A capacitor pressure regulating type copper extruded pull track

An extrusion molding and pressure regulating technology, applied in the direction of metal extrusion, metal extrusion control equipment, metal processing equipment, etc., can solve cumbersome problems, avoid relative sliding, reduce the probability of extrusion deformation or even damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

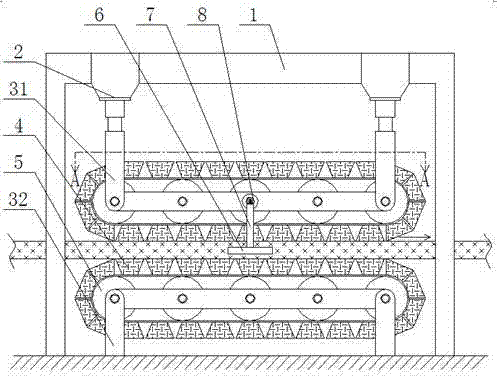

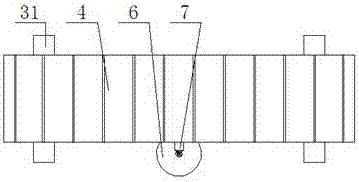

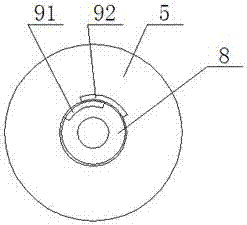

[0020] refer to Figure 1 to Figure 4 , Figure 1 to Figure 4 It is a structural schematic diagram of a specific embodiment of the present invention.

[0021] like Figure 1 to Figure 4 As shown, a capacitor pressure regulating type copper extruded pull track includes a base, a track assembly, a bracket assembly, and a control assembly. The track assembly includes two sets of traction tracks 4, upper and lower, and is used to support the The runner 5 of the traction crawler 4, the profile is located between two groups of the traction crawler 4; the bracket assembly includes a fixed bracket 32 for fixing the runner 5 of one group of the traction crawler 4, and for Fix the movable support 31 of the described runner 5 of another set of traction crawlers 4, and be used to connect and lift the lifting device 2 of the described movable support 31; The fixed support 32 and the described lifting device 2 are all fixed It is fixedly arranged on the base 1 or relative to the base 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com