Construction Method of Water Injection Rotary Drilling Bored Pile

A technology of bored piles and construction methods, applied in sheet pile walls, infrastructure engineering, construction and other directions, can solve the problems of excessively thick slag, difficult to guarantee construction quality, and high maintenance costs, and ensure construction quality and hole collapse risk. The effect of reducing and speeding up the progress of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

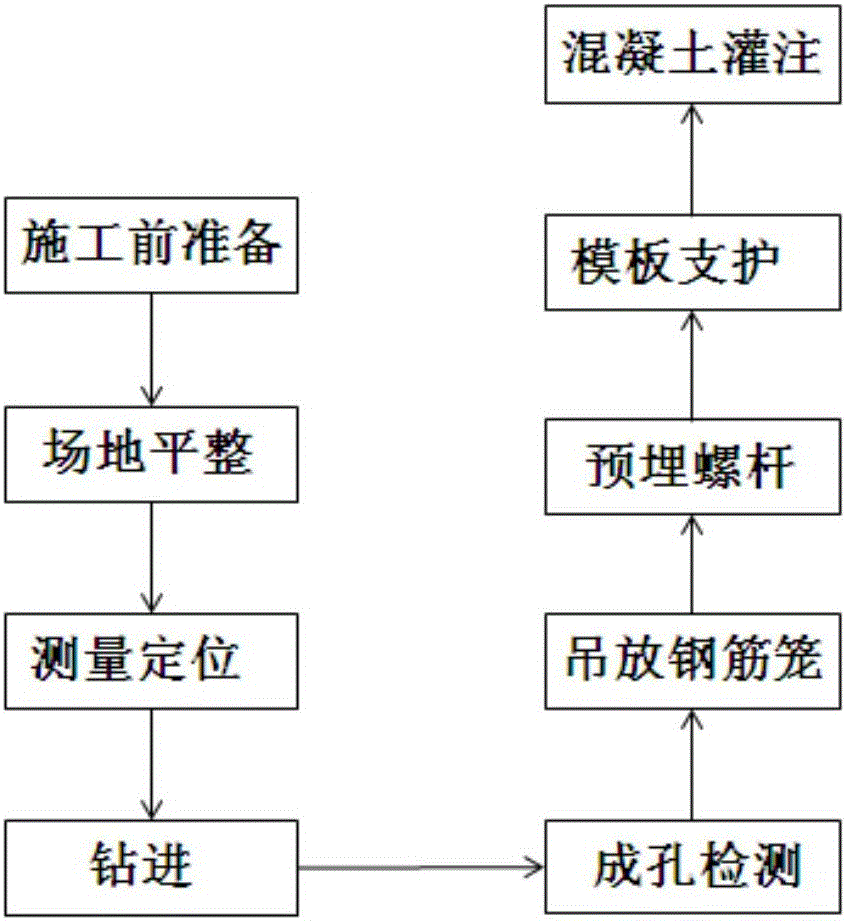

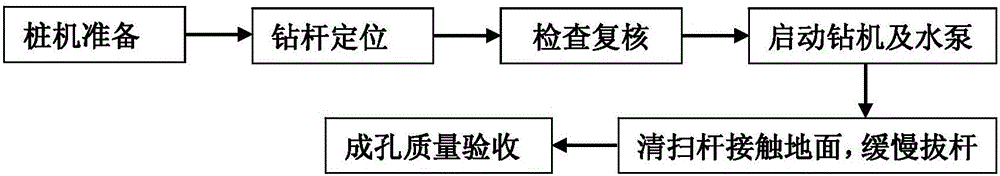

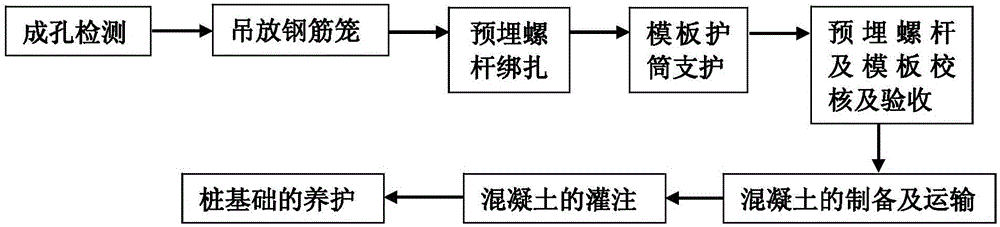

[0032] A kind of construction method of water-injection rotary-drilling bored pile of the present invention, see Figure 1 to Figure 3 , with the following steps:

[0033] (1) First use a total station or theodolite to measure and mark the position of the pile foundation, and the control error should be within the range of 20-25mm;

[0034] (2) After the marking is completed, drive the drilling rig to the designated position, and transform the traditional auger drilling rig. Refer to the figure, and accurately hang and position the drill pipe of the transformed drilling rig to the marked point, and check the water tank and water pump at the same time to ensure the water pressure. In the range of 0.5mpa to 0.8mpa, start the drilling rig and water pump, and control the speed of the rod at a constant speed. In the range of 0.05m / s to 0.1m / s, observe the drilling of the drill pipe and the flow of water from the water tank through the central pipe hole of the drill pipe Inject int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com