and stirred to a temperature of 80° C., and stirred and adsorbed for 30 minutes. The recrystallization system is filtered hot, the filtrate is cooled to 25°C with heat exchange and stirring, and then the solid and liquid are separated. The separated liquid is used as the mother liquor, and the solid is washed and dried to recrystallize tetraacetylethylenediamine. HLPC is used to detect the purity, ...

Embodiment 2

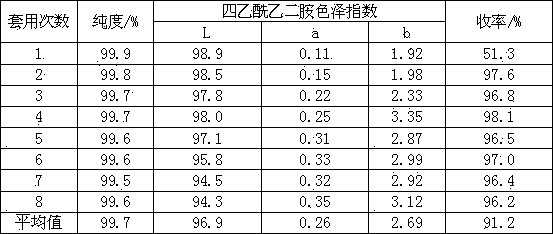

[0023] 500g of tetraacetylethylenediamine, the Lab values are 85.3, 0.38, 8.86 respectively, and the purity is 99.2%; 1000g of acetic acid is used as a solvent; acetic anhydride is used as a hydrolysis inhibitor, and the dosage is 100g, which is equivalent to 10% of the mass of acetic acid. Activated carbon is used as a decolorizing agent in an amount of 50 g, which is equivalent to 10% of the quality of tetraacetylethylenediamine. The above-mentioned substances were placed in a container, heated and stirred to a temperature of 90° C., and stirred and adsorbed for 120 minutes. The recrystallization system is filtered hot, the filtrate is cooled to 25°C with heat exchange and stirring, and then the solid and liquid are separated. The separated liquid is used as the mother liquor, and the solid is washed and dried to recrystallize tetraacetylethylenediamine. HLPC is used to detect the purity, and the Lab mode is used to detect the color.

[0024] Heat the above mother liquor...

Embodiment 3

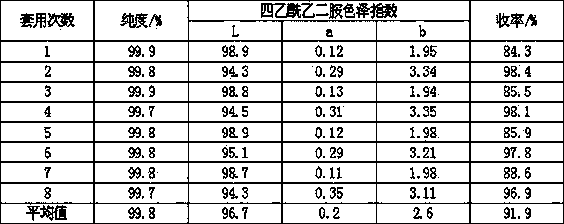

[0028] 100g of tetraacetylethylenediamine, the Lab values are 85.3, 0.38, 8.86, and the purity is 99.2%; 1000g of acetic acid is used as a solvent; acetic anhydride is used as a hydrolysis inhibitor, and the dosage is 1g, which is equivalent to 0.1% of the mass of acetic acid. Activated clay is used as a decolorizing agent in an amount of 0.5 g, which is equivalent to 0.5% of the quality of tetraacetylethylenediamine. The above-mentioned substances were placed in a container, heated and stirred to a temperature of 60° C., and stirred and adsorbed for 5 minutes. The recrystallization system is filtered hot, the filtrate is cooled to 25°C with heat exchange and stirring, and then the solid and liquid are separated. The separated liquid is used as the mother liquor, and the solid is washed and dried to recrystallize tetraacetylethylenediamine. HLPC is used to detect the purity, and the Lab mode is used to detect the color.

[0029] Heat the above mother liquor to 100°C, add 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com