A kind of copper-clad or copper-clad aluminum oxide ceramic substrate and preparation method thereof

A technology of alumina ceramics and copper alloys, applied in metal material coating process, coating, melting spray plating, etc., can solve the problems of high cost, difficult production, large equipment investment, etc., and achieve low cost and high utilization rate of raw materials , the effect of excellent coating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

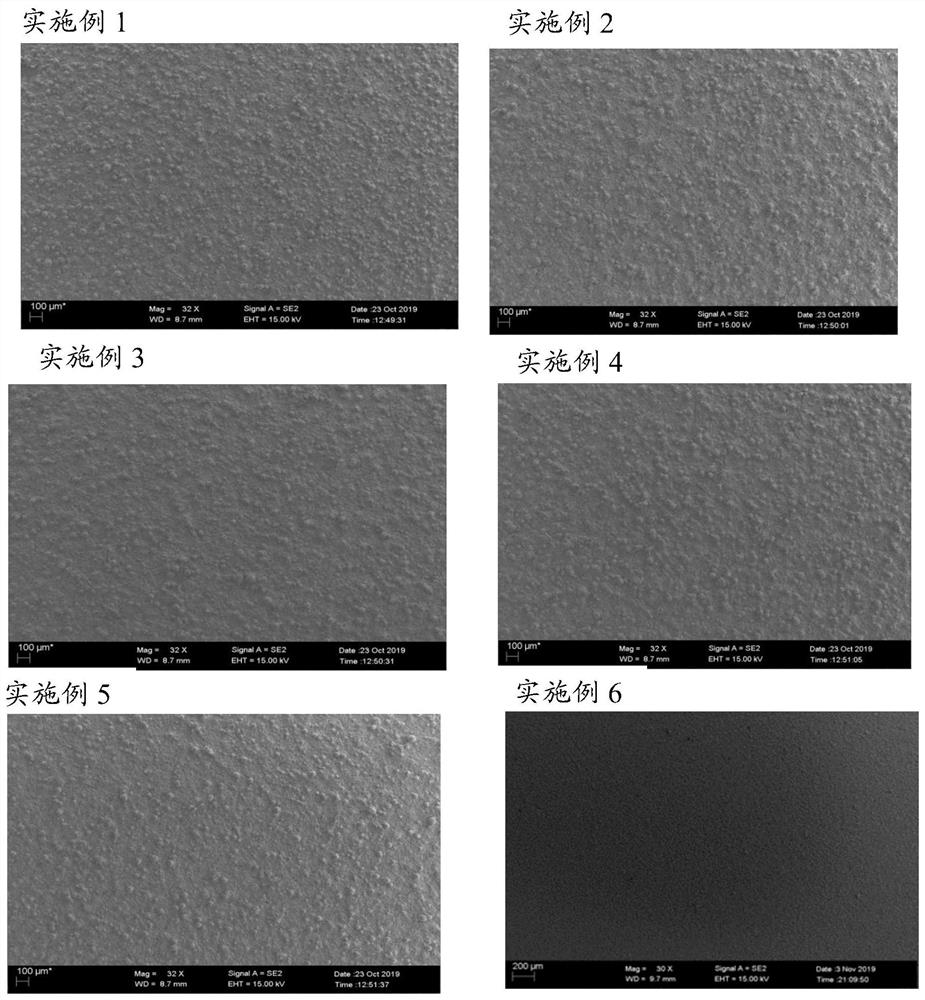

Embodiment 1

[0086] In this embodiment, copper is deposited on the surface of alumina ceramics according to the following steps to prepare an alumina ceramic circuit board.

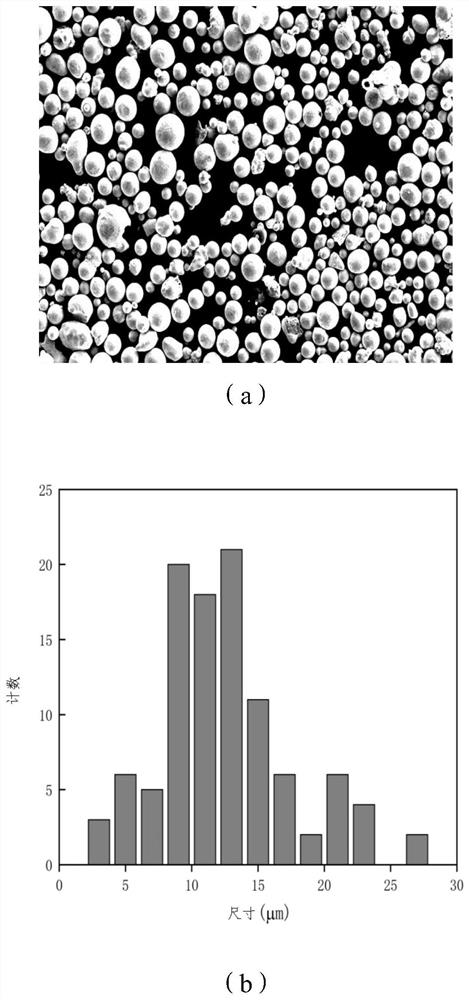

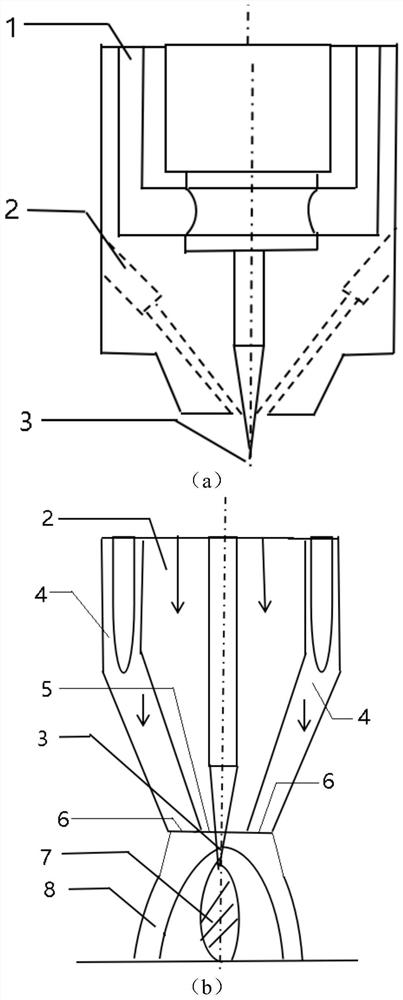

[0087] (1) Add metal copper powder with an average particle size of 30 microns into the atmospheric plasma spraying feeding system, and turn on the argon gas switch. Turn on the main switch, power switch, gas switch, air compressor and vacuum cleaner switch of the spraying equipment in turn, and set the operation program to make the cooling water run. Install specified tungsten electrodes and custom powder plasma torches (eg figure 2 Shown in middle a, cooling air nozzle is not shown), produces plasma beam outside spray gun nozzle;

[0088] (2) Clean the alumina ceramic substrate with a surface roughness of about 3 μm in alcohol and acetone to remove organic matter and impurities on the surface, and then fix it on the workbench;

[0089] (3) The spraying process parameters are set, the spraying start coordinates (X=...

Embodiment 2

[0093] (1) Add metal copper powder with an average particle size of 30 microns into the atmospheric plasma spraying feeding system, and turn on the argon gas switch. Turn on the main switch, power switch, gas switch, air compressor and vacuum cleaner switch of the spraying equipment in turn, and set the operation program to make the cooling water run. Install specified tungsten electrodes and custom powder plasma torches (eg figure 2 As shown in a, the cooling gas nozzle is not shown), and the plasma beam is generated outside the nozzle of the spray gun.

[0094] (2) Clean the alumina ceramic substrate with a surface roughness of about 3 μm in alcohol and acetone to remove organic matter and impurities on the surface, and then fix it on the workbench.

[0095](3) Set the spraying process parameters, the spraying start coordinates (X=0mm, Y=0mm), the end coordinates (X=40mm, Y=40mm), the spraying current is 150A, the distance from the plasma spray gun mouth to the ceramic subs...

Embodiment 3

[0099] (1) Add copper powder with an average particle size of 50 microns into the atmospheric plasma spraying feeding system, and turn on the argon-hydrogen mixture gas switch, and the hydrogen content is 5% by volume. Turn on the main switch, power switch, gas switch, air compressor and vacuum cleaner switch of the spraying equipment in turn, and set the operation program to make the cooling water run. Install specified tungsten electrodes and custom powder plasma torches (eg figure 2 Shown in middle a, cooling air nozzle is not shown), produces plasma beam outside spray gun nozzle;

[0100] (2) Clean the alumina ceramic substrate with a surface roughness of about 3 μm in alcohol and acetone to remove organic matter and impurities on the surface, and then fix it on the workbench.

[0101] (3) Set the spraying process parameters, the spraying start coordinates (X=0mm, Y=0mm), the end coordinates (X=40mm, Y=40mm) the spraying current is 150A, the distance from the plasma spray...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com