Rice grain conveying mechanism, rice grain conveying method and rice cooker

A technology of conveying mechanism and electric cooker, which is applied to cooking utensils, household appliances, applications, etc., can solve the problems of low degree of automation, complex overall structure, inconvenience in use, installation, and production, etc., and achieves simple structure, strong wind power, and communication channels. short path effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

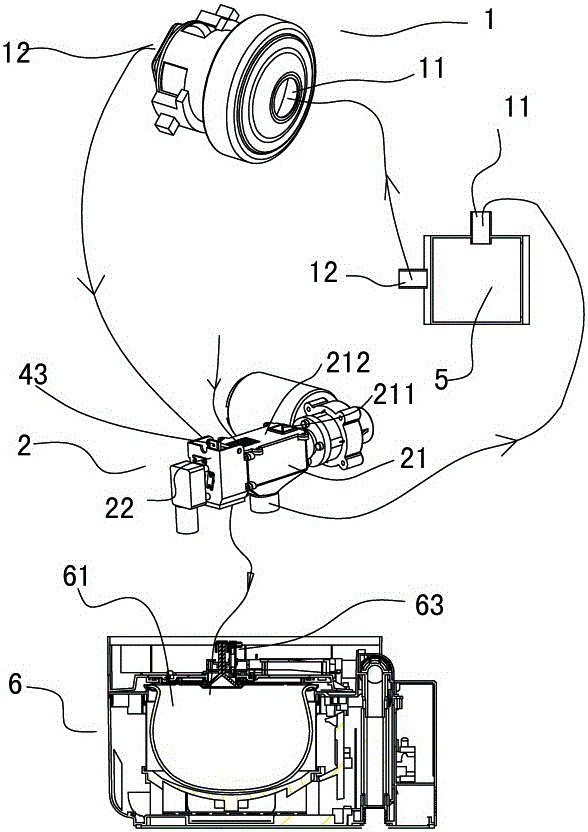

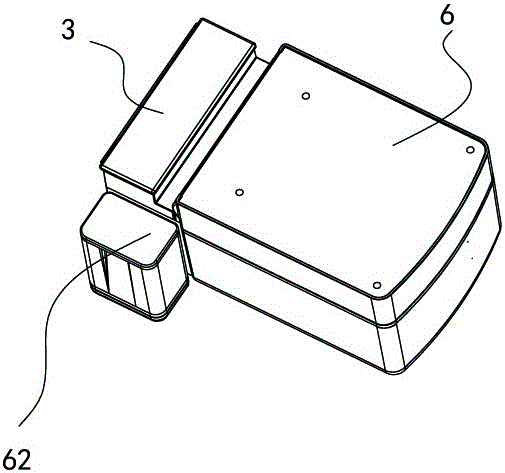

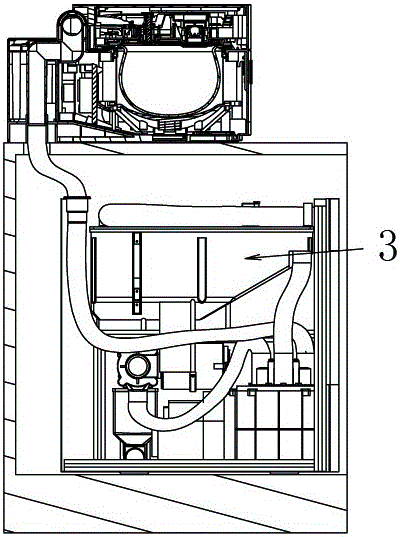

[0022] Please refer to Figure 1 to Figure 4 , the rice conveying mechanism in the figure includes an air pressure generator 1, a dry cleaning assembly 2, and a dustbin 5. The air pressure generator 1 is a fan with suction and blowing function, which has an air outlet 11 and an air inlet 12 . The dry cleaning assembly 2 includes a dry cleaning cavity 21 , a storage cavity 22 , and an extruder 4 ; the dustbin 5 has an air inlet 11 and an air outlet 12 . The dry cleaning cavity 21 is used to accommodate rice grains, which are extruded by the screw 42 and the mesh screen in the extruder 4 when the rice grains are introduced from the rice bin 3 through the material guide port 211 above the screw 42. For this structure, please refer to Chinese patent application number 2015207513145 The disclosed structure. The rubbish that produces in the extruding process is sent in the dustbin 5 under the effect of wind force. Between the above-mentioned dry-cleaning cavity 21 and the materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com