Special formula fertilizer for saline-alkali soil and preparation method thereof

A technology for saline-alkali land and fertilizer, which is applied in the field of special formula fertilizer for saline-alkali land and its preparation, can solve the problems of inability to increase crop yield, improve soil, and poor treatment effect, and achieve the effects of good regulation, promotion of crop growth, and good soil physical and chemical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

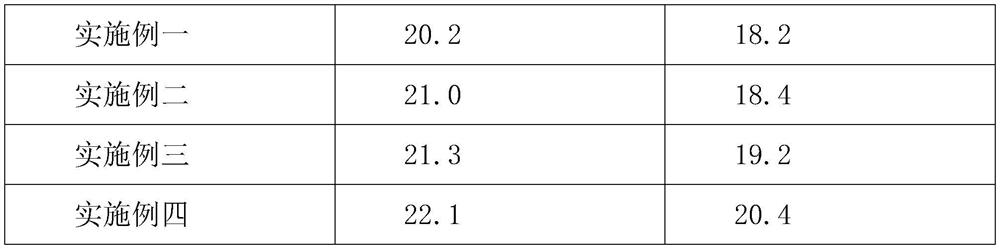

Embodiment 1

[0020] The fertilizer components include 30 parts by weight of urea, 50 parts of biomass straw, 10 parts of ammonium phosphate, 10 parts of furfural slag, 2 parts of Bacillus subtilis, 3 parts of silicate bacteria, 2 parts of salt-tolerant Azospirillum brasiliensis, 4 parts of biochemical fulvic acid, 10 parts of vermicompost, 15 parts of desulfurized gypsum, and 8 parts of soil conditioner.

[0021] In this embodiment, the soil conditioner is a mixture of phosphate rock powder and calcium magnesium phosphate fertilizer.

[0022] The preparation method of the present embodiment comprises the following steps:

[0023] A. After mixing biomass straw, furfural slag, Bacillus subtilis, silicate bacteria, halotolerant Azospirillum brasiliensis, biochemical fulvic acid, and vermicompost, they were added to a fermenter for fermentation to obtain mixture A;

[0024] B. Fully mix the mixture A with urea, ammonium phosphate, desulfurized gypsum, and soil conditioner, then add it to the ...

Embodiment 2

[0031] The fertilizer components include 40 parts by weight of urea, 80 parts of biomass straw, 20 parts of ammonium phosphate, 20 parts of furfural slag, 4 parts of Bacillus subtilis, 6 parts of silicate bacteria, 6 parts of salt-tolerant Azospirillum brasiliensis, 10 parts of biochemical fulvic acid, 20 parts of vermicompost, 25 parts of desulfurized gypsum, and 12 parts of soil conditioner.

[0032] In this embodiment, the soil conditioner is a mixture of phosphate rock powder, calcium magnesium phosphate fertilizer, and phosphogypsum.

[0033] The preparation method of the present embodiment comprises the following steps:

[0034] A. After mixing biomass straw, furfural slag, Bacillus subtilis, silicate bacteria, halotolerant Azospirillum brasiliensis, biochemical fulvic acid, and vermicompost, they were added to a fermenter for fermentation to obtain mixture A;

[0035] B. Fully mix the mixture A with urea, ammonium phosphate, desulfurized gypsum, and soil conditioner, t...

Embodiment 3

[0042] The fertilizer components include 32 parts by weight of urea, 55 parts of biomass straw, 12 parts of ammonium phosphate, 12 parts of furfural slag, 3 parts of Bacillus subtilis, 4 parts of silicate bacteria, 3 parts of salt-tolerant Azospirillum brasiliensis, 5 parts of biochemical fulvic acid, 12 parts of vermicompost, 16 parts of desulfurized gypsum, and 9 parts of soil conditioner.

[0043] In this embodiment, the soil conditioner is a mixture of phosphogypsum and zinc mineral powder.

[0044] The preparation method of the present embodiment comprises the following steps:

[0045] A. After mixing biomass straw, furfural slag, Bacillus subtilis, silicate bacteria, halotolerant Azospirillum brasiliensis, biochemical fulvic acid, and vermicompost, they were added to a fermenter for fermentation to obtain mixture A;

[0046] B. Fully mix the mixture A with urea, ammonium phosphate, desulfurized gypsum, and soil conditioner, then add it to the mixing tank and stir to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com