Method for eliminating residual thermal stress of hard alloy cutter

A technology of residual thermal stress and cemented carbide, which is applied in the field of eliminating thermal stress of cutting tool materials, can solve the problems of difficult process control, low efficiency, and difficult to be widely promoted, and achieve simple equipment, low overcoming efficiency, and high process controllability efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

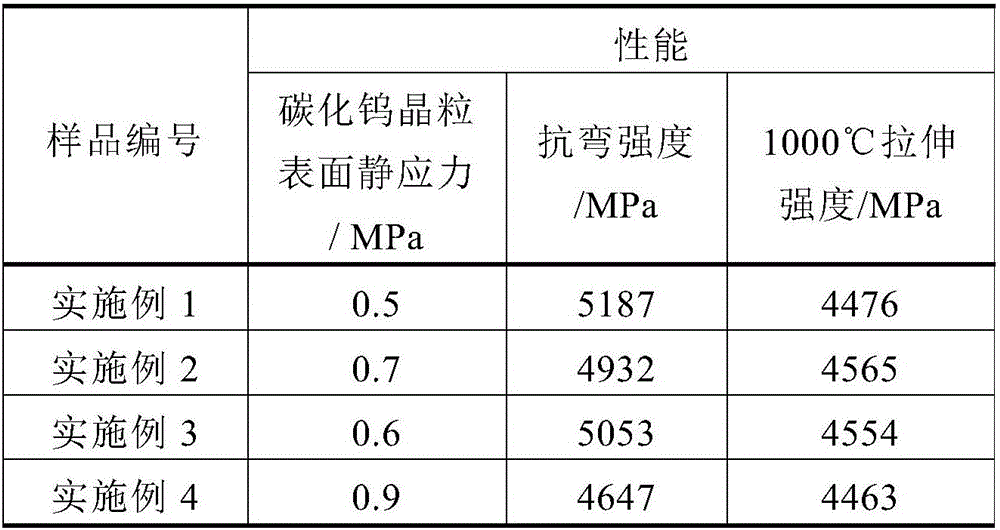

Examples

Embodiment 1

[0020] (1) Use a fine grinder to trim the flatness of the formed and sintered WC-11Co-2.1TaC cemented carbide tool sample with a size of 20mm×5mm×5mm, and then put it into a cold-press mold made of surface-hardened bearing steel .

[0021] (2) Load the cold-press mold equipped with the cemented carbide tool sample into the press for pre-compression, the pressure direction is parallel to the minimum cross-section of the sample, the pressure increase rate is 150MPa / min, the pressure is increased to 500MPa, and the pressure is maintained for 10 seconds; Boost the pressure to 1100MPa, the boost rate is 180MPa / min, continue to boost the pressure to 2000MPa at 200MPa / min, and keep the pressure for 70 seconds; the pressure is reduced in two stages, the first stage is 900MPa, the rate is 100MPa / min, the second stage is 0MPa, the rate 150MPa / min.

[0022] (3) Perform 10 cyclic pressings on the cemented carbide tool sample according to the process parameters in step (2), with an interv...

Embodiment 2

[0025] (1) Use a fine grinder to trim the flatness of the formed and sintered WC-11Co-2.1TaC cemented carbide tool sample with a size of 20mm×5mm×5mm, and then put it into a surface-hardened bearing steel cold-press mold after trimming.

[0026] (2) Load the cold-press mold equipped with the cemented carbide tool sample into the press for pre-compression, the pressure direction is parallel to the minimum cross-section of the sample, the pressure increase rate is 170MPa / min, the pressure is increased to 530MPa, and the pressure is maintained for 10 seconds; Boost the pressure to 1200MPa, the boost rate is 190MPa / min, continue to boost the pressure to 2000MPa at 200MPa / min, keep the pressure for 110 seconds; decompress in two stages, the first stage is 1000MPa, the rate is 100MPa / min, the second stage is 0MPa, the rate 150MPa / min.

[0027] (3) According to the process parameters in step (2), perform 9 cycles of pressing on the cemented carbide tool sample with an interval of 20 ...

Embodiment 3

[0030] (1) Use a fine grinder to trim the flatness of the formed and sintered WC-11Co-2.1TaC cemented carbide tool sample with a size of 20mm×5mm×5mm, and then put it into a surface-hardened bearing steel cold-press mold after trimming.

[0031] (2) Load the cold-press mold equipped with the cemented carbide tool sample into the press for pre-compression, the pressure direction is parallel to the minimum cross-section of the sample, the pressure increase rate is 160MPa / min, the pressure is increased to 440MPa, and the pressure is maintained for 10 seconds; Boost the pressure to 1000MPa, the boost rate is 150MPa / min, continue to boost the pressure to 1800MPa at 200MPa / min, and keep the pressure for 140 seconds; the pressure is reduced in two stages, the first stage is 1000MPa, the rate is 100MPa / min, the second stage is 0MPa, the rate 150MPa / min.

[0032] (3) Carry out 12 cyclic pressings on the cemented carbide tool sample according to the process parameters in step (2), with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com