Electric machine having in each case at least two clamping protrusions for attaching a permanent magnet

A permanent magnet and clamping technology, which is applied in the direction of magnetic circuits, electrical components, electromechanical devices, etc., can solve the problems of difficult installation of permanent magnets, and achieve the effects of small torque fluctuation, small positioning torque, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

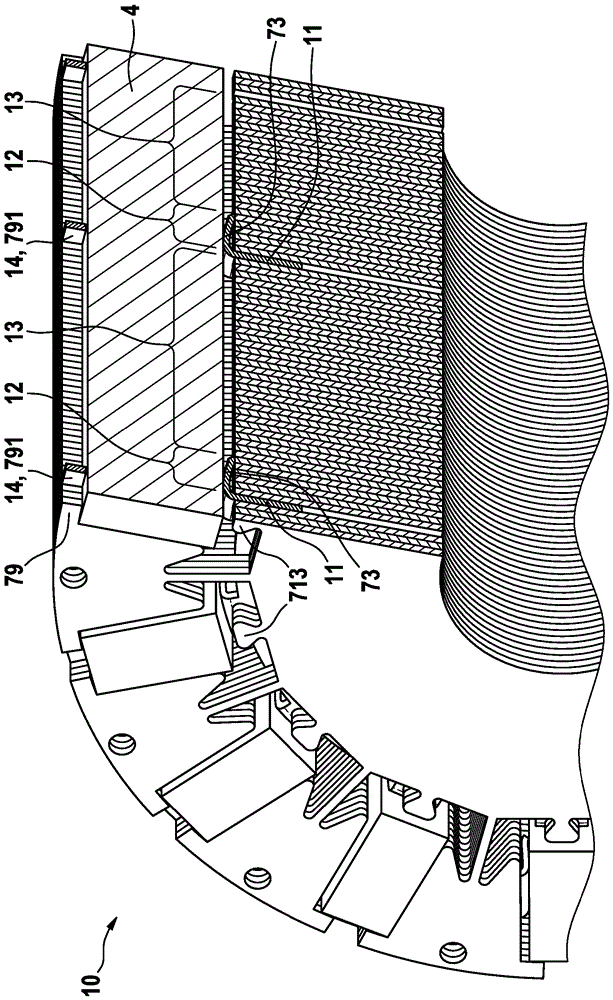

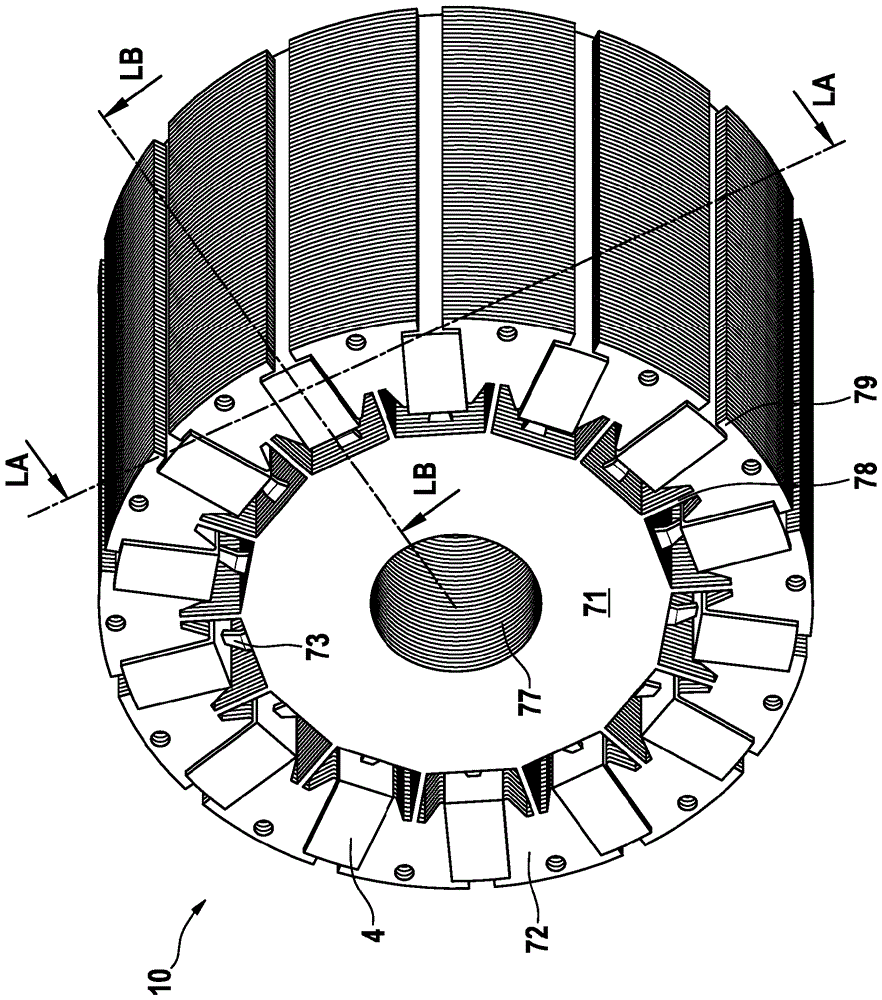

[0053] The spoked rotor 10 has a base body 1 which is produced as a lamellar pack of a plurality of laminae 11 , 12 , 13 . Figure 2(a) shows the clamping foil 11 of the spoked rotor 10, Figure 2(b) shows the balancing foil 12 of the spoked rotor 10, and Figure 2(c) shows the Middle lamination 13 of spoked rotor 10 . The finished substrate 1 is shown in FIG. 2( d ). And Figures 2(e)-(g) respectively show a spoked rotor 10 with permanent magnets 4 arranged in the base body (1).

[0054] The lamellae 11 , 12 , 13 are preferably produced in one piece as punched-out parts from web material. For the clamping laminations 11 , either the steels conventionally used for laminations of such rotors 10 , preferably ferrous, or spring steels can be used. For the remaining sheets 12, 13 conventional steel is used.

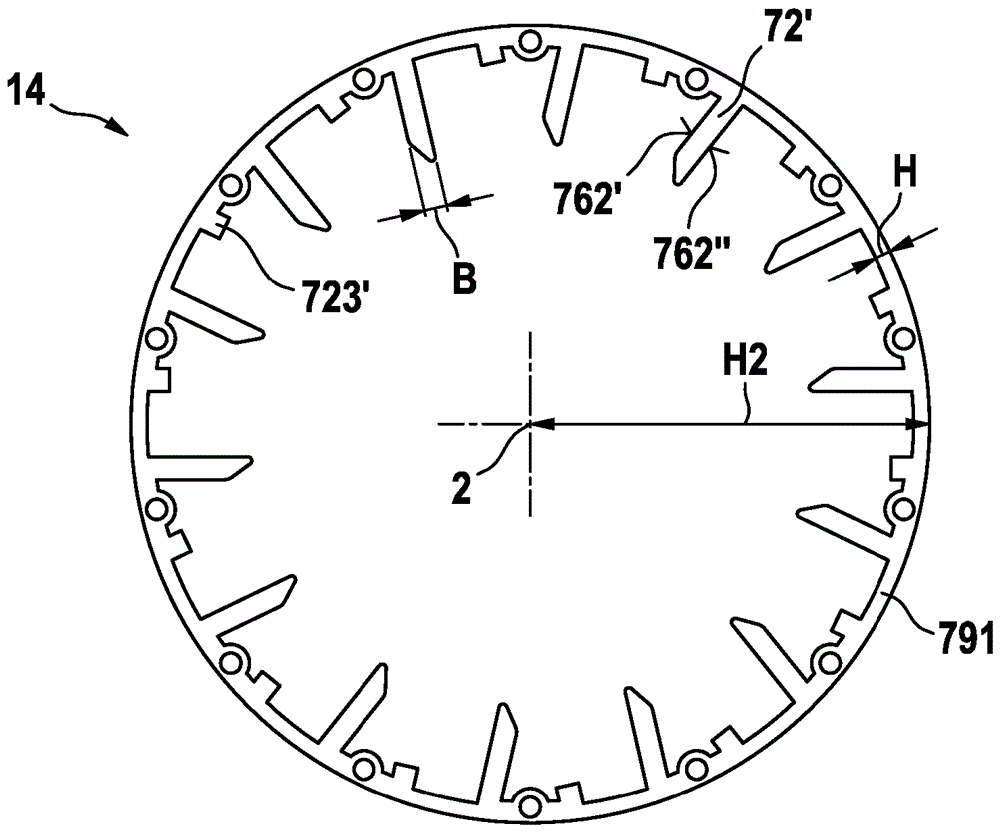

[0055] The clamping lamination 11 has an inner ring 71 which in turn has a pole shoe 72 arranged on the inner ring 71 . The inner ring 71 extends concentrically around the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com