Metal-polymer composite material as well as preparation method and application thereof

A technology of polymer materials and composite materials, which is applied in the field of metal-polymer composite materials and their preparation, can solve problems such as time-consuming, high equipment investment costs, and complicated manufacturing processes, so as to improve content and uniformity, meet application requirements, The effect of improving the binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

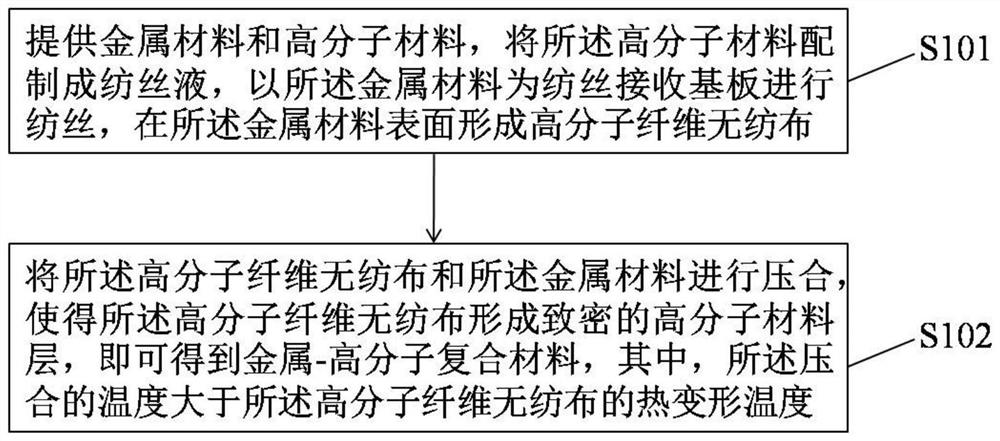

[0059] see figure 1 , a flow chart of a method for preparing a metal-polymer composite material provided by an embodiment of the present invention, including the following steps:

[0060]Step S101: Provide metal materials and polymer materials, prepare the polymer materials into spinning solutions, use the metal materials as spinning receiving substrates for spinning, and form polymer fiber non-woven fabrics on the surface of the metal materials .

[0061] In the embodiment of the present invention, the material of the metal material includes at least one of copper, aluminum, iron, silver, palladium, nickel, chromium, molybdenum, tungsten, zinc, manganese, cobalt, gold, tin, lead and stainless steel. Further, the material of the metal material includes at least one of copper, aluminum, iron, nickel, zinc, manganese, tin, lead and stainless steel.

[0062] In an embodiment of the present invention, the thickness of the metal material is 5 μm-100 μm. Optionally, the thickness...

Embodiment 1

[0096] A kind of preparation method of metal-polymer composite material

[0097] The liquid crystal polymer is poured into the spinning machine, and the temperature is kept at 330° C. to melt and blend to form a spinning solution.

[0098] Copper foil with a thickness of 10 μm is provided, and the surface of the copper foil is roughened and anti-oxidized, and is ready for use.

[0099]Put the treated copper foil on the conveyor belt and directly use it as the receiving substrate for spinning. The spinning solution is melt-blown into a polymer fiber non-woven fabric and attached to the surface of the copper foil to form a polymer fiber non-woven fabric. / metal composite material; spinning parameters are: melt-blown spinning temperature is 300 ° C, hot air temperature is 320 ° C, air pressure is 0.2 MPa, the vertical distance between the receiving substrate and the spinneret is 300 mm, and the injection rate is 20 μl / min, the moving speed of the copper foil conveyor belt is 1...

Embodiment 2

[0102] A kind of preparation method of metal-polymer composite material

[0103] Prepare the spinning solution according to the following mass content ratio:

[0104]

[0105]

[0106] Copper foil with a thickness of 12 μm is provided, and the surface of the copper foil is sanded, cleaned, dried, and plasma treated for later use.

[0107] Place the treated copper foil on the conveyor belt and directly use it as the receiving substrate for spinning. Electrospin the spinning solution through the solution to make a polymer fiber non-woven fabric and attach it to the surface of the copper foil to form a polymer fiber non-woven fabric. / metal composite material; the spinning parameters are: the vertical distance between the receiving substrate and the spinneret is 200mm, the voltage is 20KV, the injection rate is 5μl / min, and the moving speed of the copper foil conveyor belt is 1mm / s.

[0108] After drying the polymer fiber non-woven fabric / metal composite material, it is t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com