A car charging socket

A car charging and socket technology, applied in electric vehicle charging technology, charging stations, electric vehicles, etc., can solve the problems of short life, high temperature, large contact resistance, etc., to reduce temperature rise, improve plug life, reduce The effect of small contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical problems solved by the present invention, the technical solutions adopted, and the technical effects obtained easy to understand, the specific implementation manners of the present invention will be further described below in conjunction with the specific drawings.

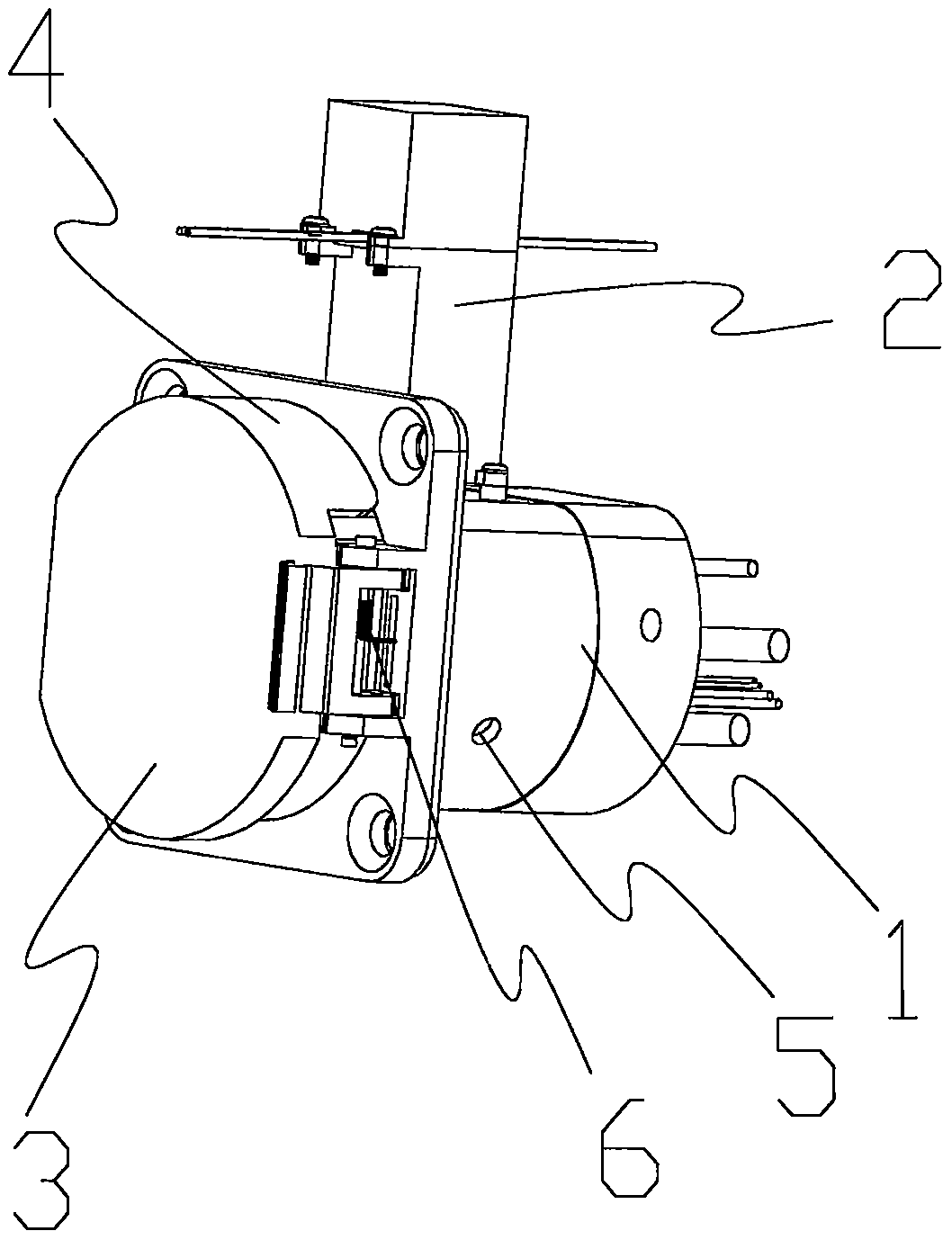

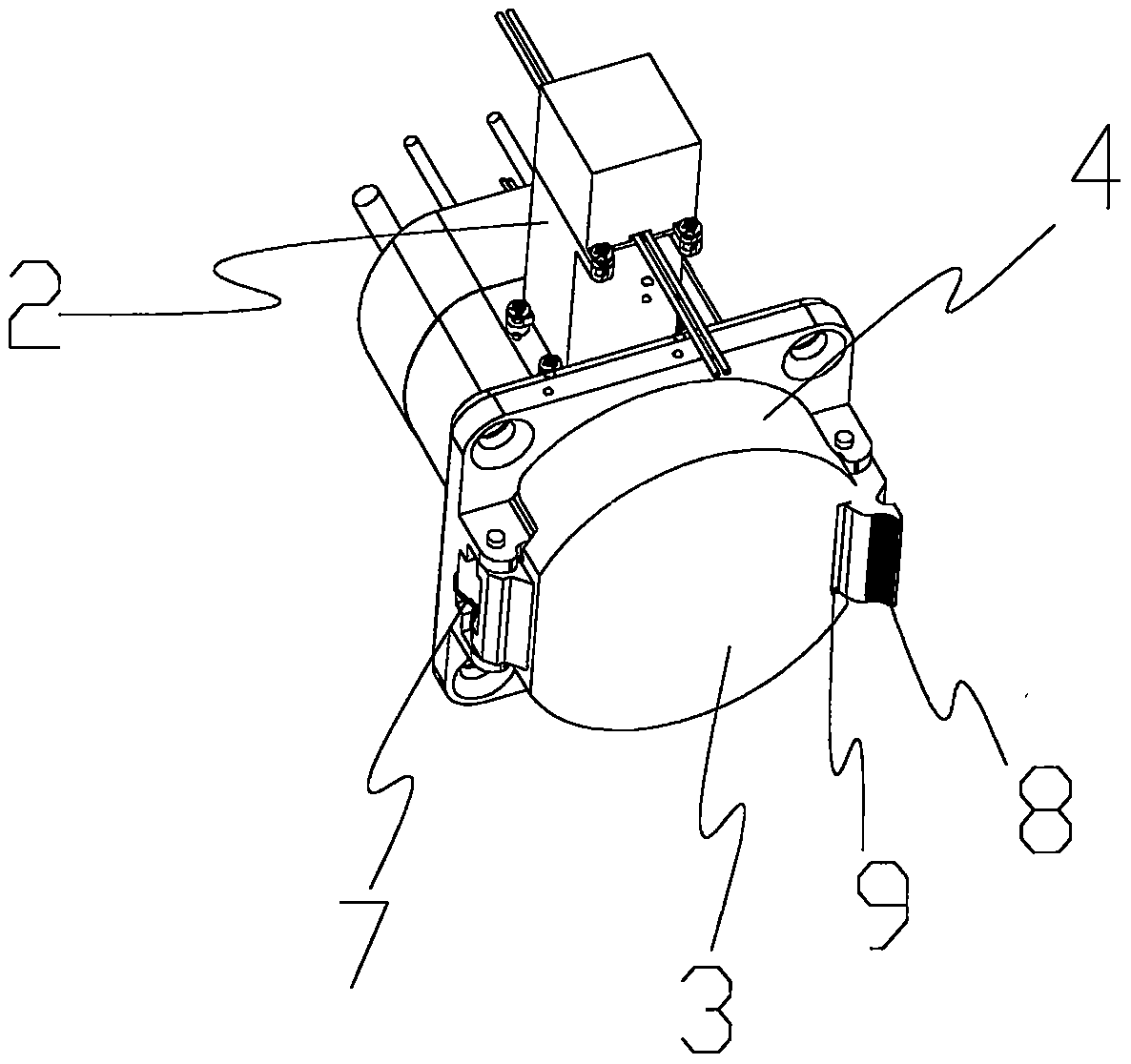

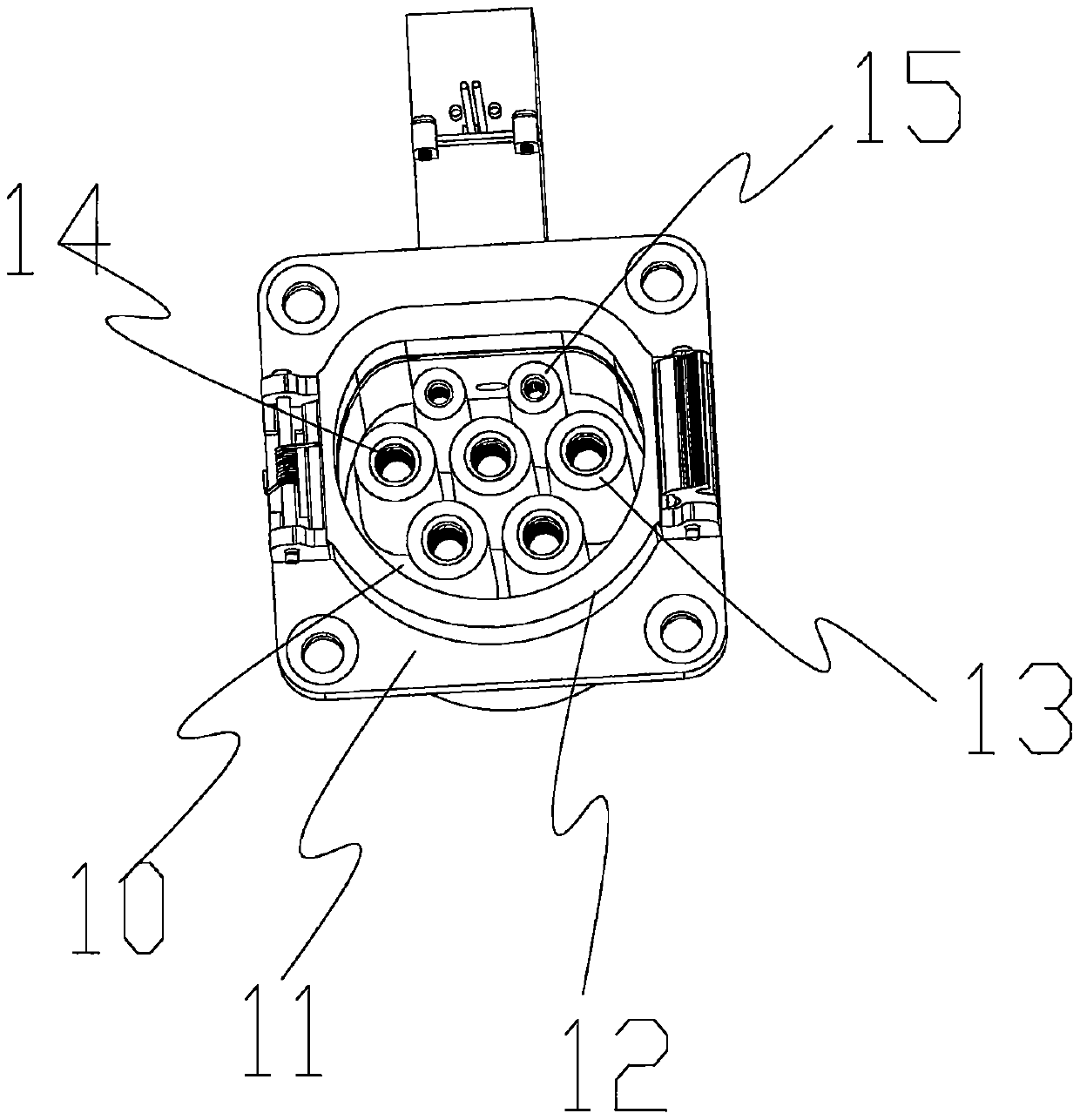

[0015] refer to Figure 1 to Figure 4 , the present invention provides a car charging socket, which includes a base 1 with an inner cavity 10, a plurality of contact terminals are arranged in the inner cavity 10 of the base 1, and the base 1 of the present invention preferably has two ends Through, wherein its open end is used for charging equipment insertion, and its tail can be provided with a tail end cap 23, and the tail end cap 23 is fixed on the tail of the base 1, thereby sealing the opening of its tail. The contact terminals can be directly fixed on the end cover 23 and protrude into the inner cavity 10 of the base 1 .

[0016] A flange 12 surrounding the opening of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com