High-capacity forced-oil circulation air cooler

A technology of strong oil circulation and air cooler, which is applied in the direction of transformer/inductor cooling, transformer/inductor parts, electrical components, etc., which can solve the problem of large number of finned tubes with large wind resistance and increase the loss of cooler auxiliary equipment , The long size of the cooler body and other issues, to achieve the effect of increasing the heat dissipation coefficient K value, improving efficiency and performance, and reducing wind resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

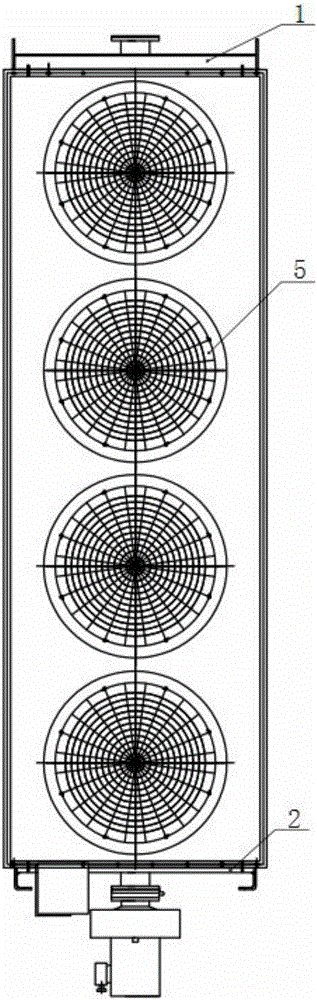

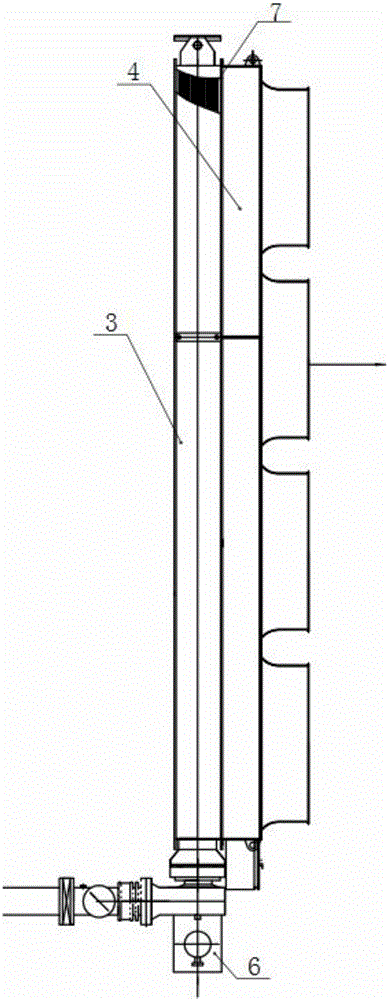

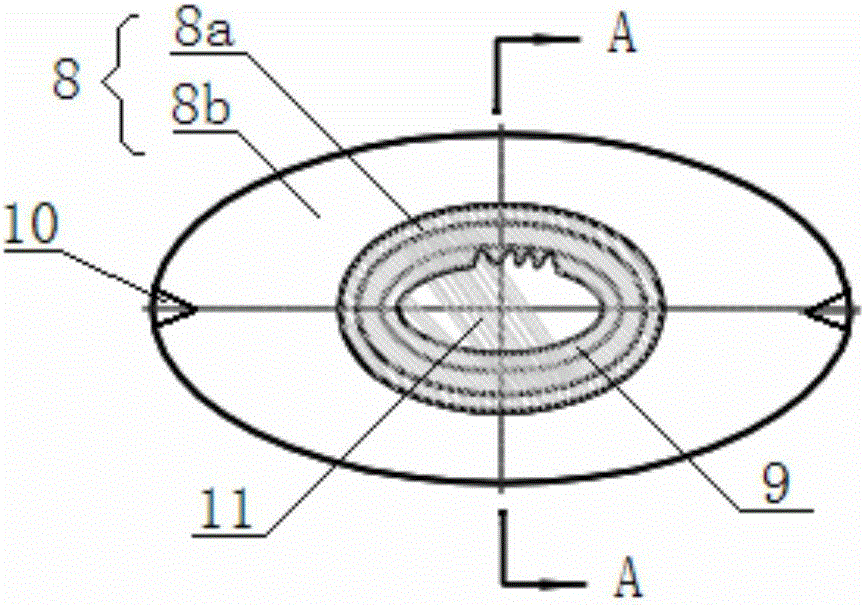

[0028] Such as Figure 1-5 As shown, the large-capacity strong oil circulating air cooler includes: upper oil chamber 1, lower oil chamber 2, cooler body 3, air guide tube 4, cooler fan 5, oil pump 6, tube cluster 7, tube cluster 7 is An elliptical bimetal composite integral rolled finned tube cluster, the cooling tube in the tube cluster 7 is an elliptical bimetallic finned tube, including the flat shape of the integral fin 8b automatically controlled by computer on the outer wall of the elliptical base tube 8a Finned tube 8, an inner ribbed tube 9 with straight ribs on the inner wall of another metal provided on the inner wall of the oval base tube 8a, and corrugated cutouts 10 on the outer edge of the fin 8b, the oval bimetallic finned tube The built-in vortex generator 11 can further improve the heat transfer efficiency on the air side of the abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com