A spliced seedling tray

A plug-and-splicing technology for seedling cultivation, applied in the agricultural field, can solve the problems of low survival rate after planting, easy to disperse pots, and long seedling period, and achieve the effect of improving seedling work efficiency and air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

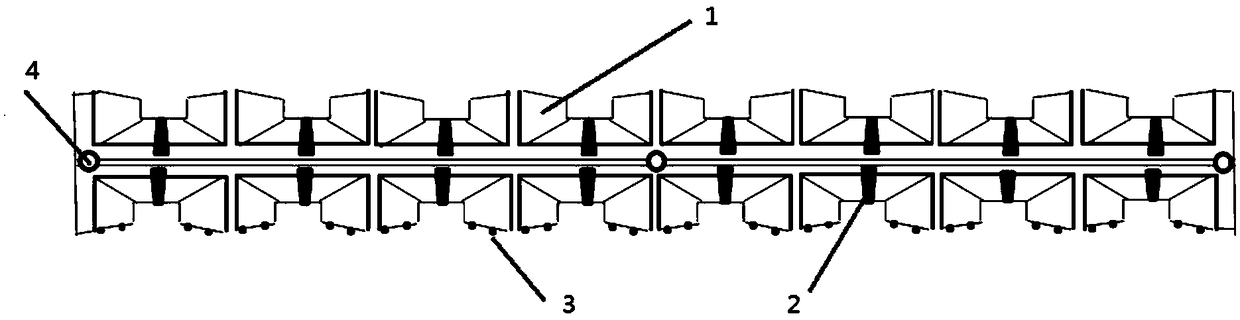

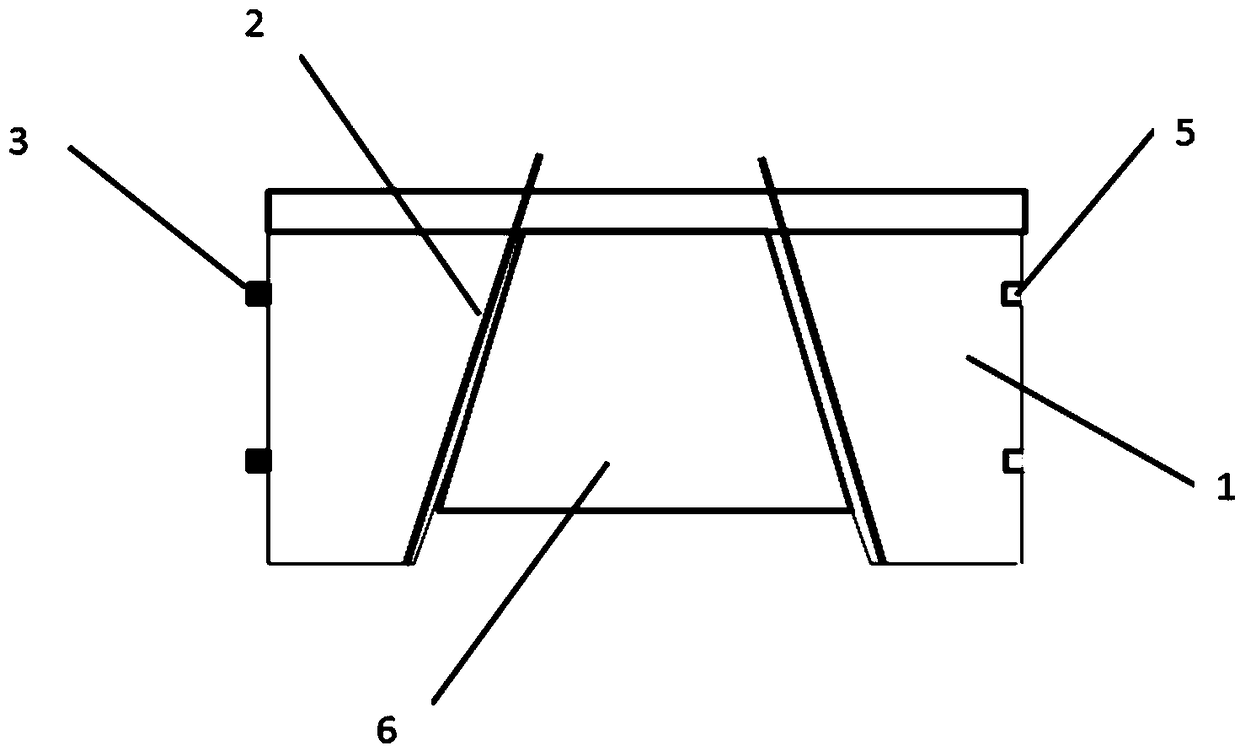

[0023] Such as figure 1 and figure 2 As shown, a spliced seedling tray is spliced by several identical unit members, each unit member is composed of 6-10 groups of tray holes 1, and each group of tray holes 1 has an edge with 4- It consists of 8 tray holes with protrusions 3 and a tray hole with 4-8 grooves 5 on the edge, the two tray holes are connected by reinforcing ribs 6, and each tray hole 1 is attached with a Shrapnel 2, the bottom of the shrapnel 2 is connected to the tray hole 1, the height is higher than the height of the tray hole 1, the shrapnel 2 is 4.5-5.5cm long, 0.5-1cm wide, and the shrapnel 2 is elastic. The height of the shrapnel 2 is 0.5-1 cm higher than that of the tray hole 1 . The tops of the tray holes 1 are connected to form a unit component panel. The tray hole 1 is a square column or cylindrical tray hole with a wide top and a narrow bottom. The height of the tray hole 1 is 4 to 5 cm, the upper opening of the square columnar tray hole is 3 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com