Soft rock area surge chamber intersecting tunnel section collapse rapid treatment method

A treatment method and surge chamber technology, applied in water conservancy projects, hydroelectric power stations, infrastructure engineering, etc., can solve the problems of low grouting pressure, low safety risk, and high cost, so as to ensure stability, good effect, and facilitate construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

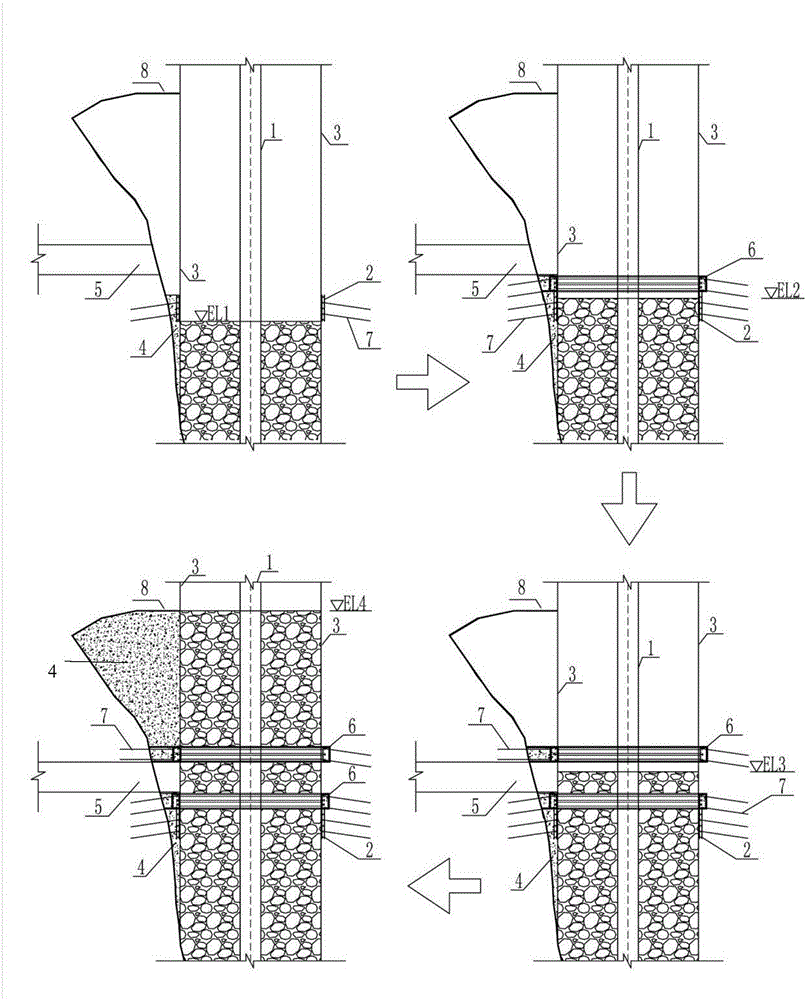

[0027] Such as figure 1 Shown, the soft rock area surge chamber intersecting tunnel section (upper chamber, lower chamber and water diversion tunnel) collapse fast processing method of the present invention, specifically:

[0028] 1) The steel pipe 1 is pre-embedded at the position of the guide shaft in the collapse section, as a slag channel that has penetrated the shaft and the surge chamber;

[0029] 2) Erect the formwork on the design excavation line, reserve grouting pipes on the formwork, use gravel (sand gravel) to backfill on both sides of the formwork to an elevation EL1 ≥ 2.0m from the bottom of the intersecting tunnel section, form a construction platform, and install I-shaped Steel Ring Steel 2. Simultaneously, use the formwork to grout the gravel (sand gravel) in the collapsed area outside the designed excavation line 3 to fo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap