A kind of elastic wearable strain sensor and preparation method thereof

A strain sensor and sensor technology, applied in the sensor field, can solve the problems of complex preparation method and long production cycle of the strain sensor, and achieve the effects of rapid large-area preparation, good product performance and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

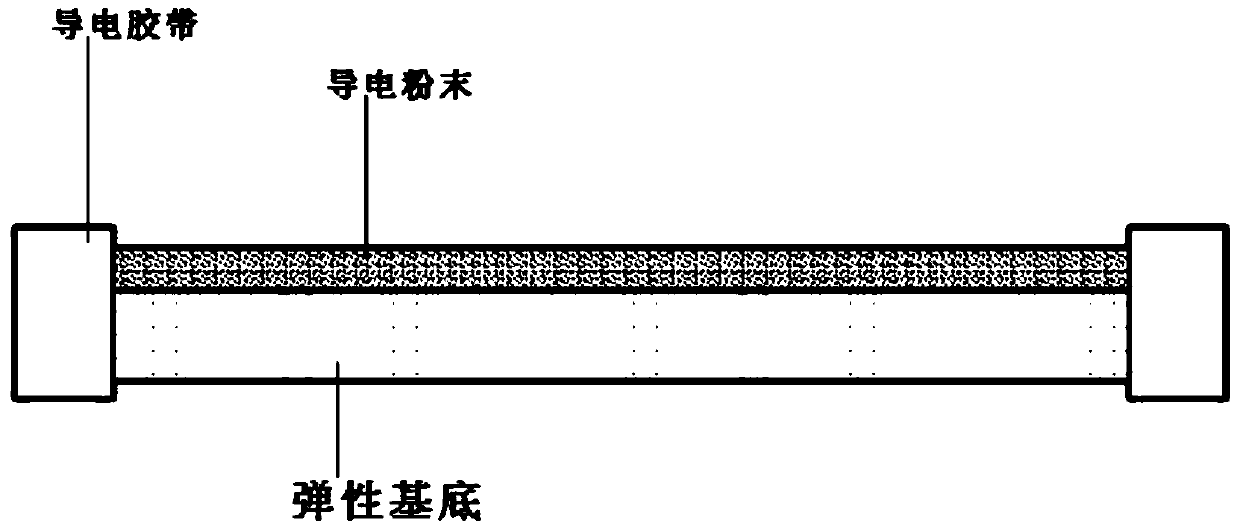

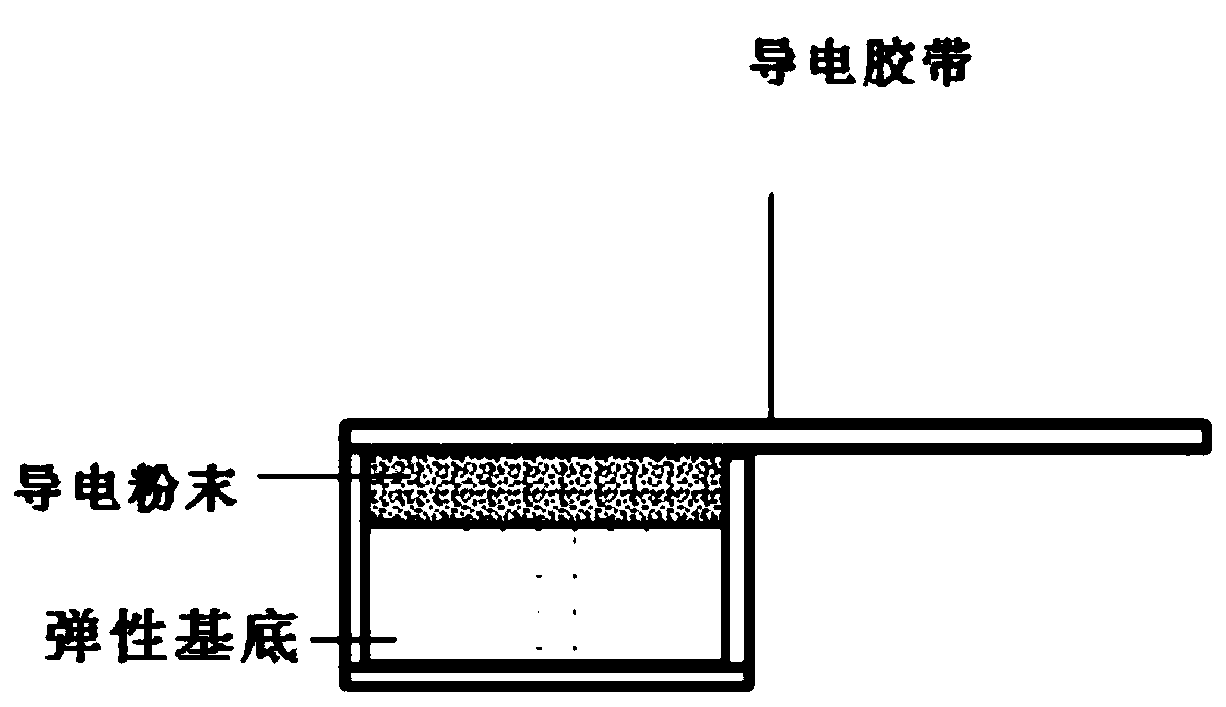

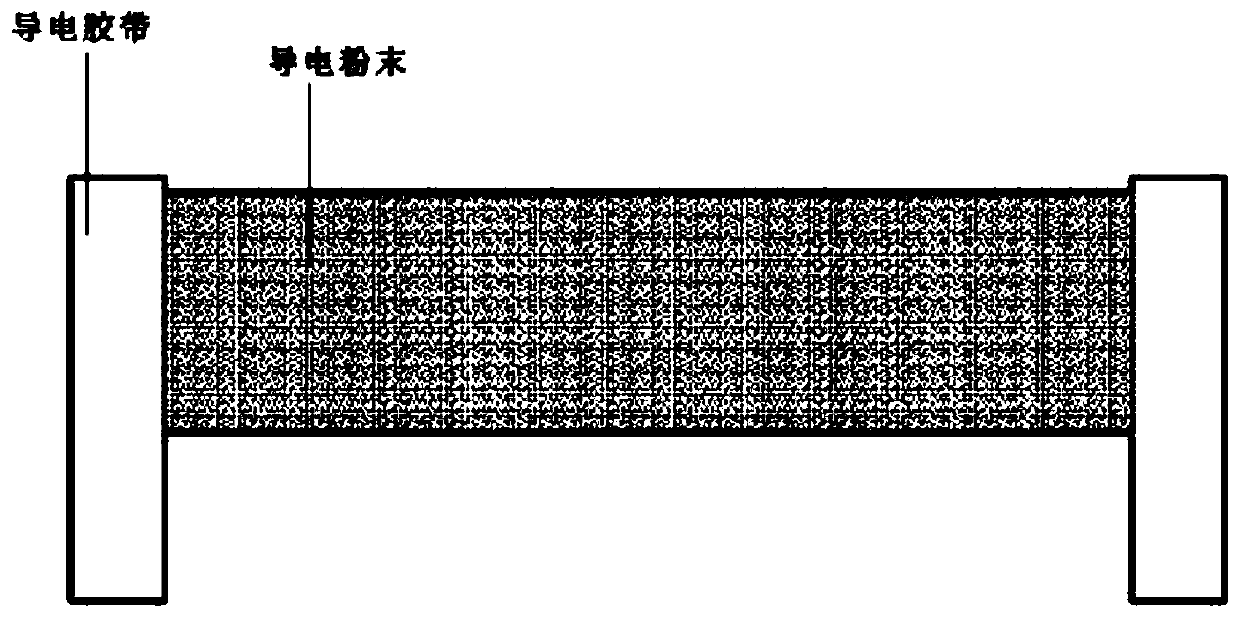

[0037] Such as Figure 1-3 Shown are three views of the sensor of the present invention, the present invention provides a method for preparing an elastic wearable strain sensor, the preparation method comprising:

[0038] Step 1: Coating conductive powder on the surface of the semi-cured elastic substrate;

[0039] Step 2: curing the semi-cured elastic substrate obtained in step 1 with conductive powder attached to its surface;

[0040] Step 3: Lead out the electrodes at both ends of the conductive powder layer through conductive tape to form an elastic wearable strain sensor.

[0041] The step 1 is specifically:

[0042] 1-1) Stir and mix liquid dimethyl siloxane and curing agent at a mass ratio of 8:1-12:1;

[0043] 1-2) Pour 0.5-50 grams of the mixture obtained in 1-1) into a rectangular box with a flat bottom and a width-to-length ratio of 1:1-20:1;

[0044] 1-3) Put the rectangular box containing the mixture obtained in step 1-1) obtained through step 1-2) into an ove...

Embodiment 1

[0054] (1) Stir and mix liquid dimethyl siloxane and curing agent at a mass ratio of 10:1;

[0055] (2) Pour 3 grams of the mixture obtained in step (1) into a rectangular box with a flat bottom surface of 1 cm in width and 5 cm in length;

[0056] (3) Put the rectangular box containing the mixture obtained in step (1) obtained through step (2) into an oven for processing, the processing temperature is 50 degrees Celsius, and the processing time is 50 minutes; after this processing, the incompletely cured polydimethylsiloxane;

[0057] (4) Take out the rectangular box containing incompletely cured polydimethylsiloxane obtained in step (3), add 1 gram of graphite powder to the incompletely cured polydimethylsiloxane obtained in step (3) On the surface of oxane, use a scraper to completely coat the graphite powder on the surface of the incompletely cured polydimethylsiloxane, and recycle the excess graphite powder;

[0058] (5) Put the incompletely cured polydimethylsiloxane s...

Embodiment 2

[0063] (1) Stir and mix liquid dimethylsiloxane and curing agent at a mass ratio of 9:1;

[0064] (2) Pour 3 grams of the mixture obtained in step (1) into a rectangular box with a flat bottom surface of 0.8 cm in width and 7 cm in length;

[0065] (3) Put the rectangular box containing the mixture obtained in step (1) obtained through step (2) into an oven for processing, the processing temperature is 48 degrees Celsius, and the processing time is 60 minutes; after this processing, the incompletely cured polydimethylsiloxane;

[0066] (4) Take out the rectangular box containing incompletely cured polydimethylsiloxane obtained in step (3), add 2 grams of copper powder to the incompletely cured polydimethylsiloxane obtained in step (3) On the surface of oxane, use a scraper to completely coat the copper powder on the surface of the incompletely cured polydimethylsiloxane, and recover the excess silver powder;

[0067] (5) Put the incompletely cured polydimethylsiloxane surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com