Construction method for special-shape eave of concrete building

A technology for concrete construction and construction methods, which is applied in construction, building structure, and on-site preparation of building components, etc., can solve the difficulty of formwork support and fixation in grooves, the unsuitable combination of concrete stubble parts, and the inability to ensure the overall quality of concrete, etc. problems, to achieve good economic benefits, save manpower and material resources, reduce the effect of installation workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

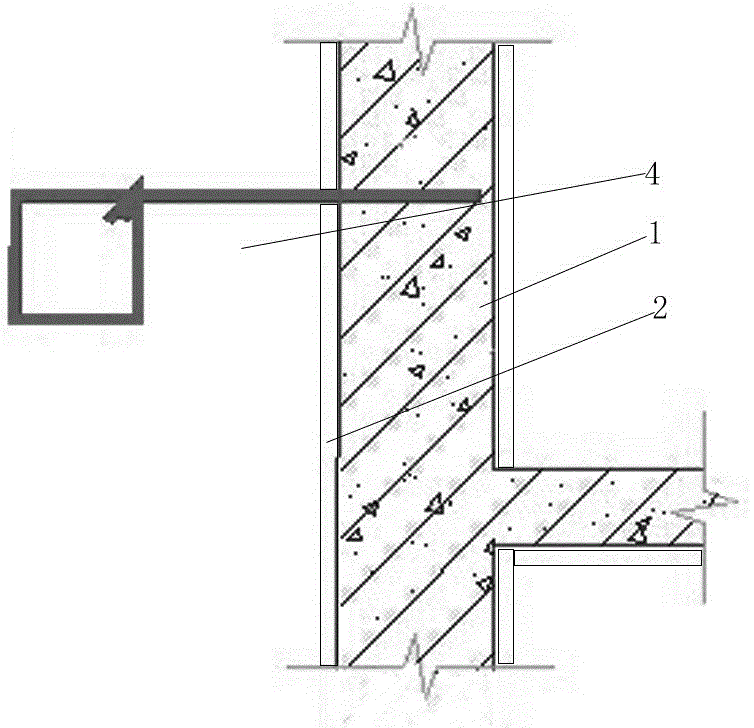

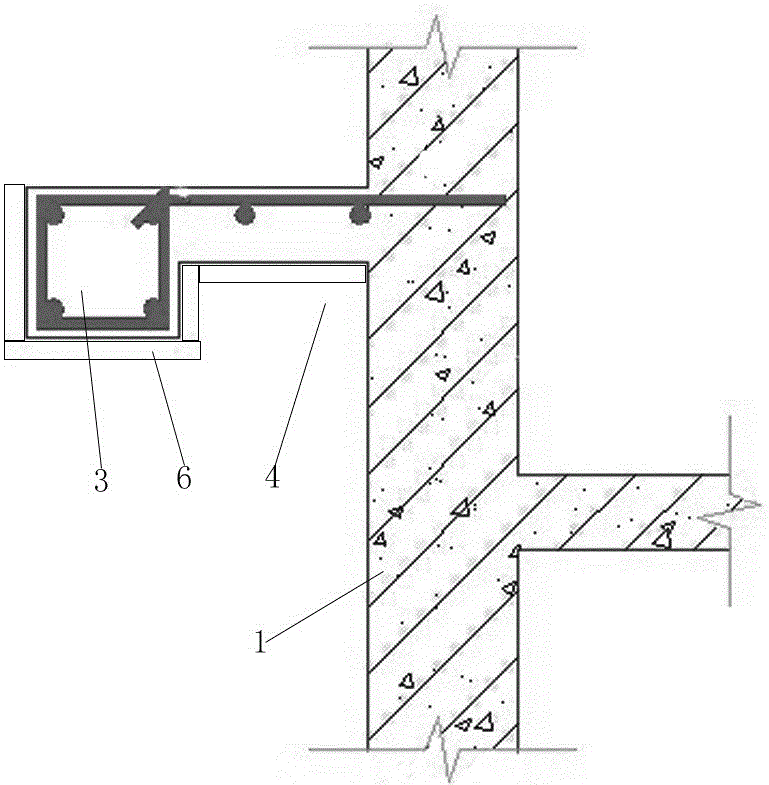

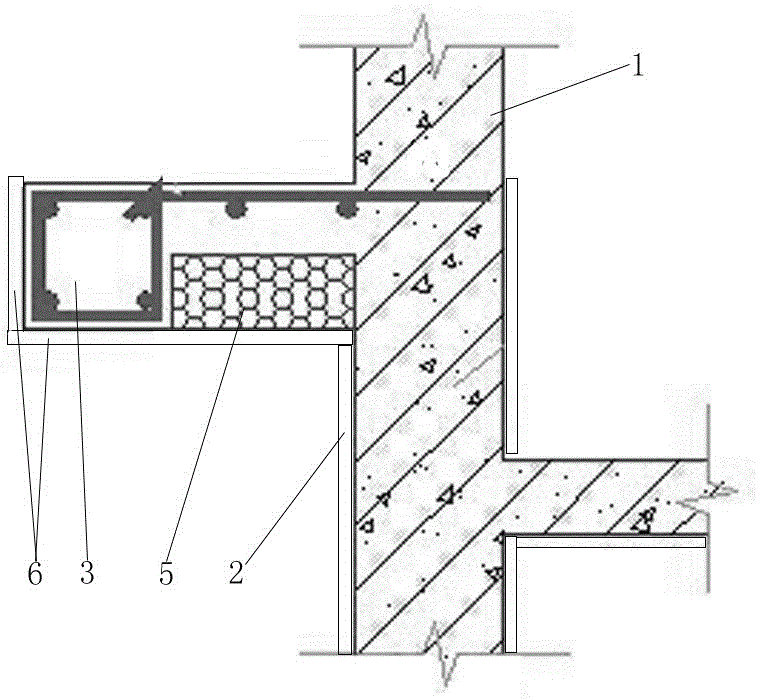

[0017] like image 3 Shown, a kind of construction method of special-shaped eaves of concrete building, comprises the following steps:

[0018] a. Support shear wall formwork 2;

[0019] b. Bind the special-shaped eaves reinforcement at the special-shaped eaves 3 outside the shear wall 1, and fill the groove 4 between the special-shaped eaves reinforcement and the shear wall with a lightweight board 5;

[0020] c. Set the special-shaped eave formwork 6 outside the special-shaped eaves reinforcement;

[0021] d. Pour concrete into the special-shaped eaves formwork warehouse;

[0022] e. After the initial setting of the concrete, remove the formwork and lightweight board 5.

[0023] The lightweight board is a foam board, a gypsum board or a fiber cement sandwich composite board, and it can also be replaced by other lightweight building boards, which can also achieve the purpose.

[0024] The groove space between the special-shaped eaves reinforcement and the shear wall is na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com