Front-drive automobile transmission

A technology of automobile transmission and front drive, which is applied in the direction of transmission parts, shafts, shafts and bearings, and can solve problems such as easy noise, poor journal stiffness, and easy deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

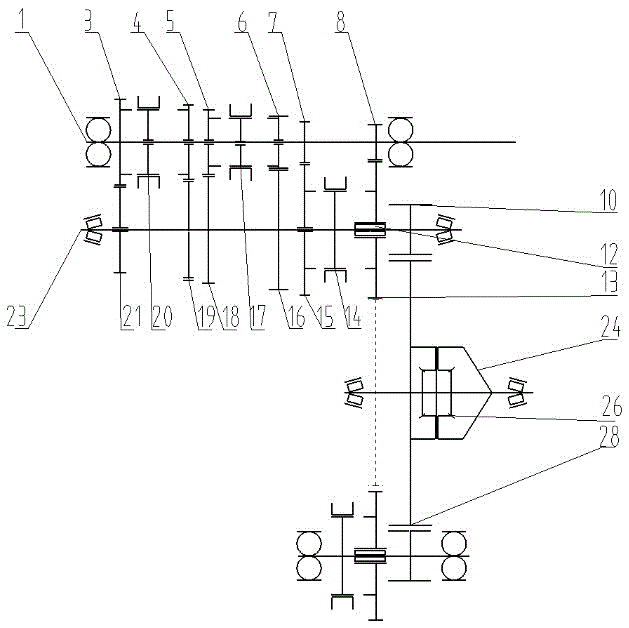

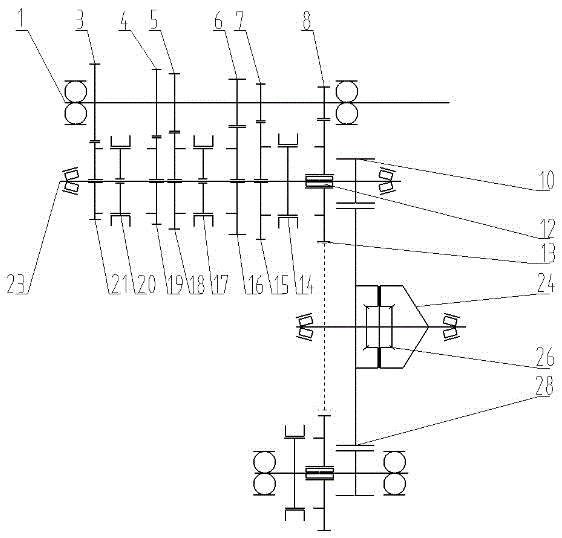

[0011] see figure 2 , the front-drive automobile transmission of the present invention comprises: high-speed synchronizer assembly 20 and third and fourth gear synchronizer assembly 17, input shaft 1 and intermediate shaft 23 arranged in parallel with each other at a fixed distance, assembled on the input shaft 1 from left to right Shaft sixth gear 3, input shaft fifth gear 4, input shaft fourth gear 5, input shaft third gear 6, input shaft second gear 7 and input shaft first gear 8; assembled on intermediate shaft 23 from left to right Intermediate shaft sixth gear 21, intermediate shaft fifth gear 19, intermediate shaft fourth gear 18, intermediate shaft third gear 16, intermediate shaft second gear 15, low speed synchronizer assembly 14, first gear needle bearing 12 and The intermediate shaft constant meshing gear 10, and the intermedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com