Automatic deburring machine

A deburring machine and deburring technology, applied in the field of automation, can solve problems such as time-consuming and labor-intensive, and achieve the effect of high efficiency and labor cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical problems solved by the present invention, the technical solutions adopted and the technical effects achieved more clear, the technical solutions of the present invention will be further described below in conjunction with the drawings and specific implementations.

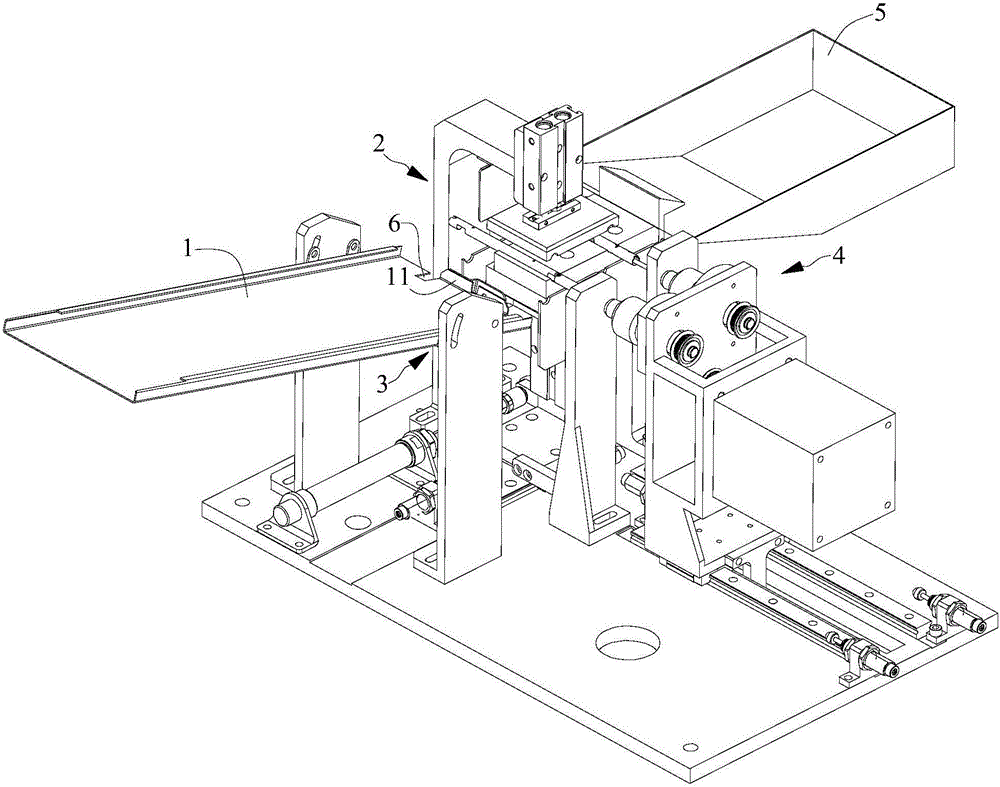

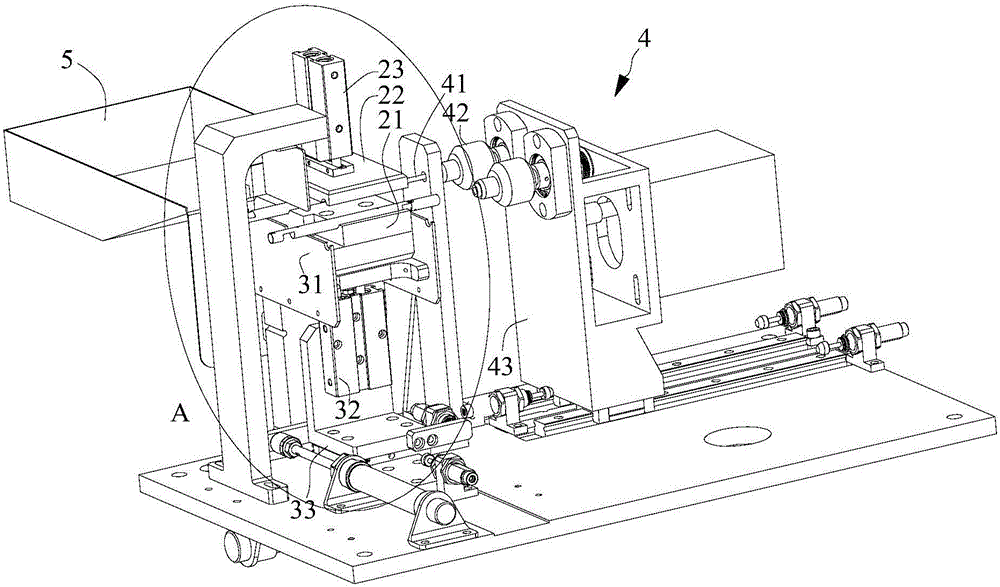

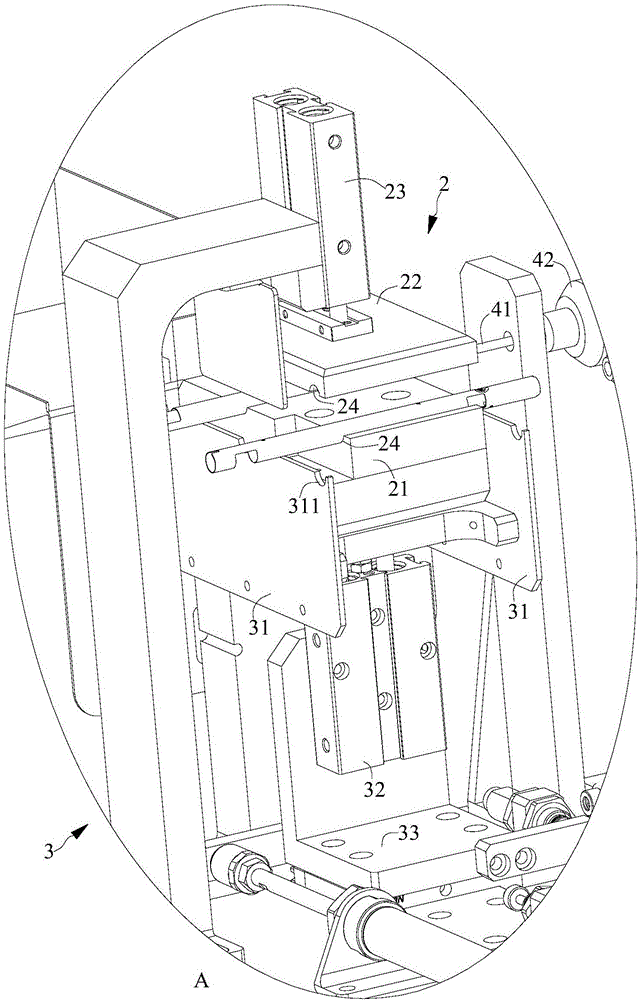

[0024] The embodiment of the present invention provides an automatic deburring machine, which includes a storage table 1 for storing materials, a work table 2 for fixing materials, and a feeding device for transporting materials from the storage table 1 to the work table 2. 3. The feeding device 3 includes a feeding plate 31, a vertical movement mechanism 32 that drives the feeding plate 31 to move up and down, and a horizontal movement mechanism 33 that drives the feeding plate 31 to move back and forth. The feeding plate 31 is provided with a limit portion 311 that limits the material. For products that are inconvenient to use the conveyor belt, the automatic deburring machine ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com