Position indicating module and stylus pen

A technology of stylus and electrodes, which is applied in the direction of user/computer interaction input/output, instrument, calculation, etc., which can solve the problems such as difficult pen refill replacement and achieve the effect of easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

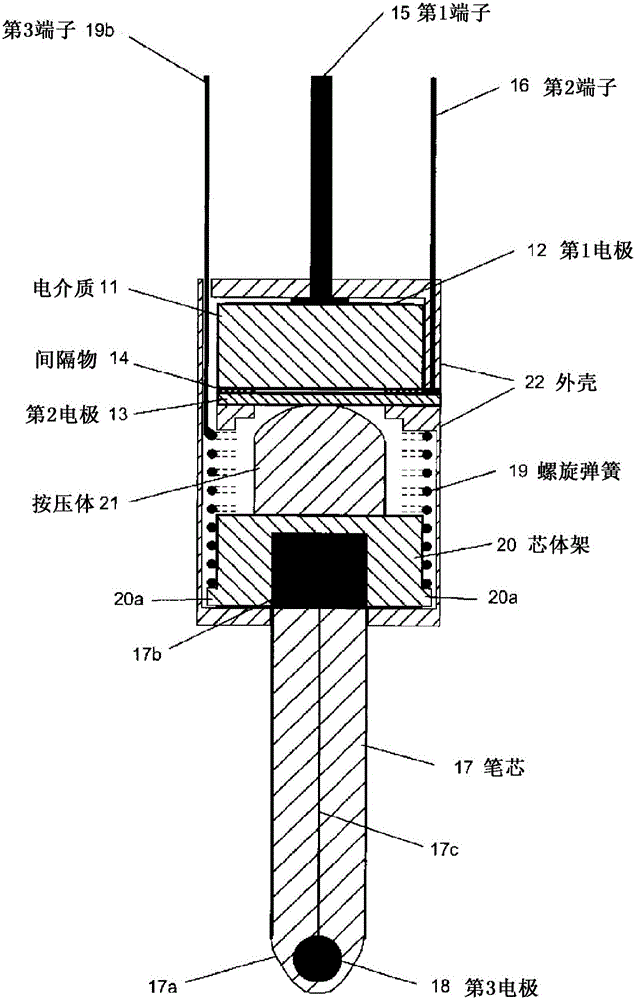

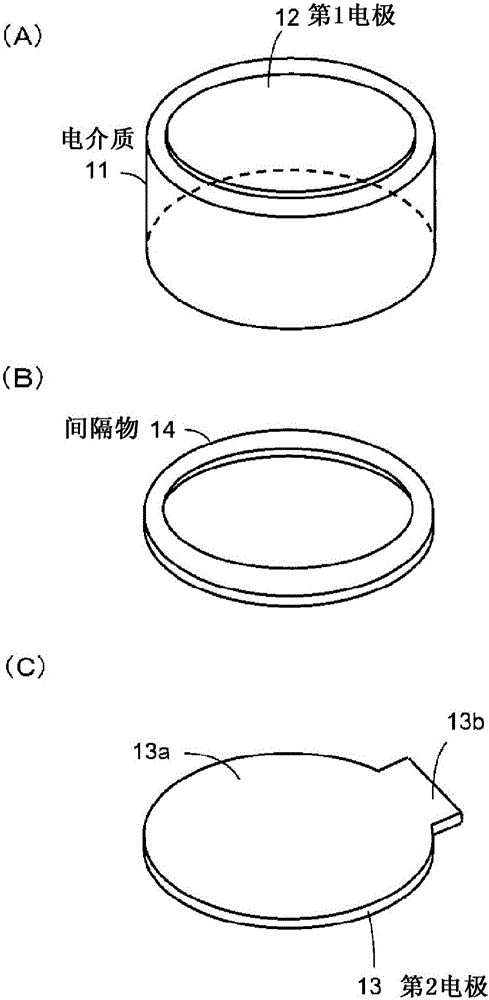

[0055] figure 1 It is a figure which shows the structure diagram (central cross-sectional view) of an example of the position indication module of 1st Embodiment of this invention. exist figure 1 Among them, 11 denotes a substantially disk-shaped dielectric, 12 denotes a first electrode provided on the first surface of the dielectric 11, and 13 denotes a second electrode made of a flexible material. The second electrode 13 is disposed on the second surface side of the dielectric 11 opposite to the first surface with the ring-shaped spacer 14 interposed therebetween. For the second electrode 13 , for example, conductive rubber can be used, or a material obtained by vapor-depositing a conductive substance on one surface of polyimide can be used.

[0056] figure 2 It is a perspective view when the dielectric 11, the spacer 14, and the second electrode 13 are respectively arranged in disassemble. At least the surface 13 a side of the second electrode 13 in contact with the sp...

no. 2 Embodiment approach

[0069] [Second Embodiment (Modification of First Embodiment)]

[0070] Figure 5 It is a figure which shows the structure diagram (central sectional view) of an example of the position indication module of 2nd Embodiment, and figure 1 Parts having the same configuration as the position indicating modules of the first embodiment shown are denoted by the same reference numerals. The second embodiment has a lot in common with the first embodiment, so here only figure 1 The different sections are explained.

[0071] 23 represents a coil spring formed of a conductive material, which is basically the same as that used in the first embodiment Figure 4 The coil spring 19 shown is the same, but does not have a portion corresponding to the straightly extending portion, ie, the terminal 19b. The coil spring 23 is inserted into the core frame 20 similarly to the coil spring 19 of the first embodiment, and is in contact with the protruding portion 20 a to be electrically connected.

...

no. 3 Embodiment approach

[0078] Figure 7 is a diagram showing a structural view (central sectional view) of an example of the position indication module of the third embodiment, and figure 1 Parts having the same configuration as the position indicating modules of the first embodiment shown are denoted by the same reference numerals.

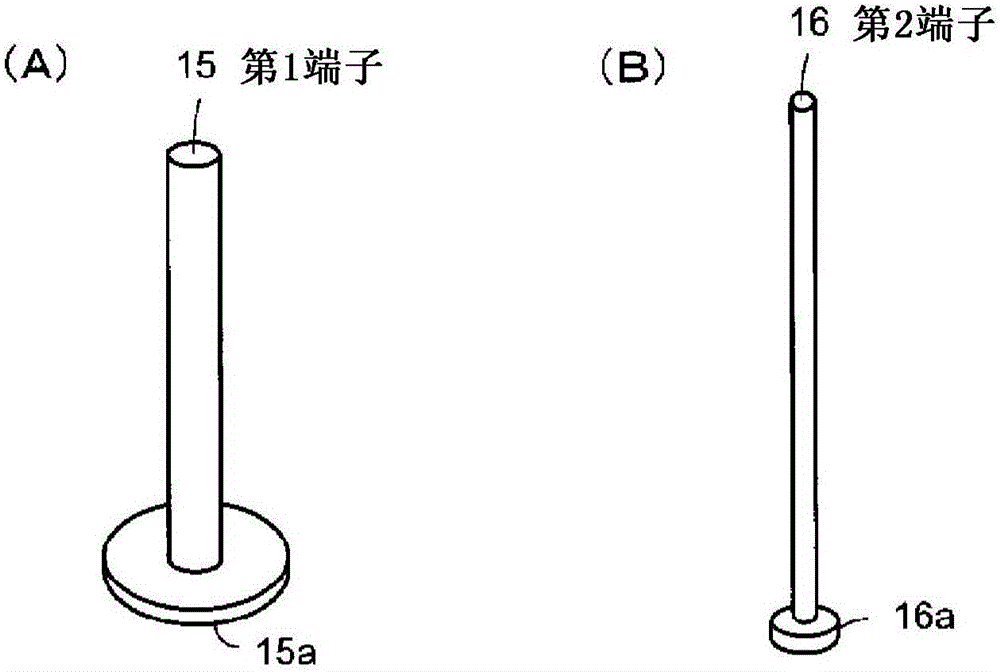

[0079] That is, 11 denotes a substantially disk-shaped dielectric, 12 denotes a first electrode provided on the first surface of the dielectric 11, and 14 denotes a spacer. 15 denotes a first terminal formed of metal, which is electrically connected to the first electrode 12 of the dielectric 11 . 16 denotes a second terminal formed of metal. 17 denotes a substantially rod-shaped refill, and a third electrode 18 is embedded in the front end 17a. A conductive substance is applied to the connection end 17 b of the lead 17 , and the connection end 17 b is electrically connected to the third electrode 18 via a conductor 17 c provided inside the lead 17 . The configurat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com