Slag steel dry magnetic separation purifying technology and equipment

A slag steel and magnetic separation technology, which is applied in the field of metallurgy, can solve the problems of magnetic spike phenomenon, magnetic separation efficiency decline, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

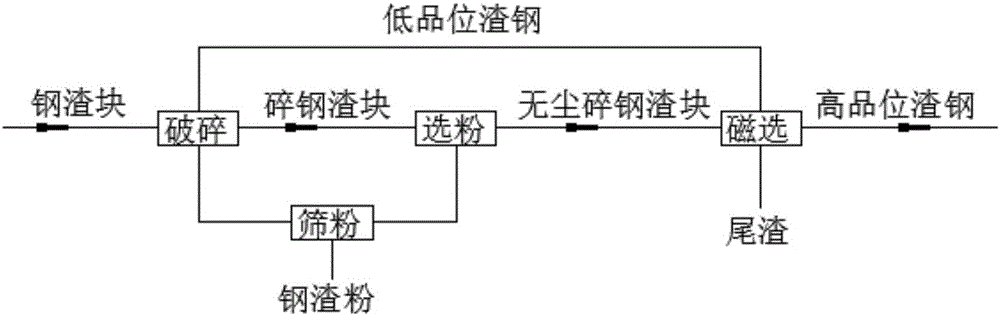

Method used

Image

Examples

Embodiment 1

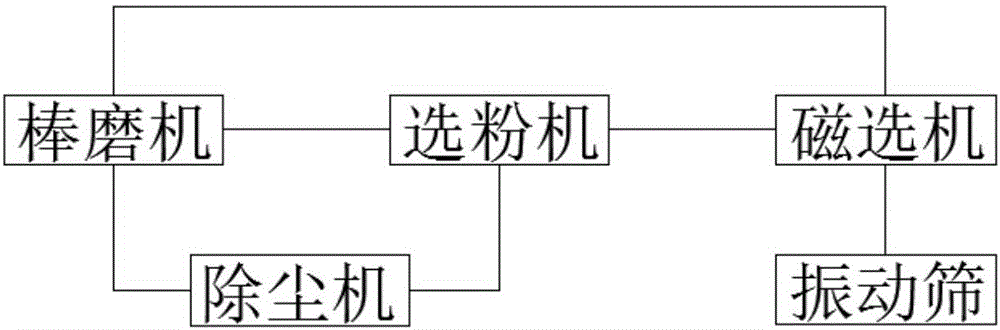

[0026] Steel slag with an average iron content of 15% enters the rod mill for crushing. The rod mill and the air box pulse dust collector are connected with the air box pulse dust collector through the air flow channel, and are equipped with a fan. The fan can guide the dust in the rod mill through the airflow pipe into the air box pulse dust collector for filtration, and the steel slag powder is filtered out. The crushed steel slag blocks crushed by the rod mill are transported to the V-type powder separator through the conveyor belt. The V-type powder classifier further separates the steel slag powder mixed in the crushed steel slag block, and also enters the air box pulse dust collector through the air flow channel to filter out the steel slag powder. So far the steel slag powder has all been filtered out, and its diameter is less than 0.3mm. The remaining crushed steel slag in the V-type classifier is transported to the rotating magnetic drum by the conveyor belt. Durin...

Embodiment 2

[0028] The difference from Example 1 is that the object of purification is steel slag with an average iron content of 20%, and the high-grade slag steel selected by the rotary magnetic drum has an iron content greater than 35%, and the process is the same.

Embodiment 3

[0030] The difference from Example 1 is that the object of purification is steel slag with an average iron content of 25%, and the high-grade slag steel selected by the rotary magnetic drum has an iron content greater than 40%, and the process is the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com