Prefabricated high-voltage all-insulation tubular busbar intermediate joint conductive shielding tube device

A technology for tubular busbars and intermediate joints, which is applied in fully enclosed busbar installations, busbar installations, and cable installations. It can solve the problems of unsatisfactory production, cumbersome production steps, and high production costs, and achieve convenient production and aesthetics. Good, strong protection level effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

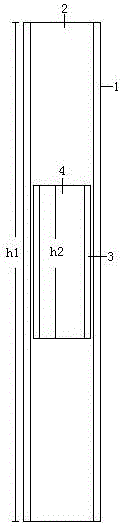

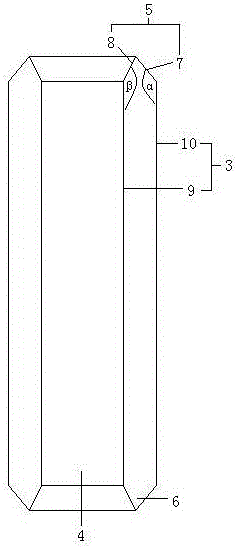

[0017] A prefabricated high-voltage fully insulated tubular bus intermediate joint conductive shielding tube device, the preparation method of which is as follows: ① Mold making: making the shielding tube mold according to the production drawings; ② First cleaning: first installing the shielding tube mold on the flat vulcanization On the machine, wipe the mold of the shielding tube with a release agent; ③ Heating: After wiping, heat the mold of the shielding tube to 50°C for 20 minutes; Wipe the tube mold once; ⑤Injection molding: After wiping, inject liquid conductive adhesive into the shielding tube mold with an injection molding machine until the conductive adhesive overflows from the mold; After completion, turn off the heating system, cool for 30 minutes, and demould to obtain the shielding tube.

Embodiment 2

[0019] A prefabricated high-voltage fully insulated tubular bus intermediate joint conductive shielding tube device, the preparation method of which is as follows: ① Mold making: making the shielding tube mold according to the production drawings; ② First cleaning: first installing the shielding tube mold on the flat vulcanization On the machine, wipe the mold of the shielding tube with a release agent; ③ Heating: After wiping, heat the mold of the shielding tube to 55°C for 25 minutes; Wipe the tube mold once; ⑤Injection molding: After wiping, inject liquid conductive glue into the shielding tube mold with an injection molding machine until the conductive glue overflows from the mold; After the vulcanization is completed, turn off the heating system, cool for 35 minutes, and demould to obtain the shielding tube.

Embodiment 3

[0021] A prefabricated high-voltage fully insulated tubular bus intermediate joint conductive shielding tube device, the preparation method of which is as follows: ① Mold making: making the shielding tube mold according to the production drawings; ② First cleaning: first installing the shielding tube mold on the flat vulcanization On the machine, wipe the mold of the shielding tube with a release agent; ③ Heating: After wiping, heat the mold of the shielding tube to 60°C for 30 minutes; Wipe the mold once; ⑤Injection molding: After wiping, inject liquid conductive adhesive into the shielding tube mold with an injection molding machine until the conductive adhesive overflows from the mold; ⑥Heat up: After injection molding, raise the temperature to 100°C, vulcanize for 2 hours, and vulcanize is completed Finally, turn off the heating system, cool for 40 minutes, and demould to obtain the shielding tube.

[0022] The demoulding machine adopted in the present invention is to prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com