Parallel type underwater vectored thruster

A vector thruster, parallel technology, applied in the direction of underwater ships, underwater operation equipment, ships, etc., can solve the problems of submersibles unable to meet mission requirements, weakened rudder maneuverability, etc., to improve structural mechanical properties and facilitate movement. Control, high stiffness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

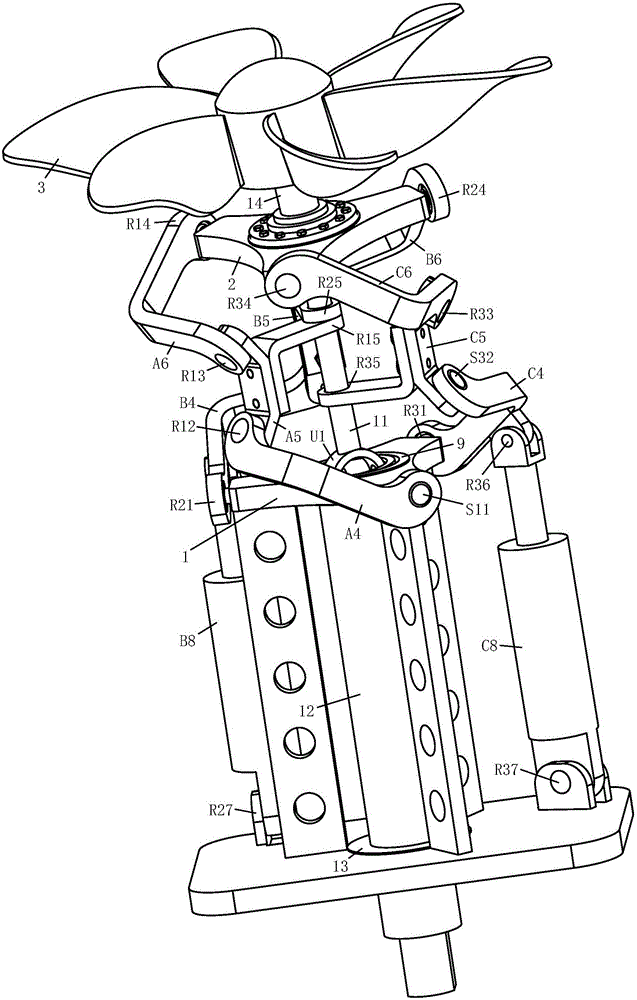

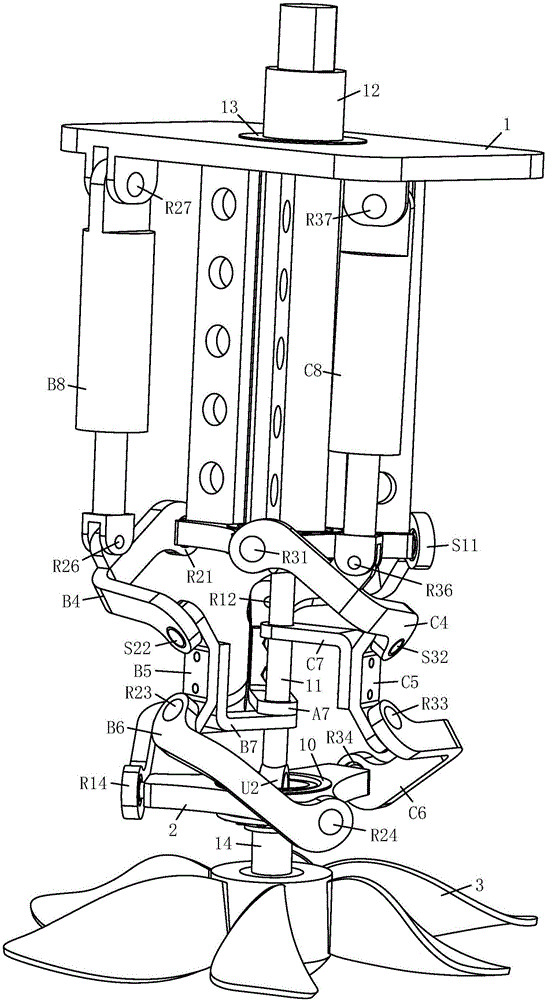

[0024] like figure 1 , figure 2 and Figure 5 As shown, it is the first embodiment disclosed by the present invention, a parallel underwater vector thruster, which mainly includes a frame 1, a reversing table 2, three motion branch chains connecting the frame 1, and the reversing table 2, and the three motions The specific connection method of the branch chain is as follows:

[0025] The first motion branch chain is composed of lower link A4, middle link A5 and upper link A6. One end of the lower link A4 is connected to the frame 1 through the ball pair S11, and the other end of the lower link A4 is connected to the middle link A5. Connected by the rotating pair R12, one end of the upper link A6 is connected with the middle connecting rod A5 through the rotating pair R13, and the other end of the upper connecting rod A6 is connected with the reversing table 2 through the rotating pair R14; the second kinematic branch chain is connected by the lower link B4 , the middle lin...

Embodiment 2

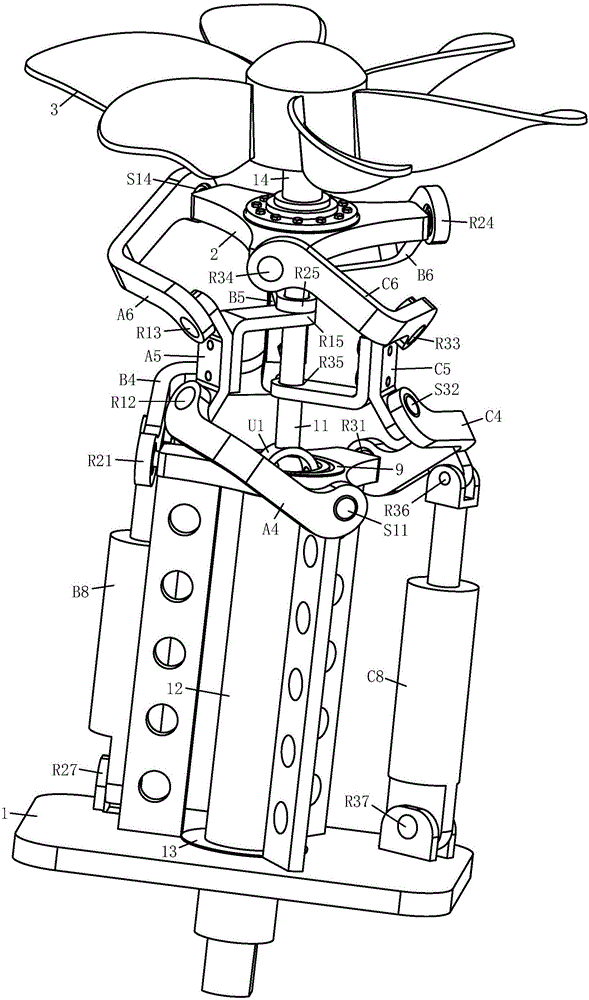

[0031] like image 3 , Figure 4 and Figure 5 As shown, it is the second embodiment disclosed by the present invention, a parallel underwater vector thruster, which mainly includes frame 1, reversing table 2, three motion branch chains connecting frame 1 and reversing table 2, and three motion The specific connection method of the branch chain is as follows:

[0032] The first motion branch chain is composed of lower link A4, middle link A5 and upper link A6. One end of the lower link A4 is connected to the frame 1 through the ball pair S11, and the other end of the lower link A4 is connected to the middle link A5. Connected by the rotary pair R12, one end of the upper link A6 is connected with the middle link A5 through the rotary pair R13, and the other end of the upper link A6 is connected with the reversing table 2 through the ball pair S14; the second kinematic branch chain is connected by the lower link B4 , the middle link B5 and the upper link B6, one end of the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com