Method of laser welding metal plate

A laser welding and sheet metal technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of waste of raw materials, high cost, complicated process, etc., achieve good welding quality, improve success rate, width and melting deep fit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

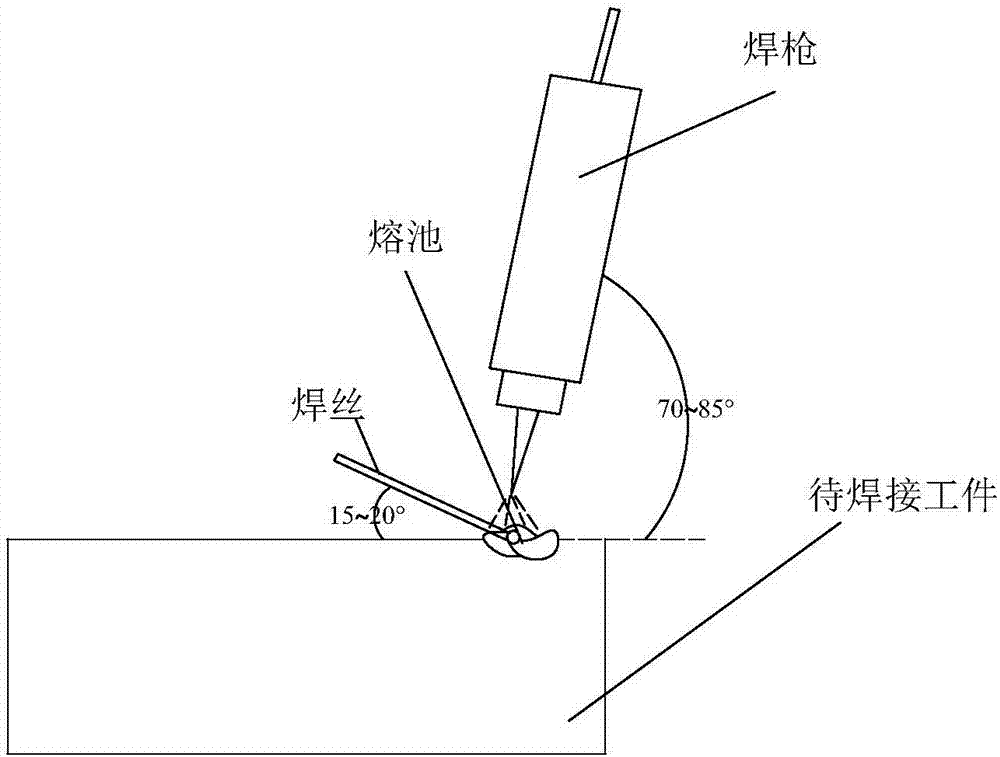

[0030] see figure 1 As shown, the embodiment of the present invention provides a method for laser welding sheet metal, the welding torch used is semiconductor laser and CO 2 Laser compound welding torch, wherein, CO 2 The laser spot is located within the semiconductor laser spot, and the semiconductor laser and CO 2 The direction of the slow axis of the laser is consistent, when welding, CO 2 The laser is located in the normal welding position, the semiconductor laser is located on one side of the weld, and the semiconductor laser is focused on the sheet metal by CO 2 on the molten pool produced by the laser.

[0031] The method includes the following steps:

[0032] S1. Clean the surface of the workpiece to be welded, remove oil, rust and other attachments, and prevent attachments from entering the welding area during the welding process...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com