High-tenacity and high-transparency polylactic acid and preparation method thereof

A technology of polylactic acid and high toughness, which is applied in the field of preparation of high toughness and high transparency polylactic acid, can solve the problems of intensifying visible light scattering and reducing the transparency of products, and achieves low requirements for preparation equipment, high strength, and simple and effective preparation methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

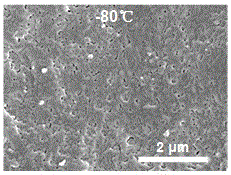

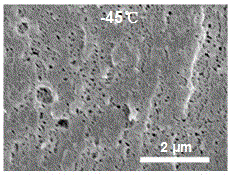

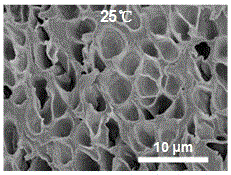

[0034] Measure polylactic acid and chloroform (solvent) according to Example 1 to Example 5 in Table 1, mix and dissolve to prepare a polylactic acid solution, scrape the film on a glass plate, and place it in ethanol (non-solvent) at different temperatures to obtain a solution containing Polylactic acid with holes.

[0035] After vacuum drying to remove residual solvents and non-solvents, tensile test samples were prepared with dumbbell-shaped cutters. Tensile properties were tested using a universal testing machine. The test temperature is 25°C, the relative humidity is 40%, and the tensile speed is 5mm / min. The test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Tensile toughness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com