Aluminum alloy honeycomb core flame arrester

An aluminum alloy and flame arrester technology, which is applied in the direction of machines/engines, noise reduction devices, engine components, etc., can solve the problems of reduced power and economy of explosion-proof diesel engines, small air flow area, and heavy weight of flame arresting cores. Lightweight, easy to maintain, and good fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, the present invention will be further described

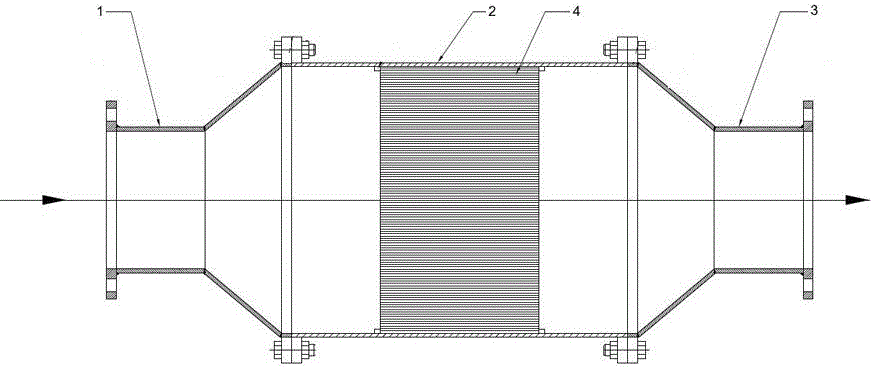

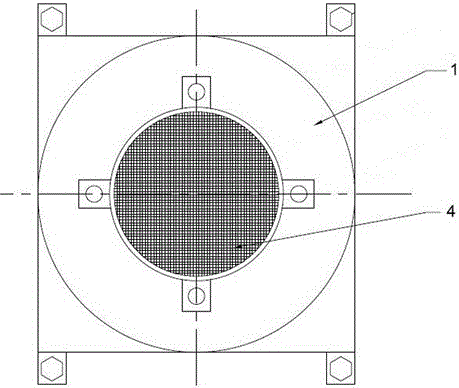

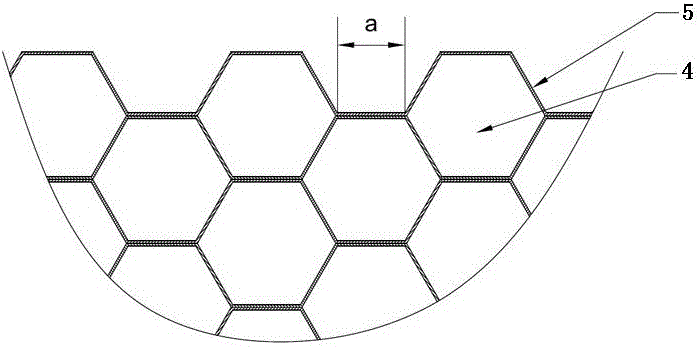

[0016] An aluminum alloy honeycomb core flame arrester, as shown in the figure, includes an exhaust gas inlet section 1, a fire arresting section 2, and an outlet section 3, and a fire arresting core 4 is arranged inside the fire arresting section 2, and the fire arresting core 4 is located in the middle of the fire arresting section 2 , keep a distance of 30mm-50mm from the entrance section and the exit section, and the flame retardant core 4 is made of aluminum alloy corrugated plates 5 overlapped and bonded to form a rectangular fire retardant core with a honeycomb airflow channel; the filling length of the fire retardant core along the air flow direction 50mm-100mm, the side length of the honeycomb-shaped airflow channel of the fire-resistant core is a=0.5mm-1.5mm, and the thickness of the aluminum alloy corrugated plate 5 is 0.025mm-0.08mm.

[0017] The flame arrester ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com