Surface Measurement Device Using Laser Rotation Scanning

A technology of rotating scanning and measuring devices, which is applied in the field of laser scanning systems, can solve problems such as high stability and complex structure, and achieve the effects of convenient control, simple control process and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following is a further detailed description of the composition of the laser-based rotary scanning surface measurement device and the surface measurement process of the present invention through various drawings, but the patent protection scope of the present invention is not limited thereto.

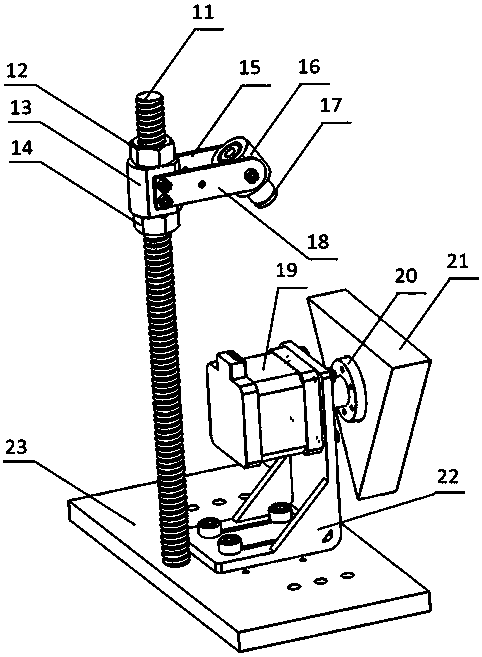

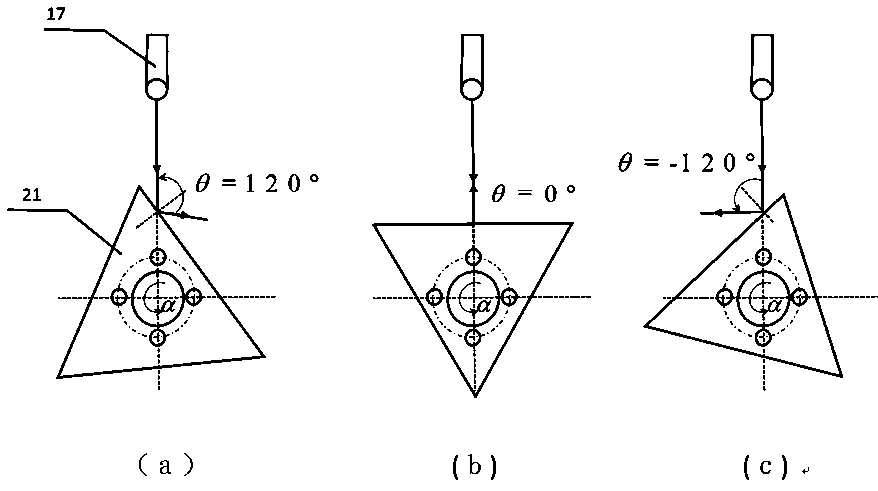

[0027] figure 1 Shown is a general schematic diagram of a surface measurement device based on laser rotation scanning, including three parts, which are respectively a one-dimensional sliding table system 32 (such as figure 2 shown), binocular vision measurement system 33 (such as Figure 5 shown), laser rotation scanning system 34 (such as image 3 shown) and the measured surface 35.

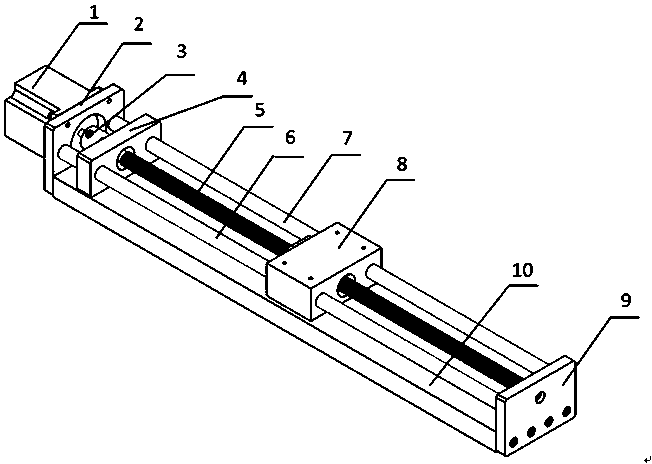

[0028] The one-dimensional slide system (such as figure 2 As shown) consists of the first rotary stepper motor 1, the motor support base 2, the coupling 3, the front support block 4, the ball screw 5, the first optical axis 6, the second optical axis 7, the linear slide table 8, the rear Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com