Improved damping type soft steel arm single-point mooring device

A technology of single-point mooring and soft rigid arm, which is applied in transportation and packaging, ship parts, anchoring arrangements, etc., can solve the problems of mooring platform and mooring device damage, large instantaneous mooring force, etc., and achieve the reduction of huge The effect of force, working life extension, and relative speed reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

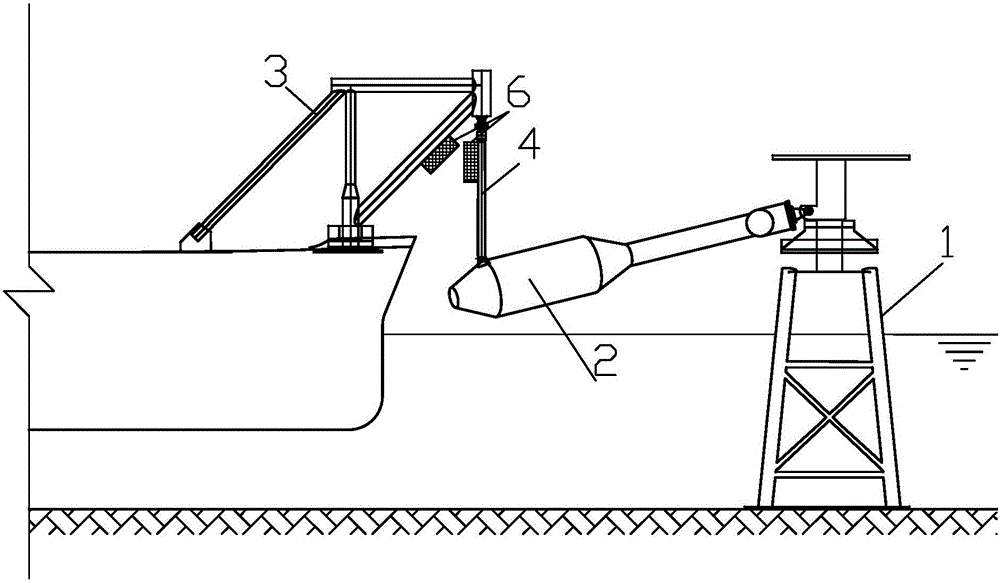

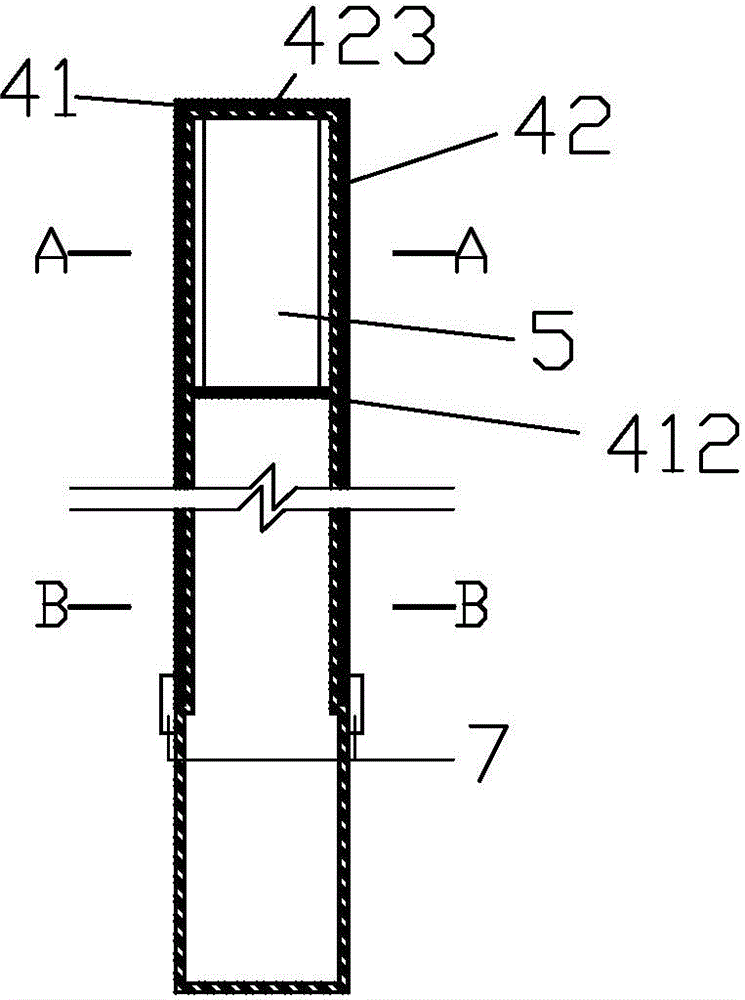

[0052] An improved damping type soft rigid arm single point mooring device, comprising: a mooring tower 1, a mooring arm 2 and a mooring frame, the mooring frame includes a bow bracket 3 and a mooring frame installed on a mooring platform The mooring leg 4, the mooring leg 4 includes an upper casing 41 and a lower casing 42 that can slide relatively, at least one damper 5 is arranged between the upper casing 41 and the lower casing 42, the Both the mooring leg 4 and the bow bracket 3 are provided with a damping box 6, and the two damping boxes 6 are arranged opposite to each other.

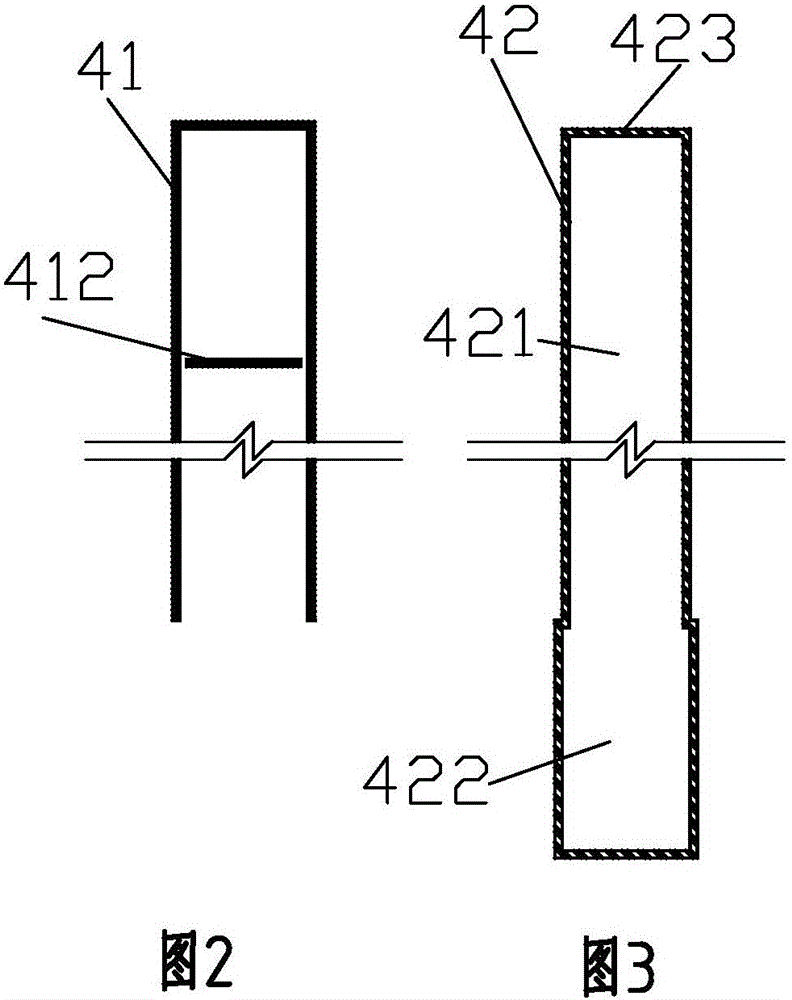

[0053] The upper sleeve 41 is a semi-closed tubular structure with an open end. The inner wall of the upper sleeve 41 is provided with a plurality of pipes extending along the axis of the upper sleeve 41 and evenly distributed with the axis of the upper sleeve 41 as the axis. A slideway 411, the upper casing 41 is provided with a partition 412, and the circumference of the partition 412 is evenly ...

Embodiment 2

[0062] An improved damping type soft rigid arm single point mooring device, comprising: a mooring tower 1, a mooring arm 2 and a mooring frame, the mooring frame includes a bow bracket 3 and a mooring frame installed on a mooring platform The mooring leg 4', the mooring leg 4' includes an upper sleeve 41' and a lower sleeve 42' that can slide relatively, and at least one The damper 5, the mooring leg 4' and the bow bracket 3 are all provided with a damping box 6, and the two damping boxes 6 are arranged oppositely.

[0063] The upper sleeve 41' is a semi-closed tubular structure with one end open, and the inner wall of the upper sleeve 41' is provided with a plurality of bars extending along the axis of the upper sleeve 41' and centered on the axis of the upper sleeve 41'. The shaft is evenly distributed on the slideway 411`, the upper casing 41` is provided with a partition 412`, and the center of the partition 412` is provided with a through hole 413`,

[0064] The lower ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com