Energy-saving environment-friendly efficient pyrolysis device for garbage

An energy-saving, environment-friendly, waste-free technology, applied in lighting and heating equipment, combustion methods, indirect carbon dioxide emission reduction, etc., can solve the problems of increasing one-time investment and operating costs, high operating costs, and large manufacturing costs, and achieve high-efficiency and high-quality treatment. Waste, low running cost, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

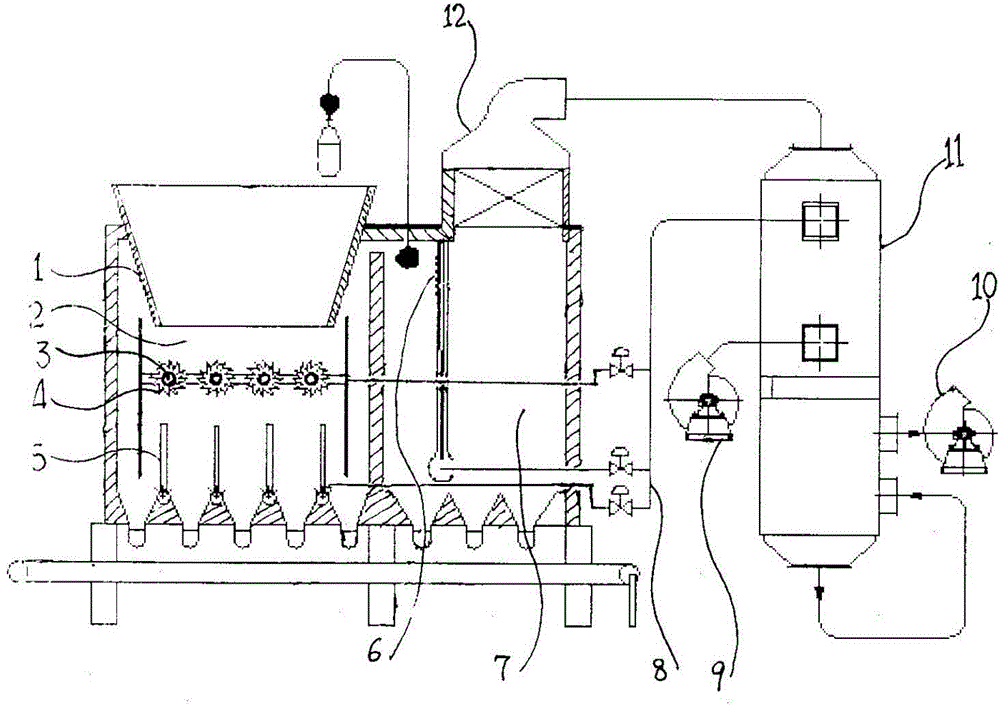

[0022] As shown in the accompanying drawing, the garbage energy-saving, environment-friendly and efficient pyrolysis device of the present invention includes a primary pyrolysis chamber 2 communicated with the garbage input mechanism 1, the primary pyrolysis chamber 2 communicates with the secondary pyrolysis chamber 7 through the flue gas channel, and the secondary pyrolysis chamber 7 communicates with the secondary pyrolysis chamber 7. The decomposition chamber 7 is connected to the flame heat exchange mechanism 11 through the flame gas output mechanism 12, and the flame gas heat exchange mechanism 11 communicates with the primary pyrolysis chamber 2 and the secondary pyrolysis chamber 7 through the hot air delivery mechanism 8 respectively.

[0023] Four horizontal hot air pipes 3 are arranged at intervals in the primary pyrolysis chamber 2, and four vertical hot air pipes 5 are arranged at intervals below the horizontal hot air pipes 3, and the flame heat exchange mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com