Split type liquid nitrogen tunnel freezer

A split-type, freezer technology, applied in food freezing, meat/fish preservation through freezing/cooling, food science, etc., can solve the trouble of tunnel repair and maintenance, the low utilization rate of liquid nitrogen, and the inconvenient cleaning of liquid nitrogen nozzles and other problems, to achieve the effect of convenient and thorough flushing, easy cleaning and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

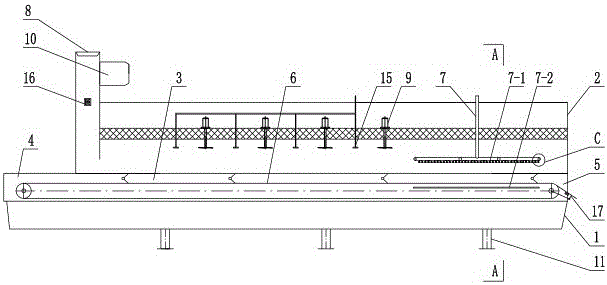

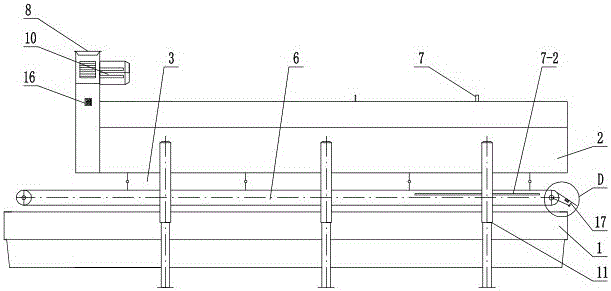

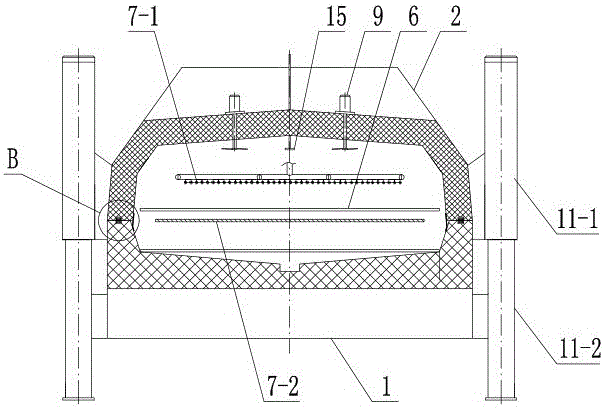

[0030] In the example, such as figure 1 , figure 2 , image 3 As shown, a split-type liquid nitrogen tunnel freezer includes a body and a quick-freezing tunnel 3. One end of the quick-freezing tunnel 3 is provided with a material inlet 4, and the other end is provided with a material outlet 5. Between the material inlet 4 and the material outlet 5 A conveyor belt 6 with adjustable speed is provided, and the body is also equipped with a liquid nitrogen inlet 7, an exhaust gas outlet 8, a uniform temperature fan 9, and an exhaust gas fan 10; the body includes a lower machine base 1 and an upper body 2 with adjustable height , the upper machine body 2 has a first position close to the lower machine base 1 for forming the quick-freezing tunnel 3, and a second position separated from the lower machine base 1 for opening the quick-freezing tunnel 3; The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com