Punching assisting device for fiberglass pipe

A glass fiber tube and auxiliary device technology, applied in metal processing and other directions, can solve the problems of low construction efficiency and large loss of production shutdown.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

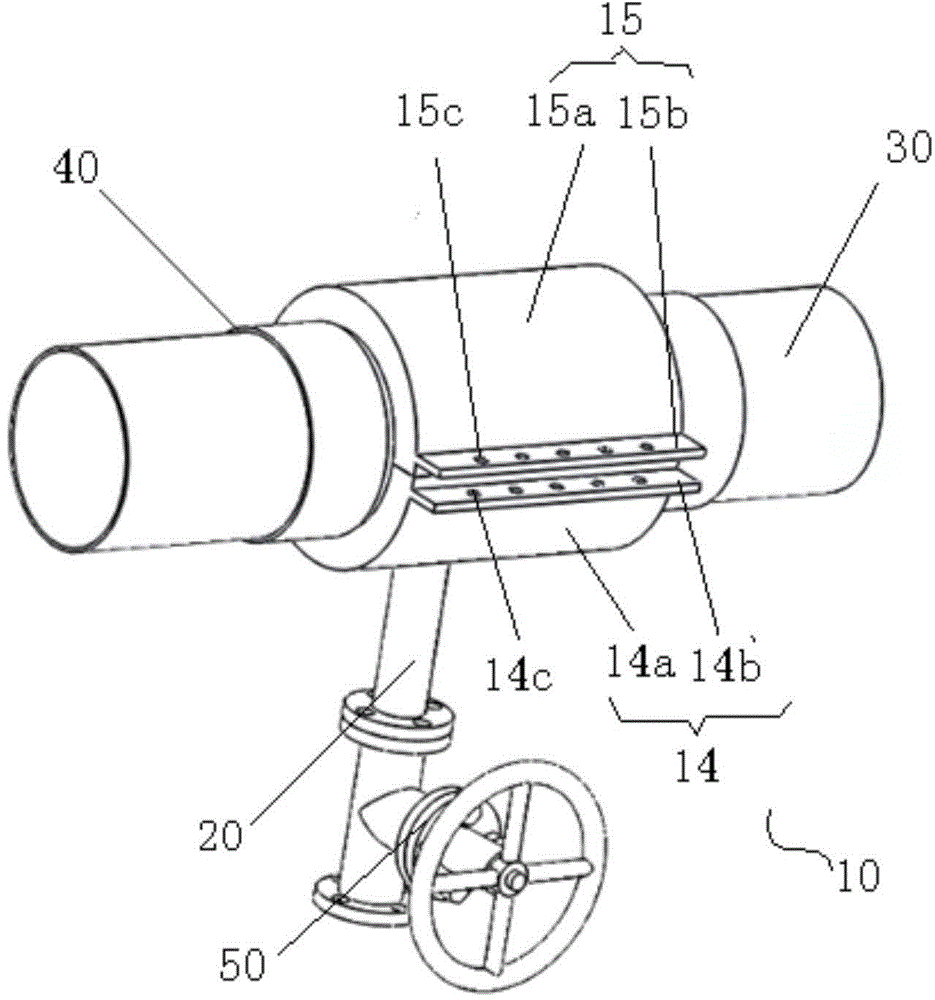

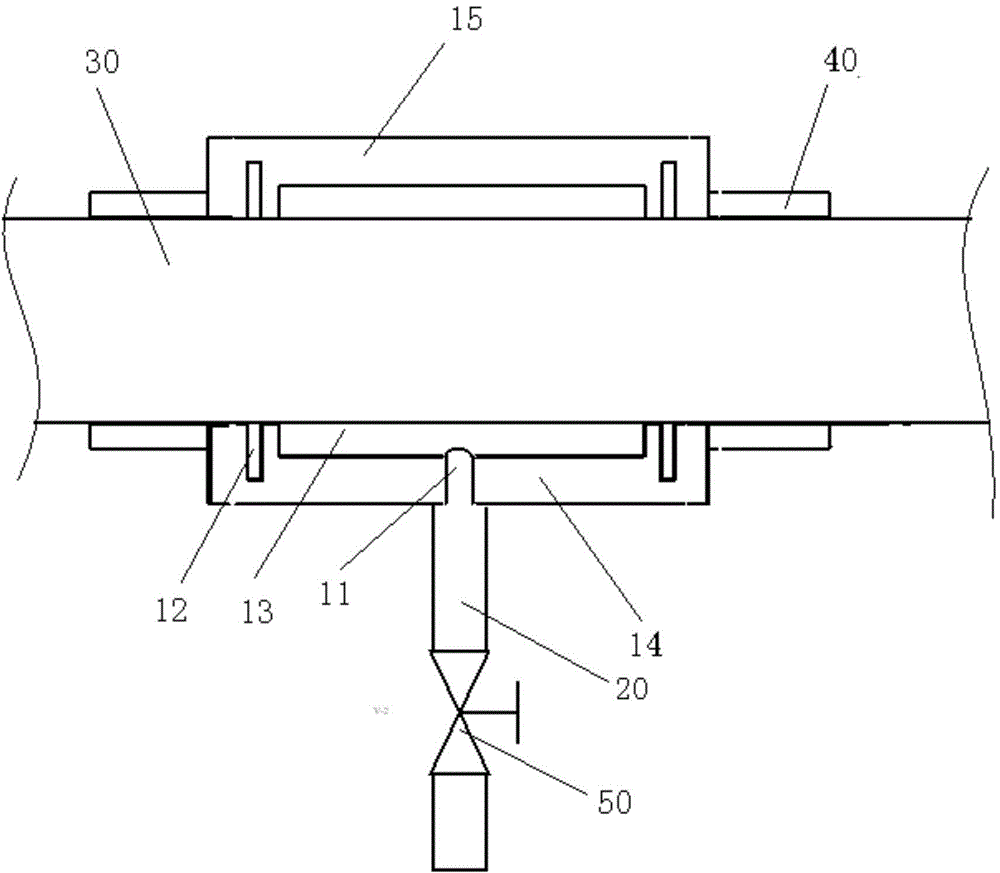

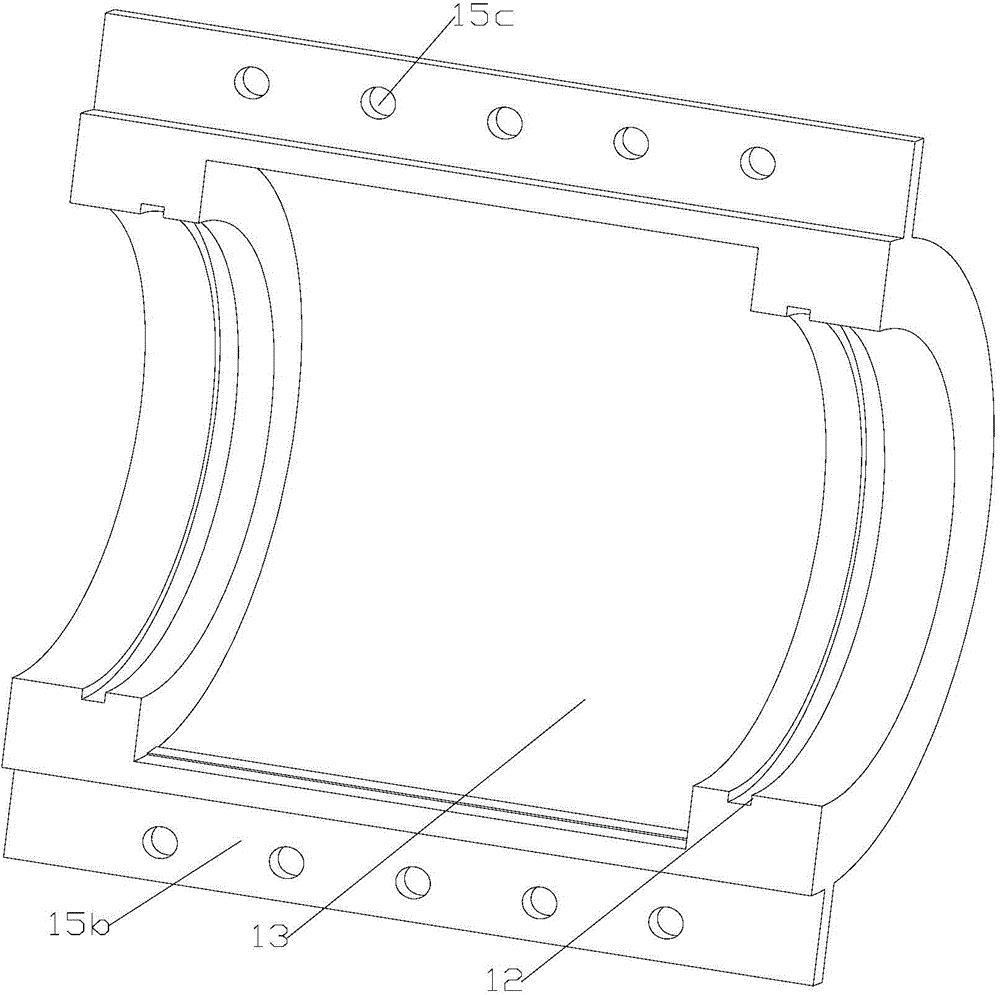

[0080] Take 5.5MPa, 190.5mm inner diameter, and 205mm outer diameter glass fiber pipe 30 with pressurized opening as an example, and the opening diameter is 150mm.

[0081] 1. The fiberglass pipe 30 is reinforced with pressure-opened pipe sections. Determine the 300 mm of the reinforced pipe section with pressure drilling, and grind the surface of the glass fiber pipe 30 to make the surface of the glass fiber pipe 30 rough, and the thickness of the grinding is not more than 0.2 mm. The connecting pipe section 20 with an inner diameter of 155mm is buckled at the pre-opening position of the glass fiber pipe 30 in the middle of the pipe section. Adopt the same type of glass fiber cloth (positioning belt) as the glass fiber pipe 30, and evenly smear the mixed solution of the glass fiber pipe 30 in the original production process of liquid epoxy resin and curing agent on the glass fiber cloth, press the glass fiber pipe 30 According to the requirements of the production process, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com