Cuttable and wearable stress sensor and preparation method thereof

A strain sensor and strain sensing technology, applied in the field of sensors, can solve problems such as not being able to meet wearable conditions, and achieve rapid large-area preparation, easy operation, and good product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

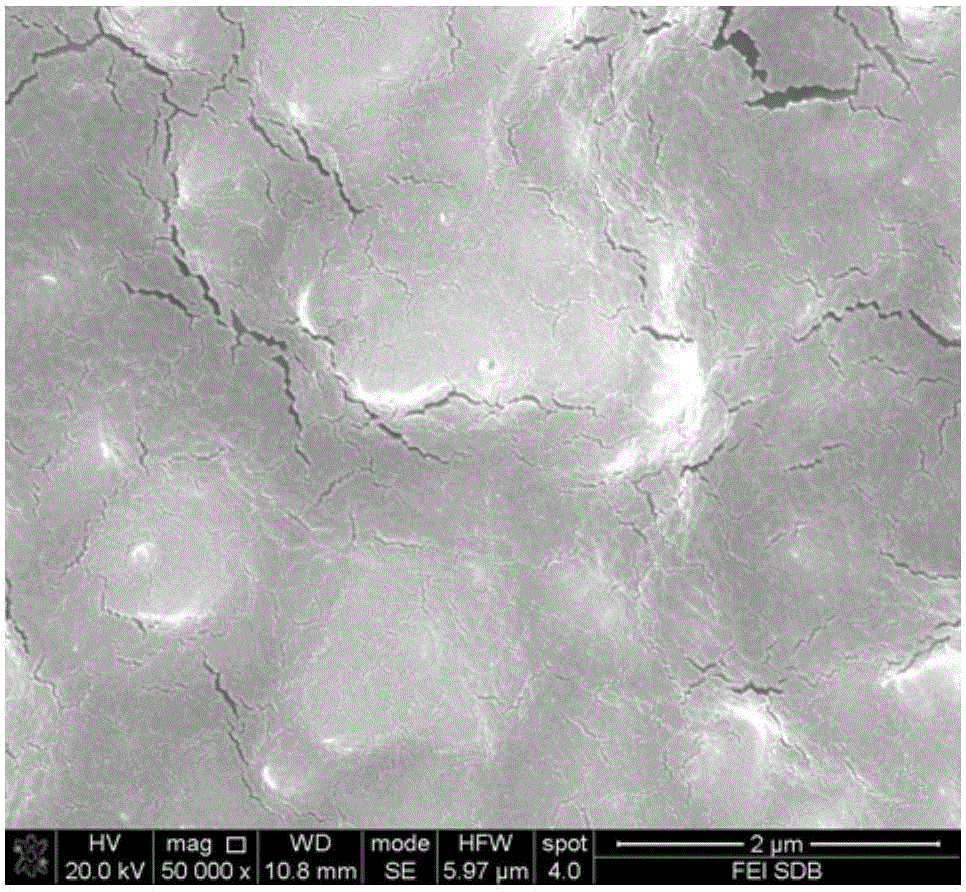

[0027] Step 1: Sputter a 50-nanometer thick gold nanofilm by DC sputtering on the surface of a rectangular sandpaper with a width of 4.0 centimeters and a mesh number of 10,000. The microscopic appearance of the formed gold nanofilm is as follows: figure 1 shown.

[0028] Step 2: Use scissors to cut into a cuttable wearable strain sensor with a length of 5.0 cm and a width of 3.0 cm.

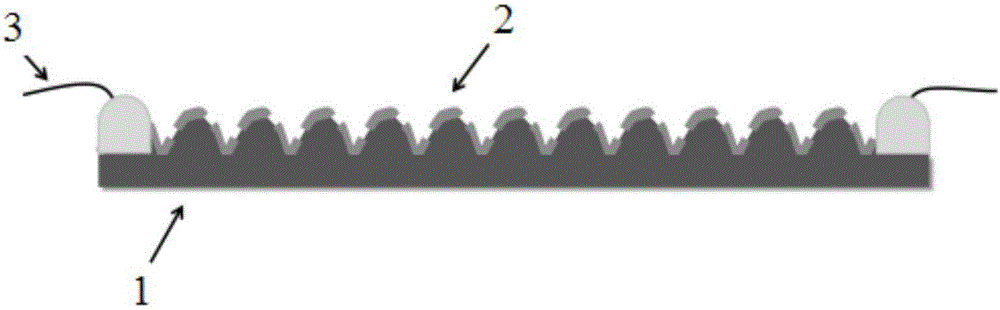

[0029] Step 3: Use silver glue to lead out the wires from both ends of the sandpaper obtained in step 2 along the length direction to obtain a wearable strain sensor that can be cut. The schematic diagram of its structure is as follows figure 2 shown.

[0030] The obtained wearable shearable strain sensor with a length of 5.0 cm and a width of 3.0 cm is fixed on the index finger with double-sided tape, and can be used for finger bending detection, which can meet the 0-10 Hz finger bending monitoring.

Embodiment 2

[0032] Step 1: Sputter a 30 nanometer thick gold nano film by direct current sputtering on the surface of a rectangular sandpaper with a width of 3.0 cm and a width of 1.0 cm and a mesh number of 1500.

[0033] Step 2: Use scissors to cut into a cuttable wearable strain sensor with a length of 3.0 cm and a width of 0.5 cm.

[0034] Step 3: Use silver glue to draw wires from both ends of the sandpaper obtained in step 2 along the length direction to obtain a wearable strain sensor that can be cut.

[0035] The obtained cutable wearable strain sensor with a length of 3.0 cm and a width of 0.5 cm is fixed at the crack of the door with double-sided tape, and can be used to detect the opening and closing angle of the door. The detected opening and closing angle is -179 to Between 179 degrees.

Embodiment 3

[0037] Step 1: Sputter a 45 nm thick gold nano film by magnetron sputtering on the surface of a rectangular sandpaper with a width of 2.0 cm and a width of 0.5 cm and a mesh number of 2000.

[0038] Step 2: Use scissors to cut into a cuttable wearable strain sensor with a length of 2.0 cm and a width of 0.25 cm.

[0039] Step 3: Use silver glue to draw wires from both ends of the sandpaper obtained in step 2 along the length direction to obtain a wearable strain sensor that can be cut.

[0040] The obtained cutable wearable strain sensor with a length of 2.0 cm and a width of 0.25 cm is fixed on the arm skin with double-sided adhesive, and can be used to detect arm muscle activity, which can meet the 0-20 Hz muscle movement monitoring.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com