A method for fabricating superhydrophobic antireflection structures on irregular metal surfaces

An irregular, super-hydrophobic technology, applied in metal processing equipment, welding equipment, manufacturing tools, etc., can solve the problems of complex sample control and inability to prepare large-area samples, achieve uniform strength, and realize the effect of remote rapid large-area preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific implementation examples.

[0030] Concrete implementation steps of the present invention are as follows:

[0031] 1. Build a femtosecond laser filament microstructured device with irregular stainless steel and titanium alloy metal curved sample surfaces.

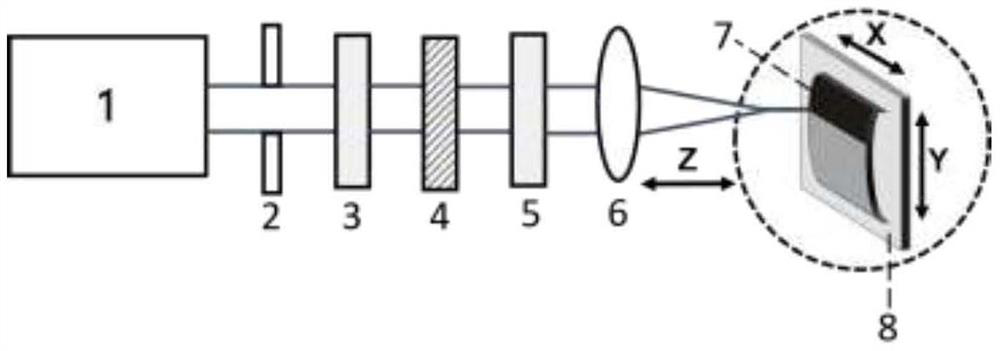

[0032]It is characterized in that it consists of a titanium sapphire femtosecond laser amplification system 1, a precision electronic switch 2, a half-wave plate 3, a polarizer 4, a half-wave plate 5, a focusing lens 6, and irregular stainless steel and titanium alloy metal surface samples 7, The computer-controlled three-dimensional displacement platform 8 is composed of a precision electronic switch 2, a half-wave plate 3, a polarizer 4, a half-wave plate 5, and a focusing lens 6 in the direction of propagation of the laser. By controlling the movement of the three-dimensional displacement platform 8 A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com