DC/DC converter output control method

A technology of output control and converter, which is applied in the field of DC/DC converter output control, can solve the problems of reduced reliability, small voltage adjustment rate, low efficiency, etc., and achieve the effect of ensuring reliability and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

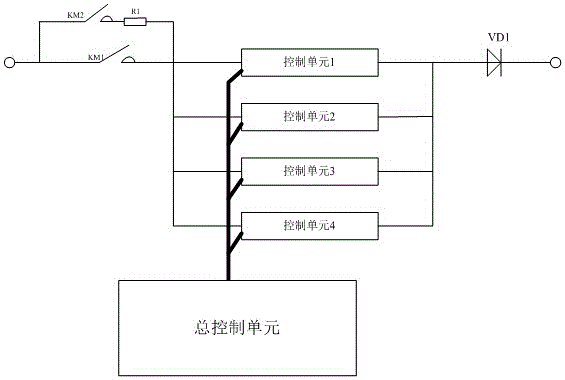

[0019] If the hydrogen fuel cells are internally connected in parallel, because the output voltages of the two hydrogen fuel cells cannot be guaranteed to be consistent, the output current of the two hydrogen fuel cells will be unbalanced, which may cause an overcurrent of one module. The service life of the hydrogen fuel cell is seriously affected by overcurrent. According to the data provided by hydrogen fuel cell manufacturers, the service life of hydrogen fuel is: 12000hrs, if it is often used with overcurrent, the service life is: 2000hrs.

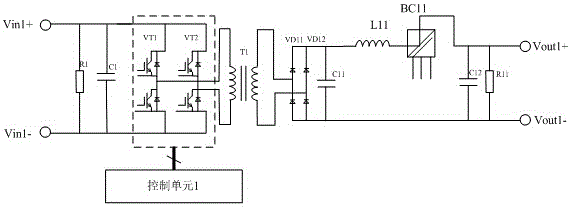

[0020] The total design output power of the hydrogen fuel DC-DC is required to be 200kW, and 4 modules are used in parallel, and the rated power of each module is 50kW. The existing power devices IGBT and rectifier diodes lead to low switching frequency of the module, and the isolation transformer is bulky and heavy. Using multiple modules can increase the switching frequency of the modules and reduce the overall volume and weight. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com