Ceramic tile leveling adjustment block and ceramic tile pavement system and method employing same

An adjustment block and leveling technology, applied in the direction of building, building structure, etc., can solve the problems of gaps that cannot meet expansion, low work efficiency, and high labor costs, achieve high efficiency, avoid too wide and too narrow, and reduce fine-tuning time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

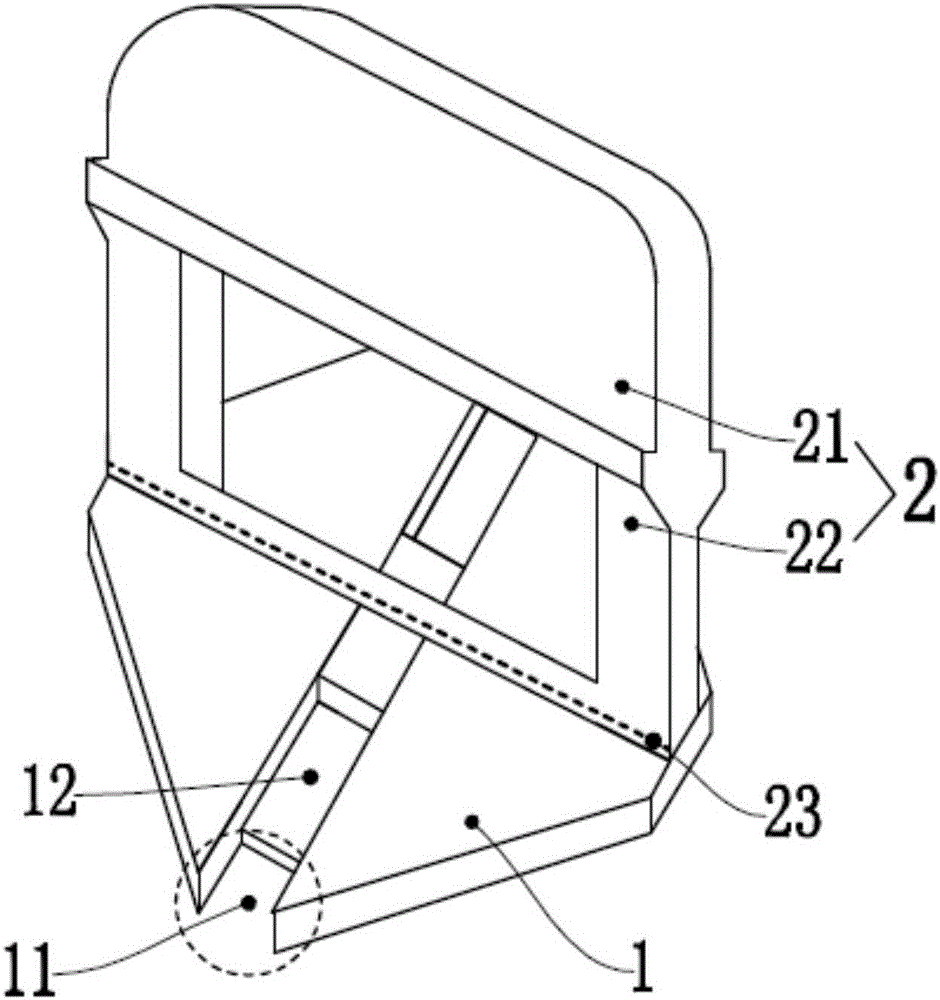

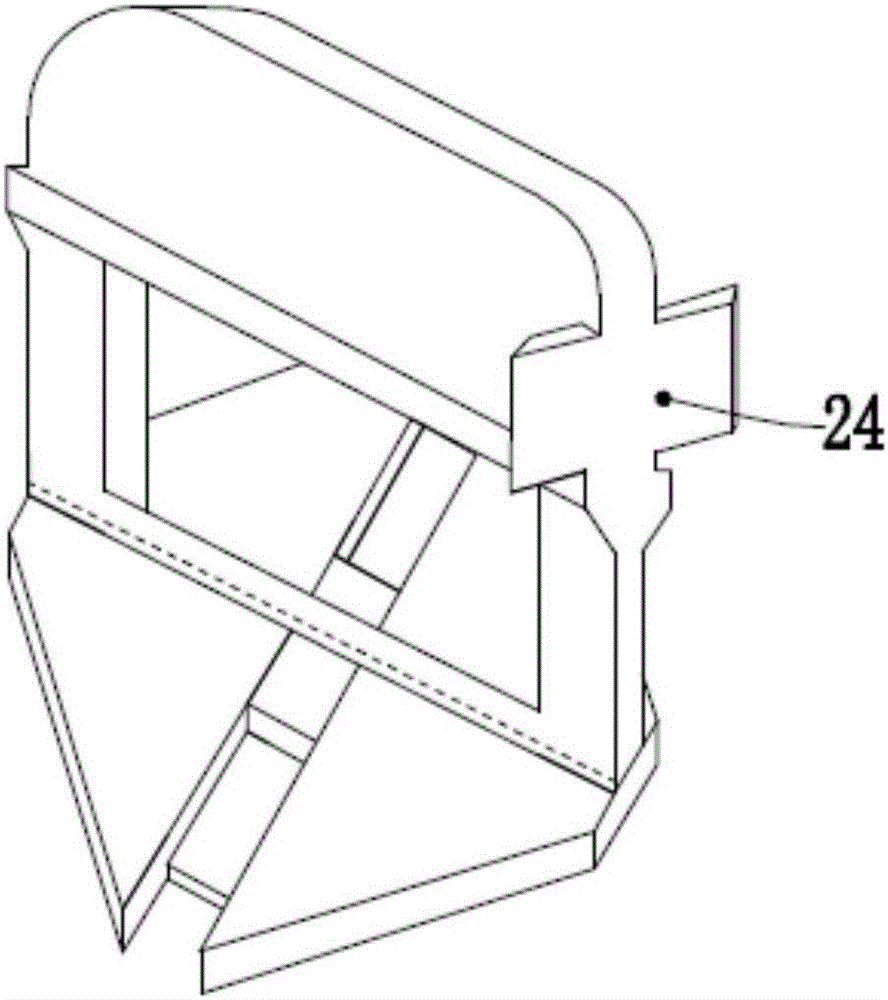

[0034] The leveling adjustment block of the ceramic tile of the present embodiment (as figure 1 shown), including a flat base 1 and a door-type pulling member 2, the door-type pulling member 2 is provided with a crossbeam 21 and a fixing part 22, and one end of the two fixing parts 22 is respectively fixed to the ends of the crossbeam 21 The other end of the fixing part 22 is connected to the flat base 1 .

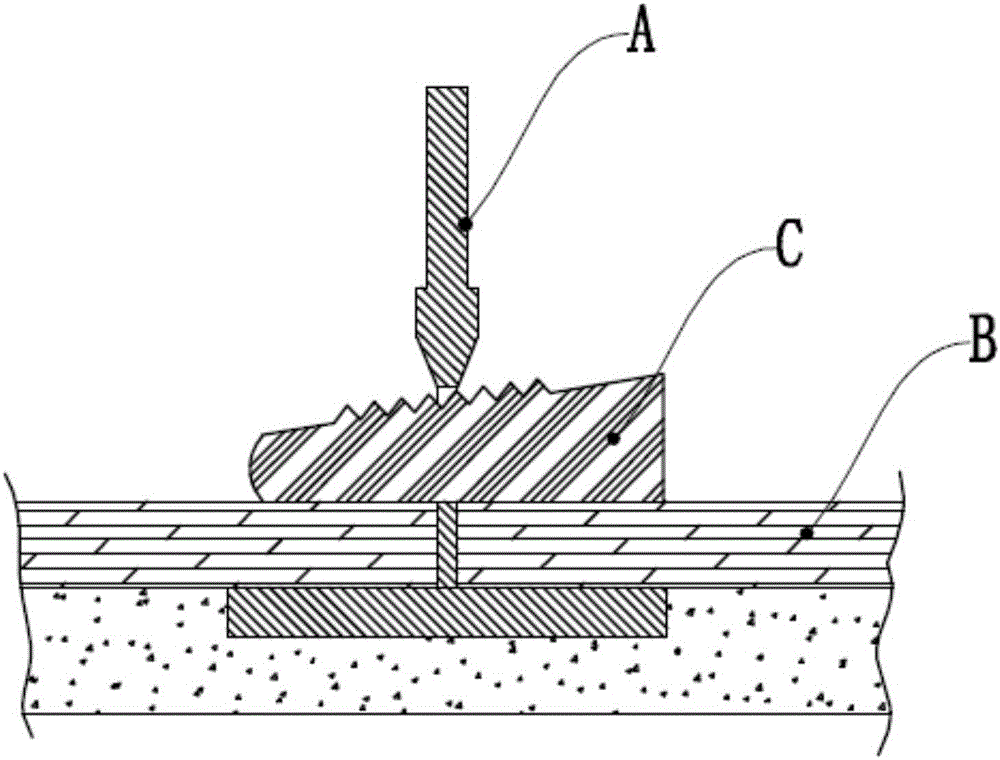

[0035] The tile laying system (such as Figure 3-5 shown), including the tile leveling adjustment block A, tile B and locking bead C; the locking bead C includes a locking surface C1 and a locking plane C2, and the locking surface C1 is inclined to the locking pressure Plane C2, the surface of the locking surface C1 is provided with locking sawtooth C11; the leveling adjustment block A is arra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com