Uniform gluing mechanism of hard capsule gluing and sealing machine

A technology of hard capsules and glue seals, which is applied in capsule transportation, devices for coating liquid on the surface, drug delivery, etc. It can solve the problems of affecting the shelf life of capsules and drug effects, poor sealing performance of capsules, and moisture in drugs, etc. The thickness of the glue is uniform, the sealing performance is good, and the storage time is prolonged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

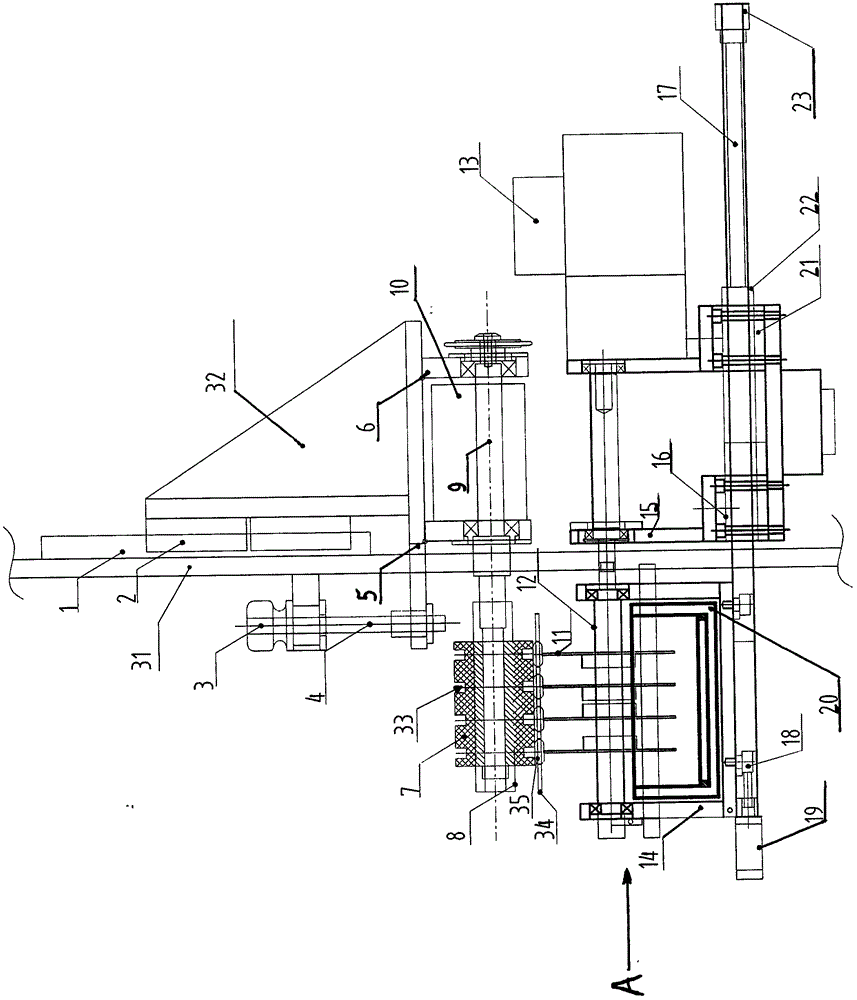

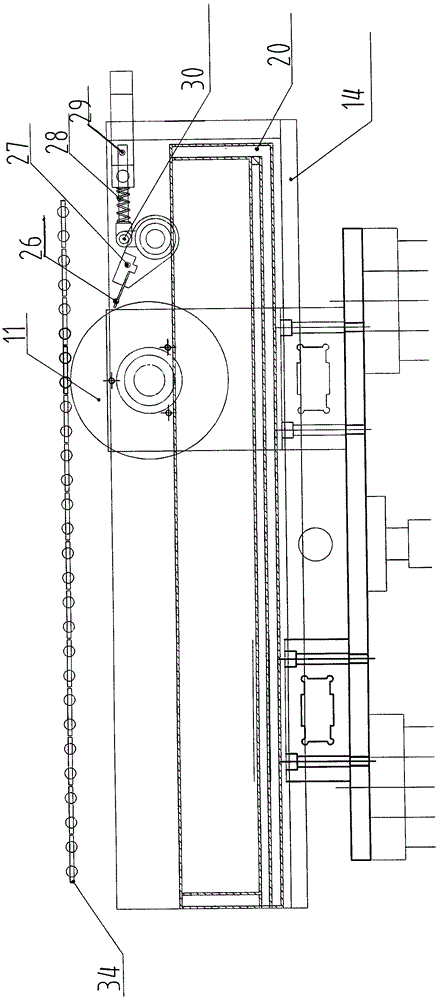

[0009] refer to figure 1 , figure 2 As can be seen, the uniform gluing mechanism of the hard capsule gluing and sealing machine of the present invention includes a frame 31, a gluing wheel 11, a gluing wheel rotation control device, and a gluing device, and rubber rollers are arranged above the gluing wheel 11 7. The rubber roller 7 is connected to the rubber roller rotation control device mounted on the frame 31, and the rubber roller 7 has a groove 33 corresponding to the wheel circumference position of the rubber roller 11 (it faces the glue roller of the capsule. seal, so that the rubber roller cannot touch the glue seal position of the capsule). According to the size of the capsule, it is convenient to adjust the position between the rubber roller and the capsule, the lifting platform 5 is housed on the rubber roller rotation control device (the rubber roller rotating bearing seat 6), and one side of the lifting platform 5 is equipped with Lifting screw rod 4, support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com