Multi-cavity concrete filled steel tube combination column supporting frame system installed in supported and inserted mode

A technology of concrete filled steel tube and supporting frame, which is applied in the direction of construction and building structure, can solve the problems of poor quality of welding seam, shorten the service life of frame, large welding residual stress, etc., so as to improve the service life, ensure the quality of welding seam, The effect of strong carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described in further detail below in conjunction with accompanying drawing:

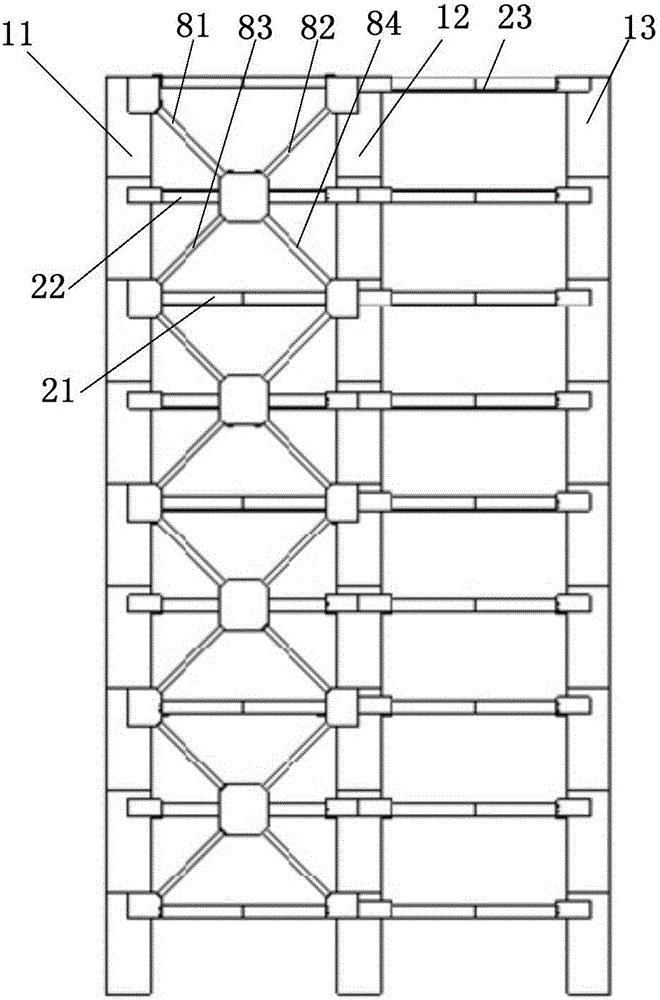

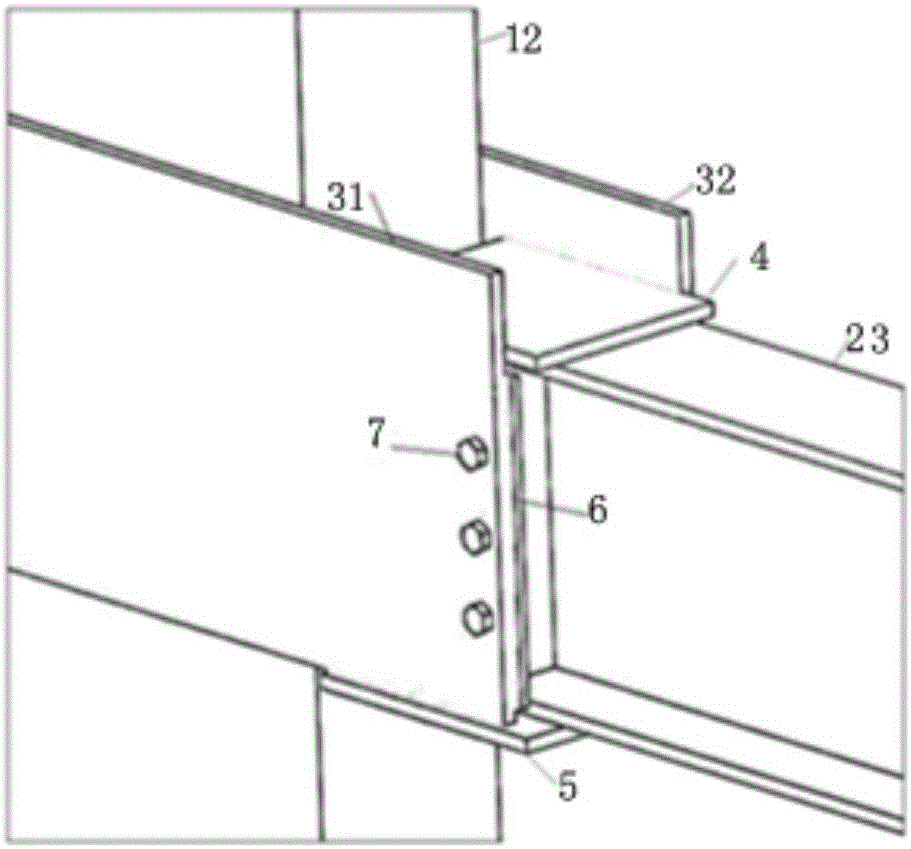

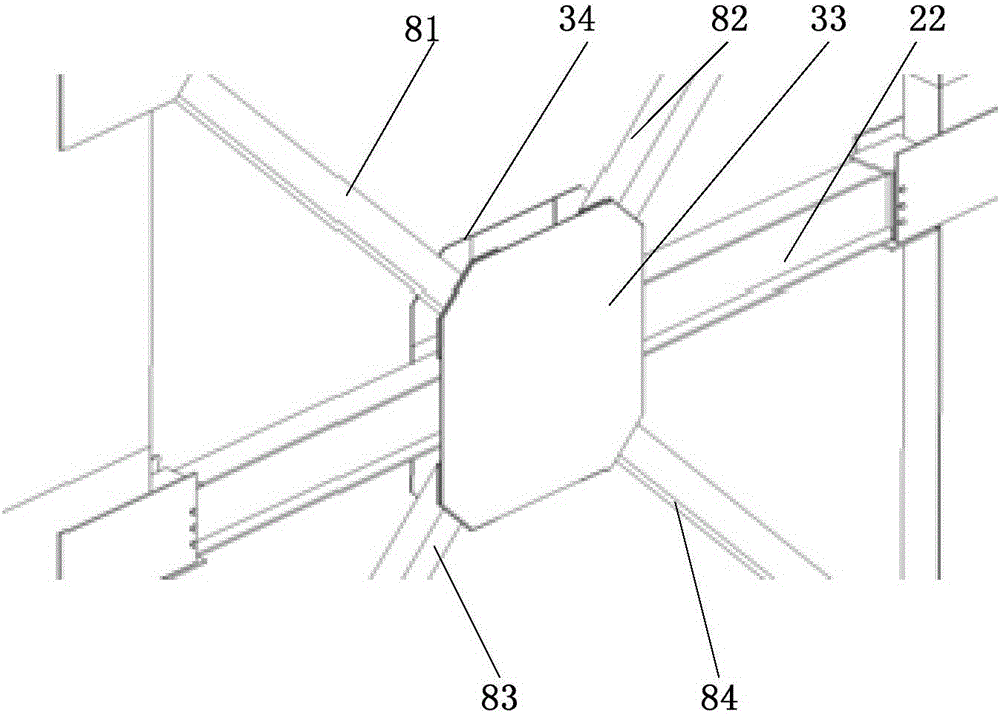

[0030] refer to figure 1 , figure 2 , image 3 and Figure 4 , the multi-cavity concrete-filled steel pipe composite column support frame system for support insertion installation according to the present invention includes a first multi-cavity steel pipe concrete composite column 11, a second multi-cavity steel pipe concrete composite column 12 and a third multi-cavity steel pipe concrete composite column distributed in sequence from left to right. Cavity concrete-filled steel pipe composite column 13; several first H-shaped steel beams 21 are arranged between the first multi-cavity steel-filled concrete composite column 11 and the second multi-cavity steel-filled concrete composite column 12, and each first H-shaped steel beam 21 runs from top to bottom The bottom is distributed in sequence, and a support system is provided between the two first H-shaped steel be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com